Ruthenium supported perovskite-type-oxide ammonia synthesis catalyst and preparation method thereof

A composite oxide and perovskite-type technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, preparation/separation of ammonia, etc., can solve low-temperature and low-pressure activity of ruthenium catalysts, etc. problems, achieve excellent catalytic activity, no loss of raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

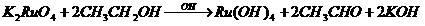

Method used

Image

Examples

Embodiment 1

[0019] Zr(NO 3 ) 4 .5H 2 O:Ba(NO 3 ) 2 : A mixture of citric acid with a molar ratio of 1:1:2.0 was dissolved in a small amount of distilled water to obtain a colorless clear viscous liquid. The solution was slowly heated in a water bath at 80°C for 4 h to evaporate excess water, and then heated at a constant temperature of 90°C for 12 h to promote the gelation of the mixture. Finally, the obtained yellow gel was calcined at 300 °C for 1 h to obtain the precursor, and then calcined at 700 °C for 5 h to obtain BaZrO 3 carrier material. The active component ruthenium was impregnated into the carrier by equal volume impregnation method, and then reduced with absolute ethanol. The active component Ru accounted for 4% of the mass fraction of the carrier. The catalyst is 3 MPa, the space velocity is 10000 h -1 At 375°C, 400°C and 425°C, the outlet ammonia concentrations were 3.94%, 6.80% and 8.33%, respectively. Ammonia synthesis catalyst Ru / Al with 5wt% ruthenium content re...

Embodiment 2

[0021] BaZrO 3 The loading method of carrier and ruthenium is the same as embodiment 1, but the precursor of Zr is ZrO(NO 3 ) 2 . The outlet ammonia concentrations of the tested catalysts under the same conditions were 3.84%, 6.56% and 8.24%, respectively.

Embodiment 3

[0023] BaZrO 3 The loading method of carrier and ruthenium is the same as embodiment 1, but the precursor of Ba in the preparation process is Ba(CH 3 COO) 2 . The outlet ammonia concentrations of the tested catalysts under the same conditions were 3.72%, 5.94% and 7.86%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com