Preparation method of straw-based high-water-absorption resin with semi-interpenetrating network structure

A technology of super absorbent resin and straw, applied in chemical and environmental fields, can solve the problems of low strength, poor salt resistance and environmental friendliness, etc., and achieve the effects of improving product strength, good water absorption and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

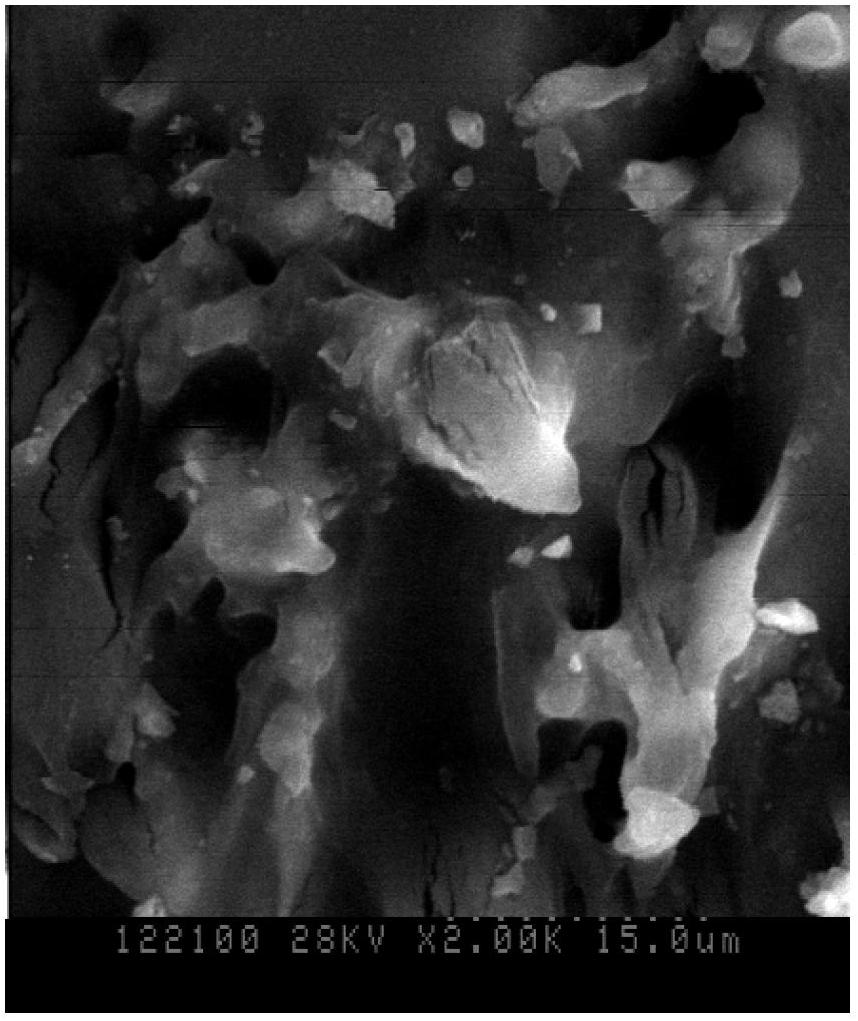

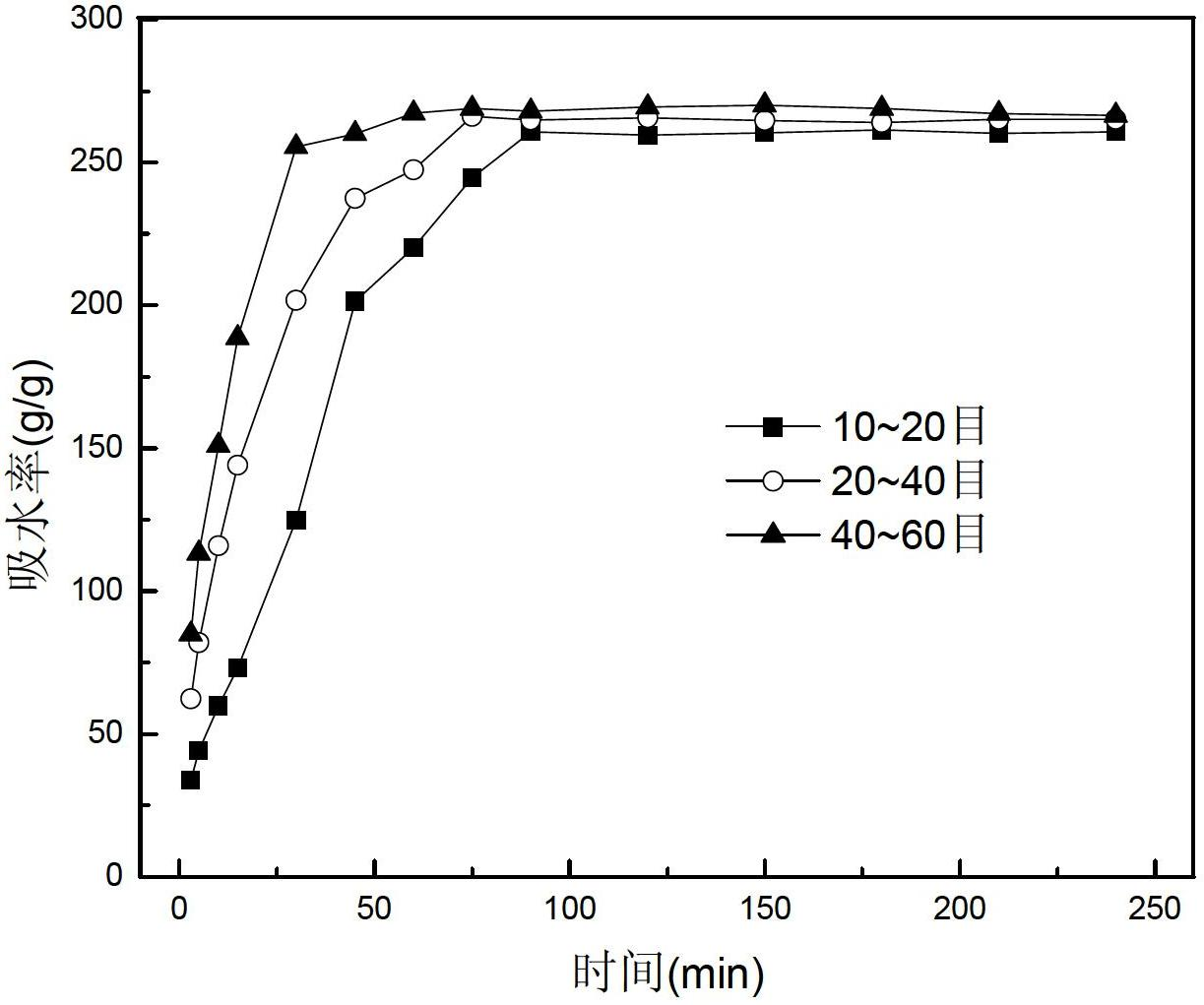

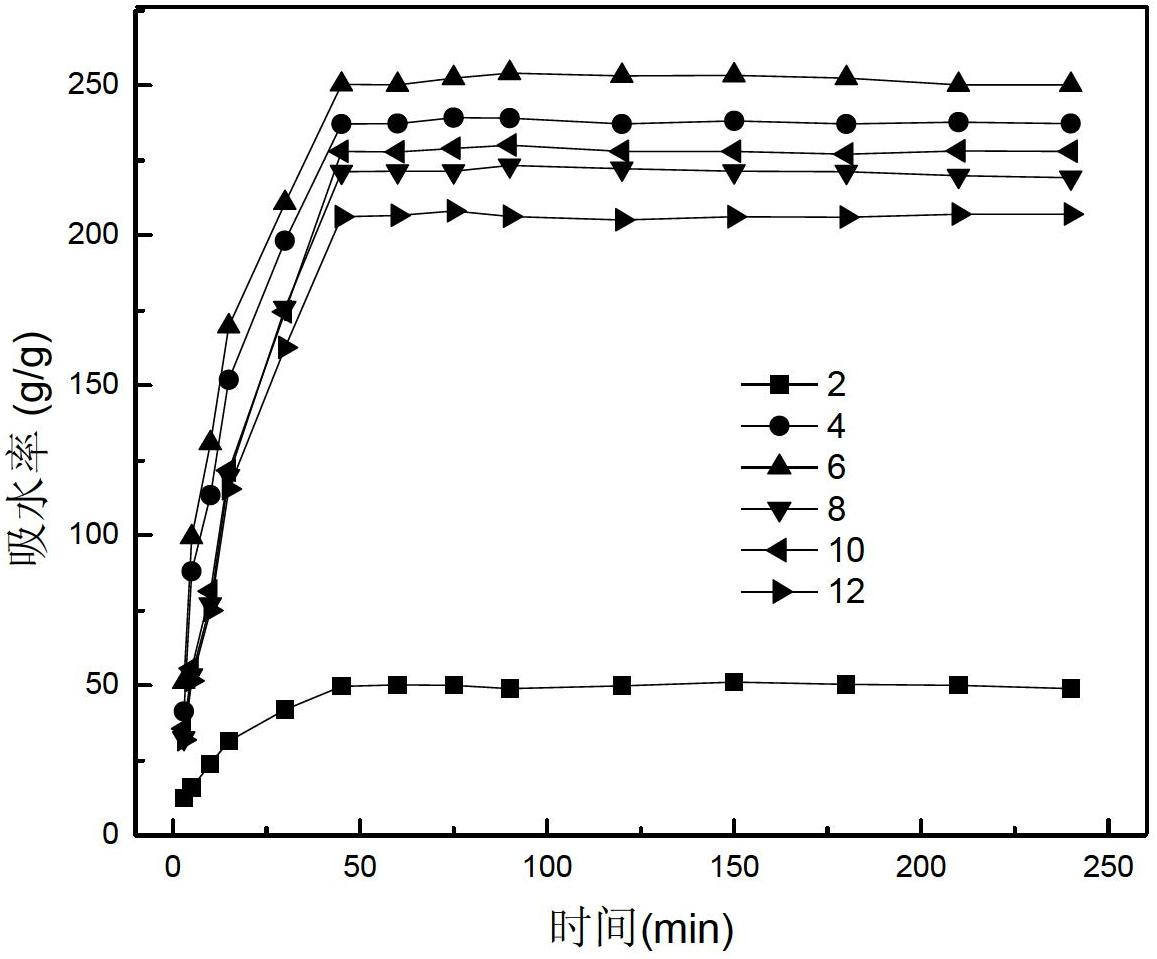

Image

Examples

Embodiment 1

[0029] Example 1. Preparation of straw-based superabsorbent resin with semi-interpenetrating network structure

[0030] (1) Wash the wheat straw and dry it at 70±5°C, then crush it and pass it through a 100-mesh sieve, and collect the sieved straw powder for later use;

[0031] (2) Soak the collected straw powder in ammonia water with a concentration of 10wt% for 48±5 hours, wherein the mass ratio of straw and ammonia water is 1:12, then suction filter and wash with water, and collect when the washed water is colorless Powder and dry at 70±5°C;

[0032] (3) Take the straw powder dried in step (2), treat it in 1mol / L nitric acid solution at 100±2°C for 45±5min, then filter it with suction and wash it with water until the washed water is colorless Collect the powder and dry it at 70±5°C; grind the dried powder with a mortar, pass through a 100-mesh sieve, and collect it for later use;

[0033] (4) Take 12ml of acrylic acid in a beaker, add 20ml of 6mol / L KOH solution to neutra...

Embodiment 2

[0036] Example 2. Preparation of straw-based superabsorbent resin with semi-interpenetrating network structure

[0037] As described in Example 1, the difference was that the amount of polyvinyl alcohol was changed: 20 ml of polyvinyl alcohol solution (concentration 60 mg / L) was added, and the reaction was stirred at 50° C. for 45 min. All the other operations, consumption are identical with embodiment 1.

[0038] It is determined that the obtained straw-based superabsorbent resin with a semi-interpenetrating network structure can reach a maximum water absorption rate of 225.12g / g, and a maximum salt water absorption rate of 23.64g / g.

Embodiment 3

[0039] Example 3. Preparation of straw-based superabsorbent resin with semi-interpenetrating network structure

[0040] As described in Example 1, the difference is that the reaction temperature has been changed:

[0041] Take 1.00 g of the straw powder obtained in step (3) and place it in a three-necked flask, add 10 ml of potassium persulfate solution (20 mg / L), and 4 ml of cerium ammonium nitrate solution (10 mg / L), and stir and react at 70 ° C for 15 min; Add 3.3ml of sodium sulfite solution (20mg / L) and 25.3ml of acrylic acid solution with a neutralization degree of 65% into the three-necked flask. After 15 minutes, add 33.3ml of polyvinyl alcohol solution (60mg / L), and stir and react at 70°C for 45 minutes; Add 2ml of N,N'-methylenebisacrylamide solution (20mg / L) into the three-necked flask, and stir the reaction at 70°C for 4h. All the other operations, consumption are identical with embodiment 1.

[0042] It is determined that the obtained straw-based superabsorbent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com