Desulfurized ash residue mixed dry mortar

A technology for desulfurization ash and dry-mixed mortar, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem that there is no research report on the production of desulfurization ash and dry-mix mortar, and achieves improved mechanical properties. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

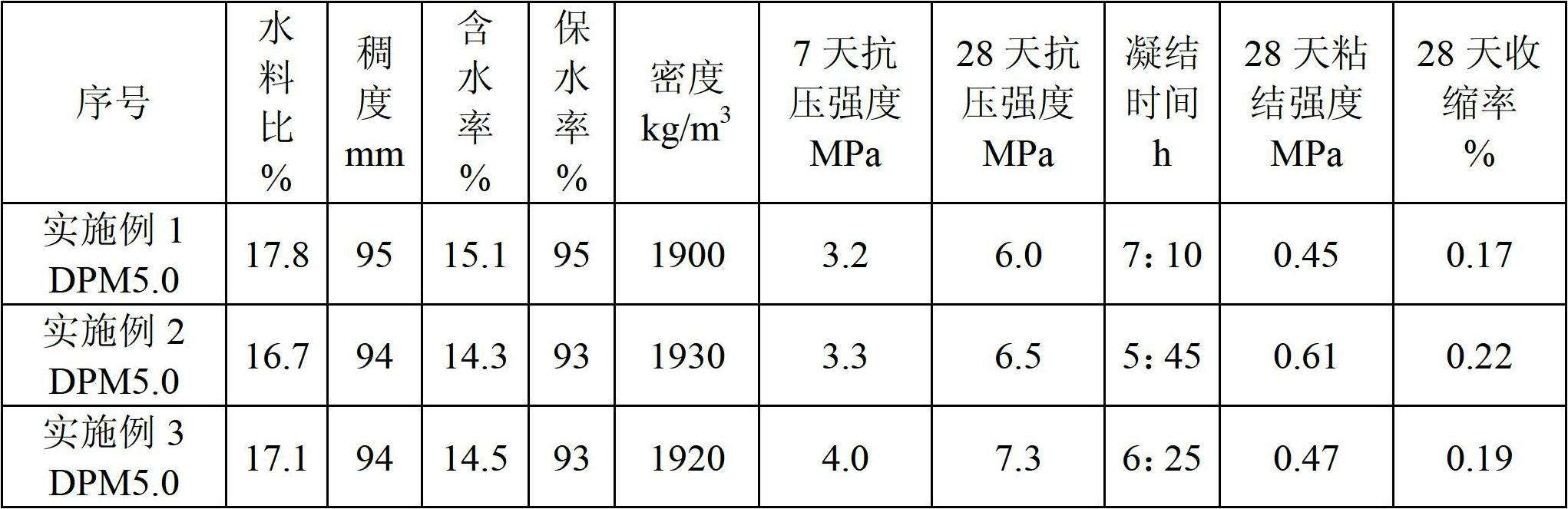

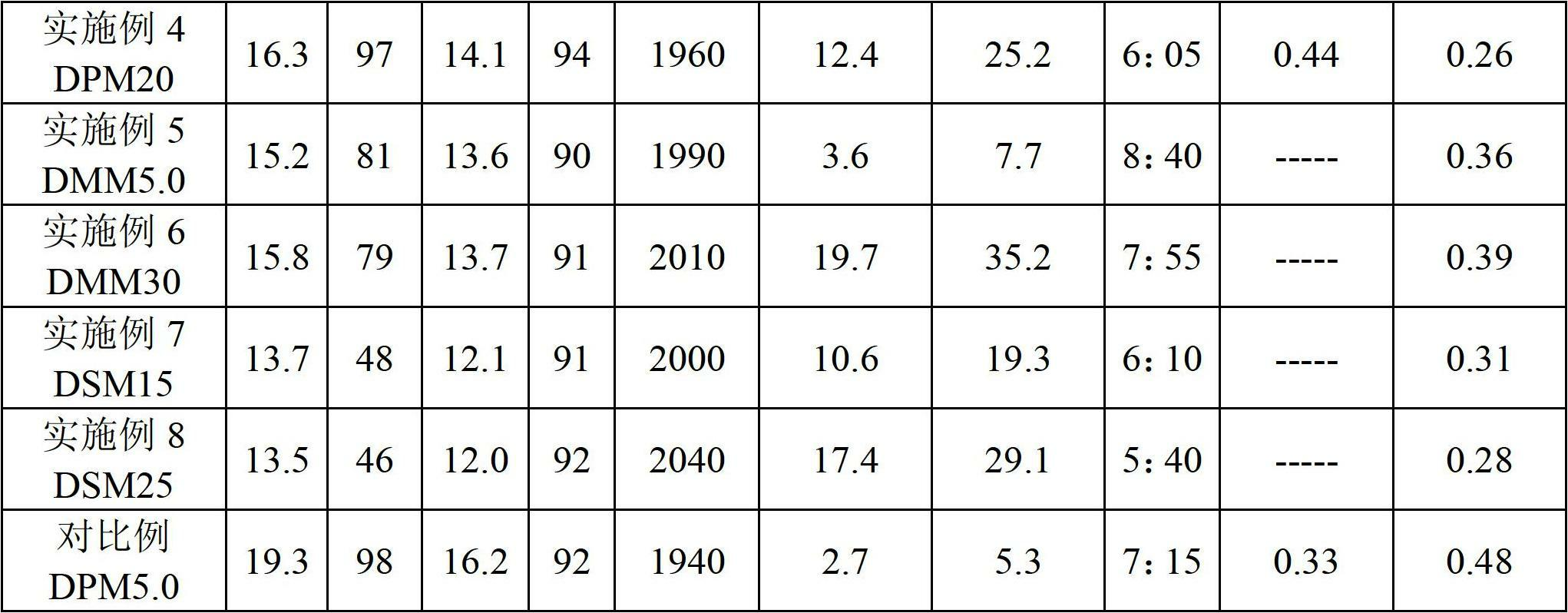

Embodiment 1

[0019] Formula: 125kg of cement, 60kg of desulfurization ash, 780kg of fine aggregate, 25kg of water-retaining thickening material, 0.9kg of polycarboxylate superplasticizer, 0.28kg of sodium lauryl sulfate, and 1.4kg of accelerator.

[0020] The cement used is ordinary Portland cement P·O 42.5, and the water-retaining thickening material is bentonite, first-grade fly ash, hydroxypropyl methylcellulose ether, and redispersible latex powder. The weight of the four The ratio range is 4.5:5.4:0.13:0.07.

[0021] Preparation method: mix the early-strength water-reducing agent, foaming agent, and quick-setting agent to obtain the mixed material; mix the fine aggregate, cement, water-retaining thickening material, and desulfurization ash, and then add the mixed material and mix evenly.

Embodiment 2

[0023] Formula: 130kg of cement, 50kg of desulfurization ash, 790kg of fine aggregate, 25kg of water-retaining thickening material, 0.8kg of naphthalene-based superplasticizer, 0.25kg of polyurethane foaming agent, and 1.4kg of accelerator.

[0024] The cement used is Portland cement P·I 42.5, and the water-retaining thickening material is bentonite, first-grade fly ash, hydroxypropyl methylcellulose ether, and redispersible latex powder. The weight ratio of the four The range is 4.0:5.8:0.1:0.1.

[0025] The preparation method is the same as in Example 1.

Embodiment 3

[0027] Formula: 140kg of cement, 55kg of desulfurization ash, 800kg of fine aggregate, 20kg of water-retaining thickening material, 0.8kg of polycarboxylate superplasticizer, 0.23kg of sodium lauryl sulfate, and 1.3kg of accelerator.

[0028] The cement used is Portland cement P·Ⅱ42.5. The water-retaining thickening material is a mixture of bentonite, primary fly ash, hydroxypropyl methylcellulose ether, and redispersible latex powder, and the weight ratio range of the four is 4.9:5.0:0.15:0.05.

[0029] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com