Preparation of novel polyphosphazene alkaline membrane

A polyphosphazene and alkaline membrane technology, which is applied to fuel cell parts, structural parts, battery pack parts, etc., can solve the problems of slow electrode kinetic reaction, hindering the industrialization process, and high cost of fuel cells, achieving The effect of good ion conductivity, good thermochemical stability and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

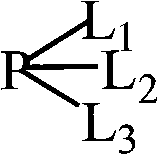

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Poly(p-methylphenoxyphosphazene) Alkaline Membrane

[0043] 1) Preparation of quaternary phosphonium poly-p-methylphenoxyphosphazene film

[0044] To 0.5g of brominated poly-p-methylphenoxyphosphazene in 20mL of tetrahydrofuran solution, add dropwise excess triphenylphosphine in 20mL of tetrahydrofuran solution, and stir at 10-90°C for 1-7h to obtain a light yellow precipitate, which is the quaternary Phosphonium poly(p-methylphenoxyphosphazene). Dissolve it in 5mL of N,N-dimethylformamide solution, ultrasonically dissolve and defoam, then cast at 20-120°C for 12-60h to form a film.

[0045] 2) Preparation of poly-p-methylphenoxyphosphazene basic membrane

[0046] The above-mentioned quaternary phosphonium poly-p-methylphenoxyphosphazene film was mixed in 1mol L -1 Soak in KOH solution for 48 hours for ion exchange, and then wash with deionized water to obtain a light yellow film, which is the poly-p-methylphenoxyphosphazene basic film.

Embodiment 2

[0048] Preparation of Poly(p-methylphenoxyphosphazene) Crosslinked Alkaline Membrane

[0049] 1) Preparation of quaternary phosphonium poly(p-methylphenoxyphosphazene) crosslinked membrane

[0050] To 0.5g of brominated poly-p-methylphenoxyphosphazene in 20mL of tetrahydrofuran solution, drop a certain mass ratio of triphenylphosphine and polyethylene glycol (200) sodium in 30mL of tetrahydrofuran solution, at 10~90℃ , Stirring for 1-7h, a light yellow precipitate was obtained, which was cross-linked quaternary phosphonium poly-p-methylphenoxyphosphazene. Dissolve it in 5mL of N,N-dimethylformamide solution, ultrasonically dissolve and defoam, then cast at 20-120°C for 12-60h to form a film.

[0051] 2) Preparation of poly-p-methylphenoxyphosphazene crosslinked alkaline membrane

[0052] The above-mentioned quaternary phosphonium poly-p-methylphenoxyphosphazene cross-linked film was mixed in 1mol L -1 Soak in KOH solution for 48 hours for ion exchange, and then wash with de...

Embodiment 3

[0054] Preparation of poly-p-methylphenoxyphosphazene blend alkaline membrane

[0055] 1) Preparation of quaternary phosphonium poly(p-methylphenoxyphosphazene) blend film

[0056] To 0.5g of brominated poly-p-methylphenoxyphosphazene in 20mL of tetrahydrofuran solution, add dropwise excess triphenylphosphine in 20mL of tetrahydrofuran solution, and stir at 10-90°C for 1-7h to obtain a light yellow precipitate, which is the quaternary Phosphonium poly(p-methylphenoxyphosphazene). Dissolve it in 5mL of N,N-dimethylformamide solution, add a certain amount of polyethylene glycol (200) dropwise, ultrasonically dissolve and defoam, then cast at 20-120°C for 12-60h to form a film.

[0057] 2) Preparation of poly-p-methylphenoxyphosphazene blended alkaline membrane

[0058] The above-mentioned quaternary phosphonium poly-p-methylphenoxyphosphazene blend film was mixed in 1mol L -1 Soak in KOH solution for 48 hours for ion exchange, and then wash with deionized water to obtain a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com