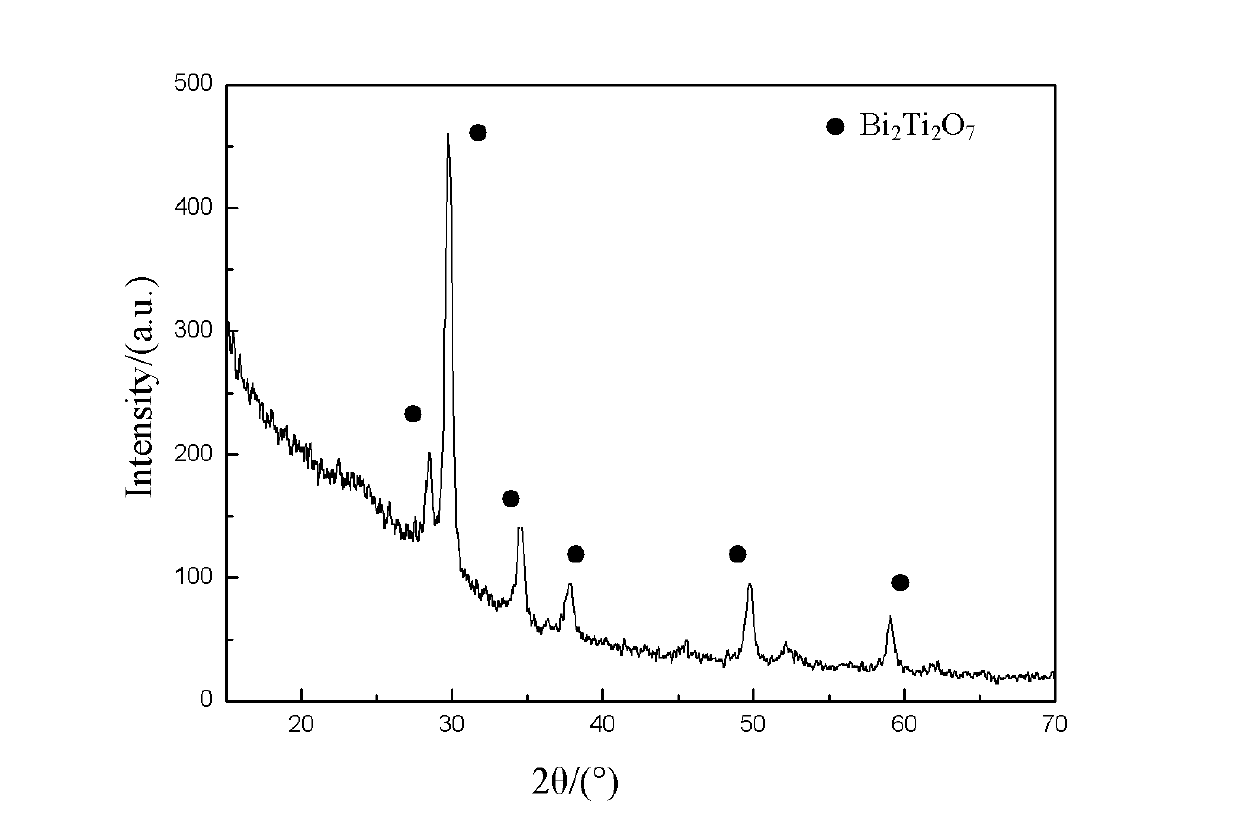

Method for manufacturing pyrochlore phase bismuth titanate functional films on surfaces of glass substrates

A glass substrate, phase bismuth titanate technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the complex vacuum environment and process system of process equipment, film uniformity and thickness difficult to control , high cost and other problems, to achieve the effect of highly ordered bond formation, less defects and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

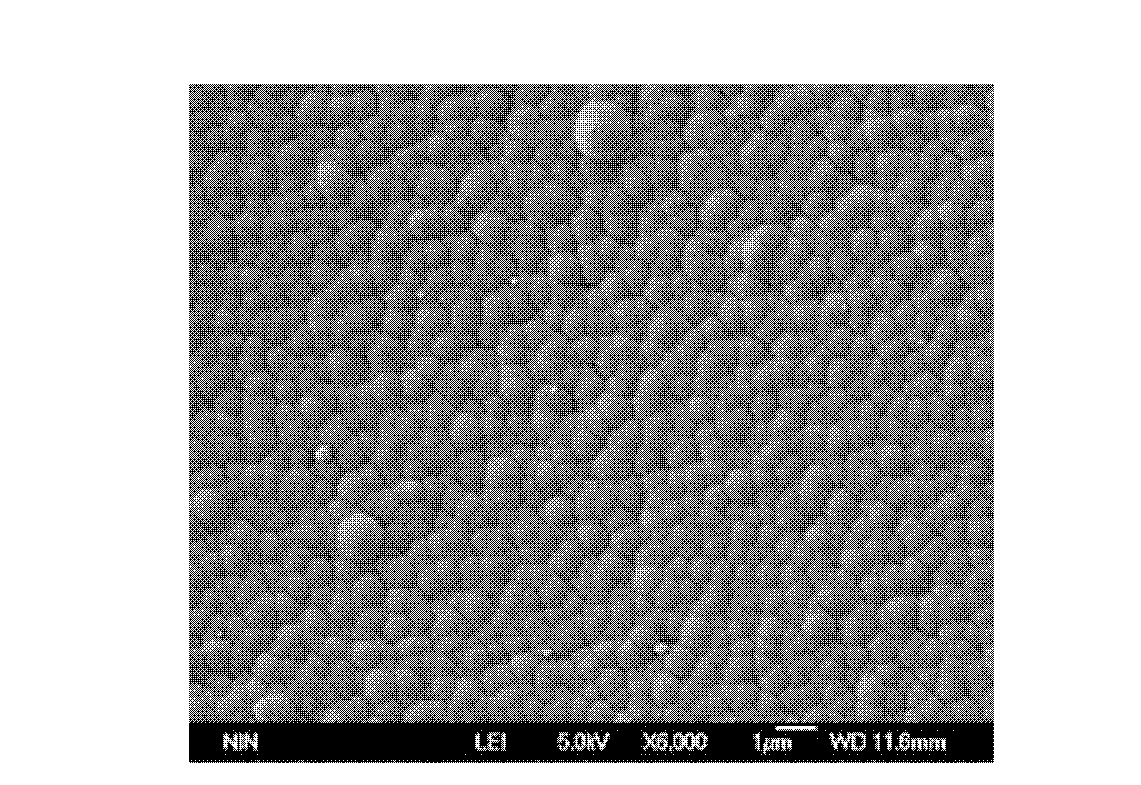

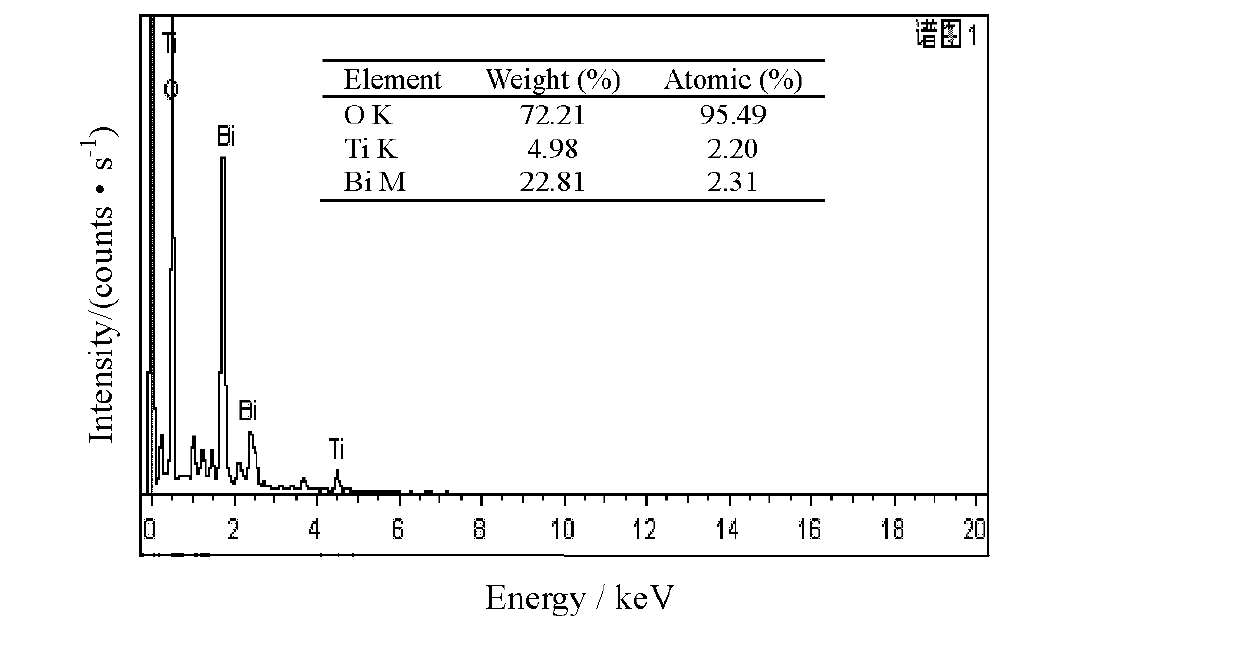

Embodiment 1

[0019] A method for preparing a pyrochlore-phase bismuth titanate functional thin film on the surface of a glass substrate of the present invention comprises the following steps:

[0020] Step 1: Functionalization of the substrate. The glass substrate was ultrasonically washed with deionized water, absolute ethanol and acetone for 10 minutes respectively, and then dried in nitrogen gas and then soaked in OTS (octadecyltrichlorosilane) and toluene (the volume ratio of OTS and toluene was 1:99). Deposit in the mixed solution for 30s-20min to obtain an OTS monolayer film, then bake at 120°C for 5 minutes to remove the residual solution on the surface, and then irradiate with ultraviolet light for 40min to realize the functionalization of the substrate surface.

[0021] Step 2: Configure the precursor solution. Considering that Bi is volatile at high temperature, the precursor solution was prepared with a Bi:Ti molar ratio of 1.20:1. Bi(NO 3 ) 3 ·5H 2 O is dissolved in a mixe...

Embodiment 2

[0025] A method for preparing a pyrochlore-phase bismuth titanate functional thin film on the surface of a glass substrate of the present invention comprises the following steps:

[0026] Step 1: Functionalization of the substrate. The glass substrate was ultrasonically washed with deionized water, absolute ethanol and acetone for 10 minutes respectively, and then dried in nitrogen gas and then soaked in OTS (octadecyltrichlorosilane) and toluene (the volume ratio of OTS and toluene was 1:99). Deposit in the mixed solution for 30s-20min to obtain an OTS monolayer film, then bake at 120°C for 5 minutes to remove the residual solution on the surface, and then irradiate with ultraviolet light for 40min to realize the functionalization of the substrate surface.

[0027] Step 2: Configure the precursor solution. Considering that Bi is volatile at high temperature, the precursor solution was prepared with a Bi:Ti molar ratio of 1.20:1. Bi(NO3 ) 3 ·5H 2 O is dissolved in a mixed ...

Embodiment 3

[0031] A method for preparing a pyrochlore-phase bismuth titanate functional thin film on the surface of a glass substrate of the present invention comprises the following steps:

[0032] Step 1: Functionalization of the substrate. The glass substrate was ultrasonically washed with deionized water, absolute ethanol and acetone for 10 minutes respectively, and then dried in nitrogen gas and then soaked in OTS (octadecyltrichlorosilane) and toluene (the volume ratio of OTS and toluene was 1:99). Deposit in the mixed solution for 30s-20min to obtain an OTS monolayer film, then bake at 120°C for 5 minutes to remove the residual solution on the surface, and then irradiate with ultraviolet light for 40min to realize the functionalization of the substrate surface.

[0033] Step 2: Configure the precursor solution. Considering that Bi is volatile at high temperature, the precursor solution was prepared with a Bi:Ti molar ratio of 1.20:1. Bi(NO 3 ) 3 ·5H 2 O is dissolved in a mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com