Manufacturing method of compound type super absorbent resin

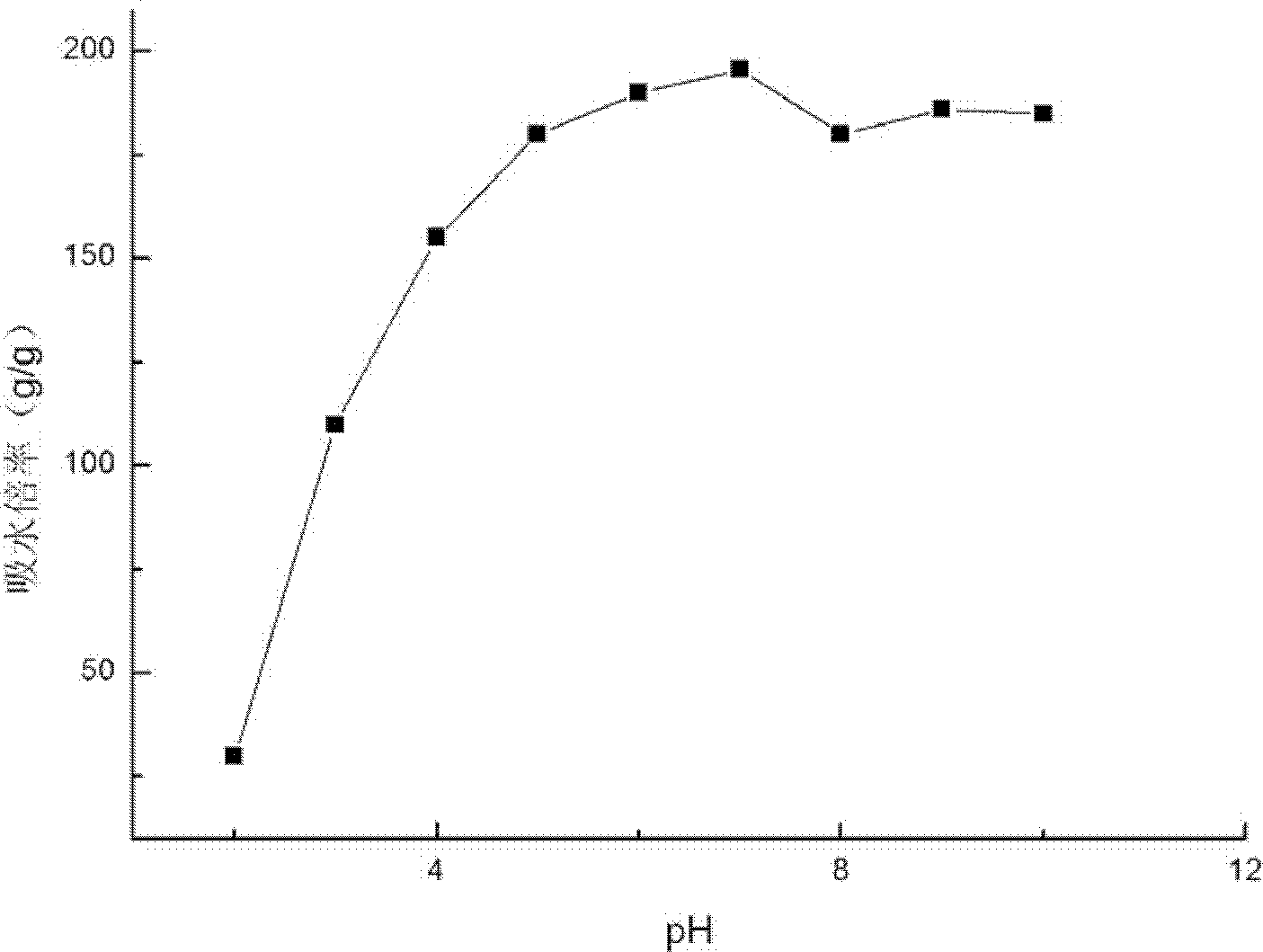

A superabsorbent resin and composite technology, applied in the chemical and environmental fields, can solve problems such as poor salt tolerance, high preparation temperature, and not easy to degrade, and achieve the effects of low cost, good water absorption, and large pH value application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

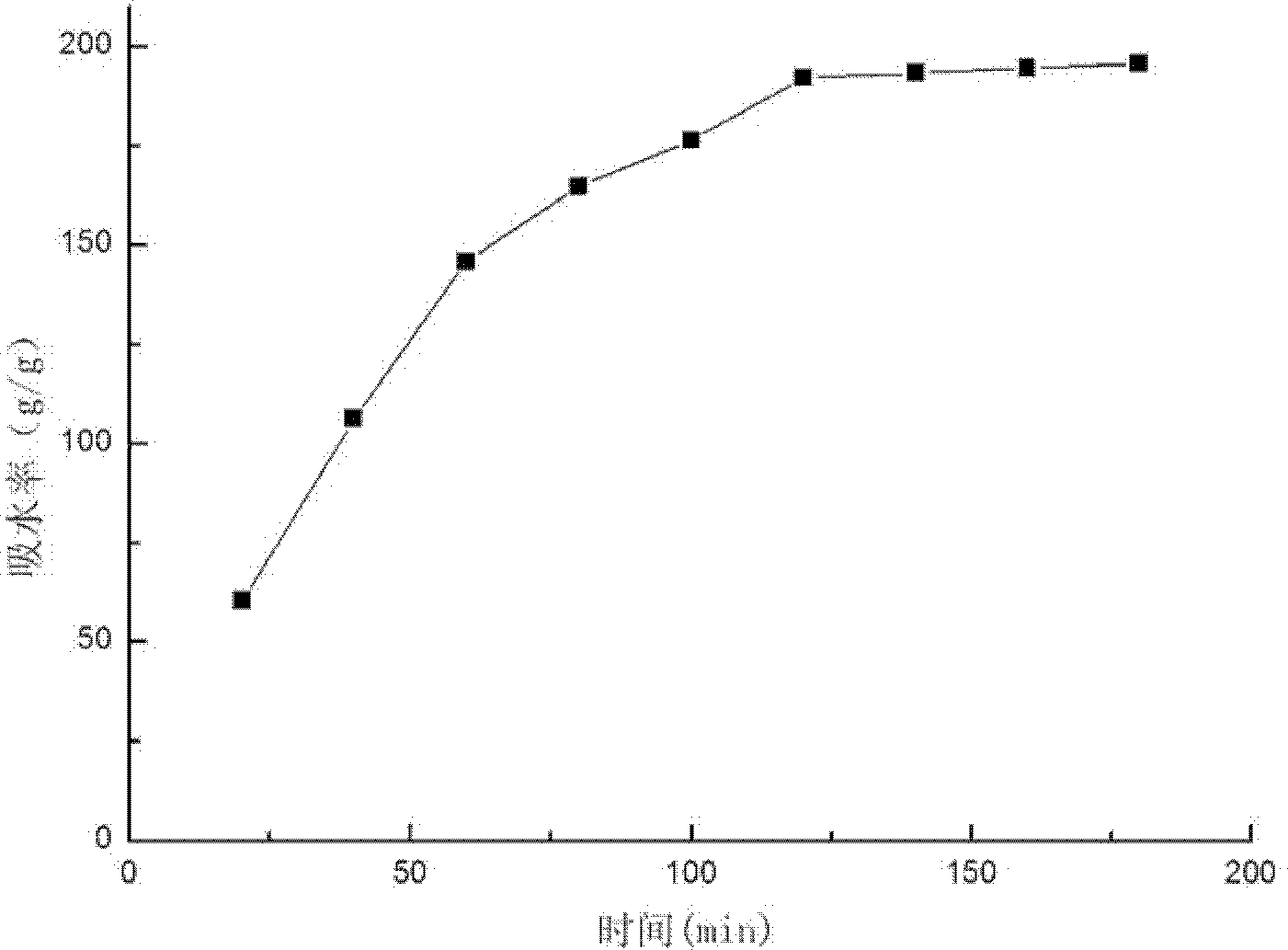

[0028] Embodiment 1: A kind of preparation method of superabsorbent resin, the steps are as follows:

[0029] (1) Wheat straw pretreatment: wash with water to remove the dirt and dust on the surface of the wheat straw. Dry it at 70°C, then pulverize it, sieve it with a 100-mesh sieve, weigh a certain amount of sieved wheat straw, add 12wt% ammonia water in the ratio of ammonia water quality: straw quality=12:1 , soaked for 48 hours, the soaked wheat stalks were suction filtered and washed and dried with distilled water; a certain amount of dried wheat stalks were taken and mixed with nitric acid solution (1mol / L) quality: straw quality=12:1 Boil 1mol / L nitric acid solution for 45 minutes, then filter the mixture with suction, rinse with distilled water, and dry; set aside.

[0030] (2) Preparation of modified bentonite: Take 5g of sodium bentonite in 20mL of distilled water, adjust the pH to 7.5, add 40mL of a solution containing 5.5mmol of CTAB, react at 80°C for 2h, cool to...

Embodiment 2

[0034] Embodiment 2: As described in Embodiment 1, the difference is the consumption of wheat stalks:

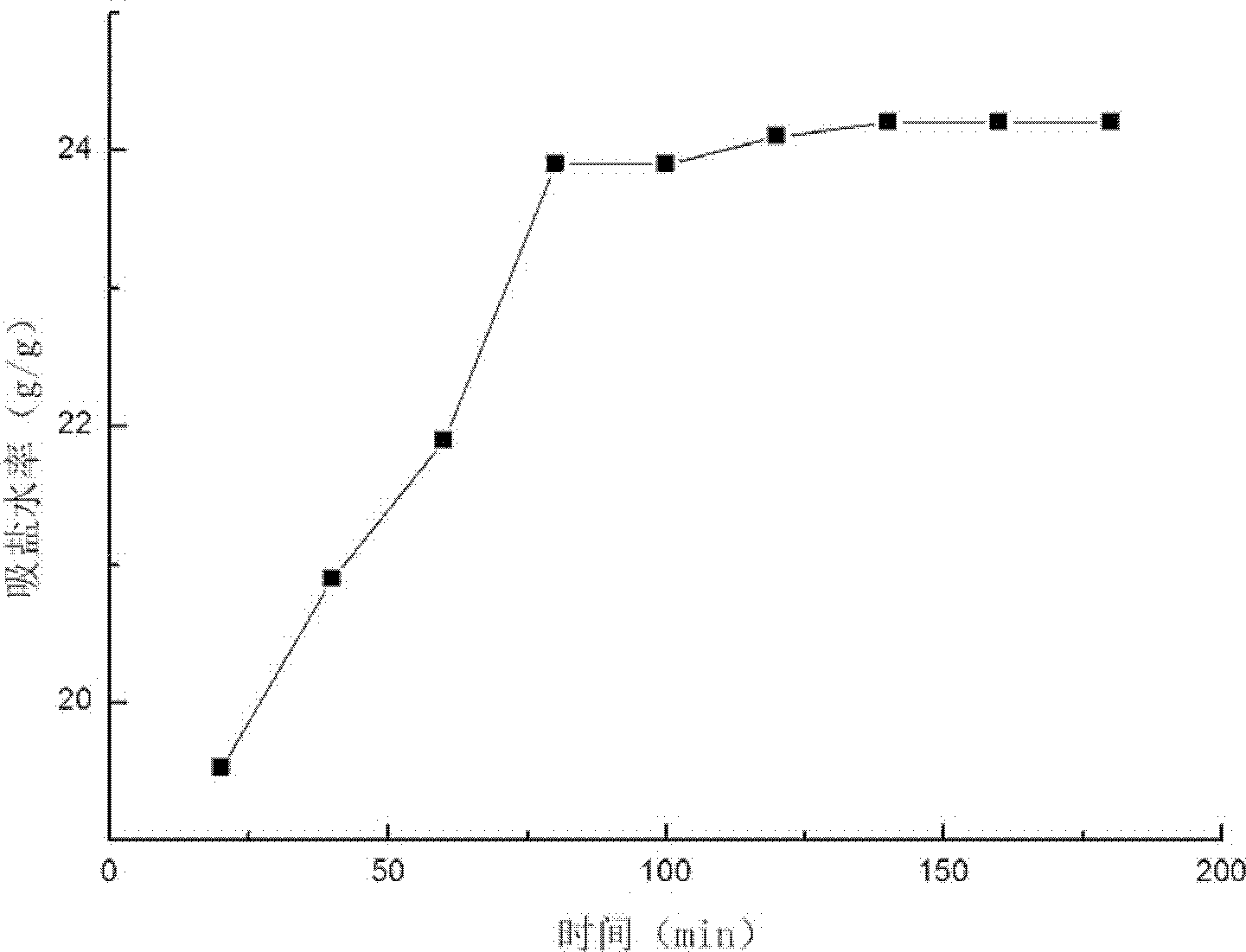

[0035] Take 1.20 g of pretreated wheat straw and 0.12 g of modified bentonite in a three-necked round-bottomed flask, and the rest of the operations are the same as in Example 1. The maximum water absorption rate of the obtained composite superabsorbent resin can reach 168.8g / g, and the salt water absorption rate can reach 22.2g / g.

Embodiment 3

[0036] Embodiment 3: as described in embodiment 1, difference is the consumption of organic bentonite:

[0037] Take 1.00 g of pretreated wheat straw and 0.09 g of modified bentonite in a three-necked round-bottomed flask, and the rest of the operations are the same as in Example 1. The maximum water absorption rate of the obtained composite superabsorbent resin can reach 188.5g / g, and the salt water absorption rate can reach 23.7g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com