Method for extracting scutelloside and scutellarin from baikal skullcap root

A technology for baicalin and baicalein, which is applied in the field of extraction of baicalin and baicalein, can solve the problems of difficulty in realizing large-scale industrial production, low product purity, and high equipment requirements, and achieves avoiding the loss of raw materials and energy consumption. The effect of high purity and fast separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

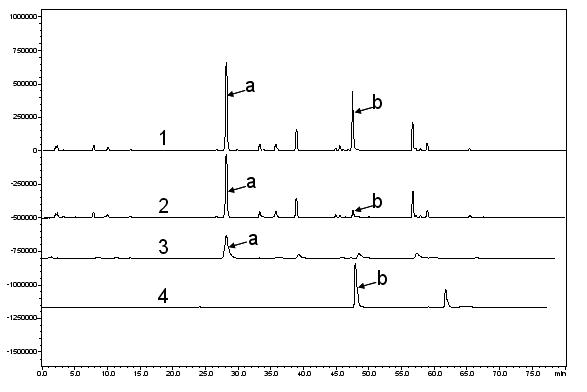

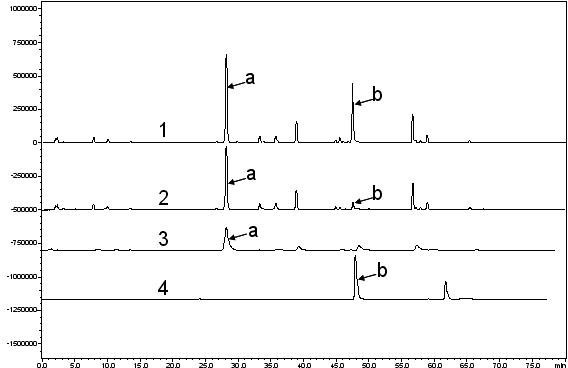

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] (1) Solvent ultrasonic extraction: Weigh 1.0 g of Scutellaria baicalensis root powder, add 100 ml of extraction solvent, add formic acid, adjust the pH to 5, perform ultrasonic extraction for 30 min, and centrifuge at 10,000 rpm for 5 min to obtain the extract;

[0022] The extraction solvent is a mixture of acetonitrile and water, wherein the volume ratio of acetonitrile and water is 4:1;

[0023] (2) Fe 3 o 4 Magnetic nanoparticle adsorption: add 3.0 g Fe to the extract obtained in step (1) 3 o 4 Magnetic nanoparticles, stirred, ultrasonically dispersed for 2 min, shaken on a constant temperature oscillator at 25°C for 20 min, separated by a magnet, so that the solution was divided into upper and lower phases, and baicalin and baicalein were selectively adsorbed on the Fe in the lower layer. 3 o 4 Nanoparticle surface;

[0024] (3) Desorption: blot the supernatant, and desorb to Fe 3 o 4 Add 100 ml of baic...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] (1) Solvent ultrasonic extraction: Weigh 5.0 g of Scutellaria baicalensis root powder, add 800 ml of extraction solvent, add acetic acid, adjust the pH to 4, ultrasonically extract for 30 min, and centrifuge at 10,000 rpm for 5 min to obtain the supernatant; the extraction solvent is The mixture of methanol and water, the volume ratio of methanol and water is 3: 1;

[0033] (2) Fe 3 o 4 Magnetic nanoparticle adsorption: Add 20.0 g Fe to the supernatant obtained in step (1) 3 o 4 Magnetic nanoparticles, stirred, ultrasonically dispersed for 2 min, shaken on a constant temperature oscillator at 25°C for 20 min, separated by a magnet, so that the solution was divided into upper and lower phases, and baicalin and baicalein were selectively adsorbed on the Fe in the lower layer. 3 o 4 Nanoparticle surface;

[0034] (3) Desorption: blot the supernatant, and desorb to Fe 3 o 4 Add 800 ml of baicalin eluent to the n...

Embodiment 3

[0038] This embodiment includes the following steps:

[0039] (1) Solvent ultrasonic extraction: Weigh 10.0 g of Scutellaria baicalensis root powder, add 2000 ml of extraction solvent, then add formic acid, adjust the pH to 3, ultrasonically extract for 30 min, and centrifuge at 10000 rpm for 5 min to obtain the supernatant; the extraction solvent It is a mixture of acetone and water, the volume ratio of acetone and water is 4: 1;

[0040] (2) Fe 3 o 4 Magnetic nanoparticles adsorption: add 40 g Fe to the supernatant obtained in step (1) 3 o 4 Magnetic nanoparticles, stirred, ultrasonically dispersed for 2 min, shaken on a constant temperature oscillator at 25°C for 20 min, separated by a magnet, so that the solution was divided into upper and lower phases, and baicalin and baicalein were selectively adsorbed on the Fe in the lower layer. 3 o 4 Nanoparticle surfaces;

[0041] (3) Desorption: blot the supernatant, and desorb to Fe 3 o 4 Add 2000 ml of baicalin eluent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com