Aliphatic-aromatic copolyester and PLA (Poly Lactic Acid) block copolymer and production method and application thereof and composition containing block copolymer

A technology of block copolymer and production method, applied in the field of polymer materials, can solve the problems of waste plastics, incompatibility hindering material performance, white pollution, etc., and achieve good strength, broad ecological and economic benefits, The effect of good toughness and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

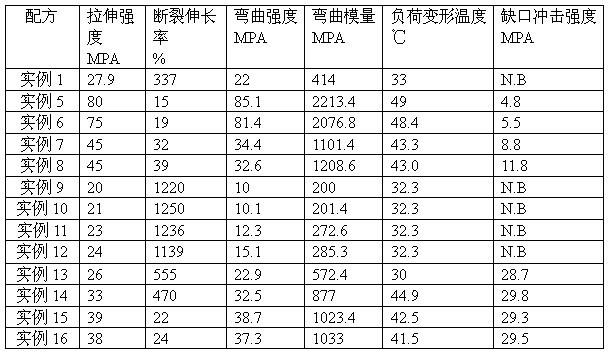

Examples

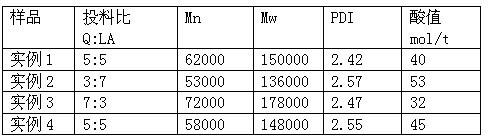

Embodiment 1

[0028] Example 1: Put 5kg of dry aliphatic-aromatic copolyester Q in a reactor that has been dried and replaced with nitrogen, heat up to 100 degrees, adjust the stirring speed to 20rpm, and wait until the aliphatic-aromatic copolyester Q is completely After melting, 5 kg of lactide was added and replaced with nitrogen 3 times. After continuing to stir for 30 minutes, add the catalyst stannous octoate of 0.5% of the total weight of the mixture, and react for 24 hours. After the reaction is finished, add a phosphoric acid stabilizer, continue to stir and react for 30 minutes, and then vacuumize and devolatilize. The block copolymer PLA-Q-PLA was obtained.

[0029] The catalyst in embodiment one can be at least one or a mixture of organic alkaline earth metal compounds, organic transition metal compounds, rare earth organic compounds, aluminum, germanium, tin, and antimony organic compounds, specifically tin octoate, stannous octoate, and ethyl octoate. One or more mixtures of...

Embodiment 2

[0030] Example 2: Put 3kg of dried aliphatic-aromatic copolyester Q into a reactor that has been dried and replaced with nitrogen, heat up to 250 degrees, adjust the stirring speed to 20rpm, and wait until the aliphatic-aromatic copolyester Q is completely After melting, 7 kg of lactide was added and replaced with nitrogen three times. After continuing to stir for 30 minutes, add 0.01% stannous octoate by the total weight of the mixture, and react for 3 hours. After the reaction is finished, add a phosphoric acid stabilizer, continue to stir and react for 30 minutes, and then vacuumize and devolatilize. The block copolymer PLA-Q-PLA was obtained.

Embodiment 3

[0031] Example 3: Put 7kg of dried aliphatic-aromatic copolyester Q into a reaction kettle that has been dried and replaced with nitrogen, raise the temperature to 200 degrees, adjust the stirring speed to 20rpm, and wait until the aliphatic-aromatic copolyester Q is completely After melting, 3 kg of lactide was added and replaced with nitrogen three times. After continuing to stir for 30 minutes, 5% of the total weight of the mixture was added with diethylzinc and reacted for 12 hours. After the reaction is finished, add a phosphoric acid stabilizer, continue to stir and react for 30 minutes, and then vacuumize and devolatilize. The block copolymer PLA-Q-PLA was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com