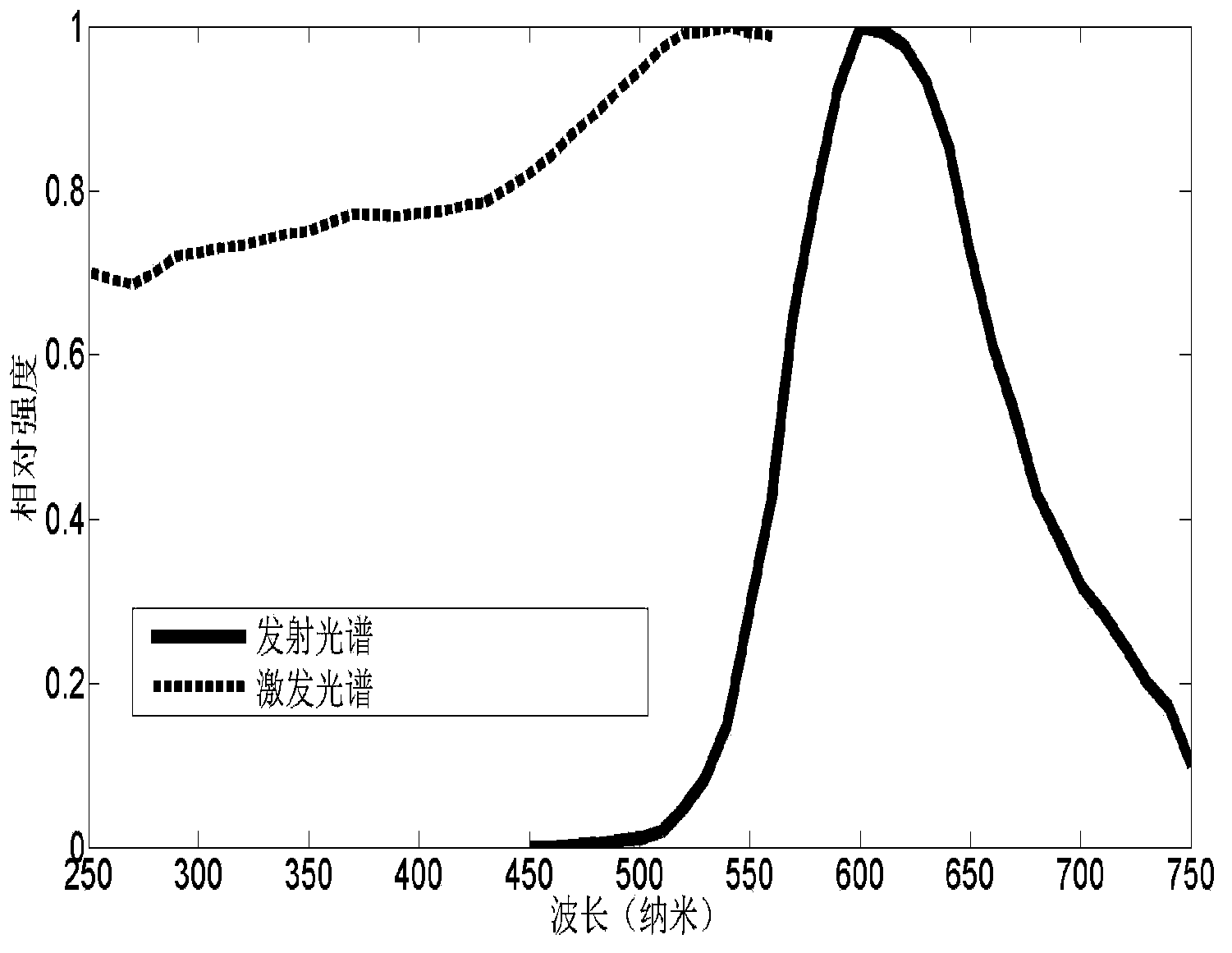

Silica-coated orange-red phosphor and preparation method thereof

A silicon dioxide and phosphor technology, applied in the field of orange-red phosphor and its preparation, can solve problems such as easy failure, and achieve the effects of improving color rendering, enhancing stability and reducing synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

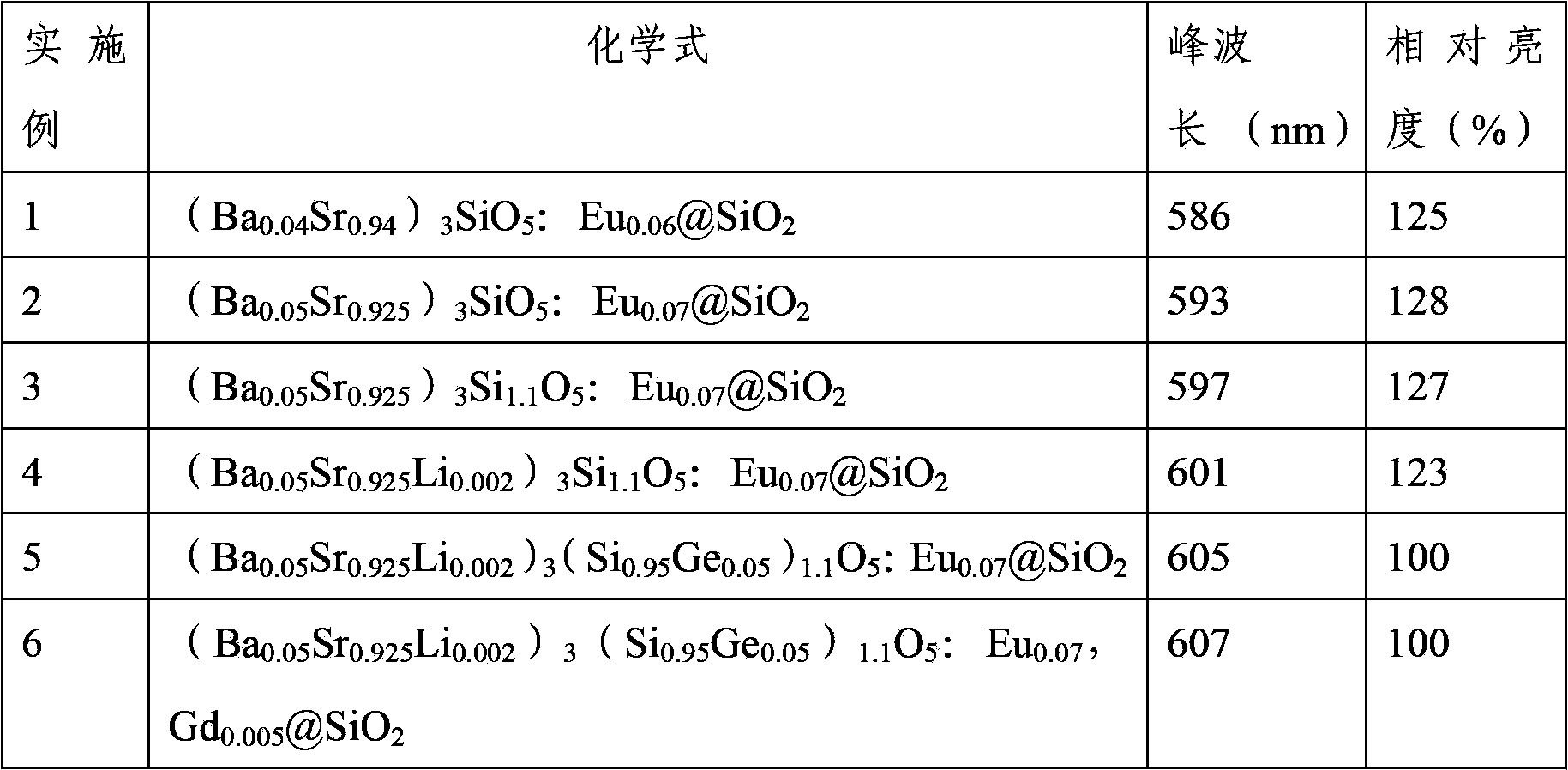

Embodiment 1

[0039] The chemical structural formula (Ba 0.04 Sr 0.94 ) 3 SiO 5 : Eu 0.06 SiO 2 , weigh high-purity SrCO 3 (41.63 g), BaCO 3 (2.37 g), SiO 2 (6.01 g), EuF 3 (1.25 g), and the reaction flux CaF 2(0.04 grams). The above mixture was put into a high-energy ball mill and pulverized and mixed for 40 minutes. After sieving, the mixed raw materials were put into a high-purity alumina crucible, and in a reducing atmosphere (5% H 2 / N 2 gas), keep it at 1000 degrees for 2 hours, then raise the temperature to 1250 degrees for 5 hours. Cool naturally to room temperature, take it out, and carry out post-treatment after sieving to remove superfine powder (<2 μm), and obtain the uncoated phosphor material of the present invention.

[0040] The uncoated fluorescent powder prepared above was evenly dispersed in anhydrous ethylene glycol to prepare a fluorescent powder suspension with a concentration of 5%. Add nano-SiO to this suspension 2 , the SiO used 2 The dosage is 2.5% o...

Embodiment 2

[0042] According to the chemical structural formula (Ba 0.05 Sr 0.925 ) 3 SiO 5 : Eu 0.07 SiO 2 , weigh high-purity SrCO 3 (40.97 g), BaCO 3 (2.96 g), SiO 2 (6.01 g), EuF 3 (1.46 g), and the reaction flux CaF 2 (0.33 grams). The above mixture was put into a high-energy ball mill and pulverized and mixed for 40 minutes. After sieving, the mixed raw materials were put into a high-purity alumina crucible, and in a reducing atmosphere (5% H 2 / N 2 Gas), keep warm at 1300 degrees for 2 hours, then raise the temperature to 1250 degrees and keep warm for 5 hours. Cool naturally to room temperature, take it out, and carry out post-treatment after sieving to remove superfine powder (<2 μm), and obtain the uncoated phosphor material of the present invention.

[0043] The uncoated fluorescent powder prepared above was evenly dispersed in anhydrous ethylene glycol to prepare a fluorescent powder suspension with a concentration of 5%. Add nano-SiO to this suspension 2 , the S...

Embodiment 3

[0045] According to the chemical structural formula (Ba 0.05 Sr 0.925 ) 3 Si 1.1 o 5 : Eu 0.07 SiO 2 , weigh high-purity SrCO 3 (40.97 g), BaCO 3 (2.96 g), SiO 2 (6.61 g), EuF 3 (1.46 g), and the reaction flux CaF 2 (0.33 grams). The above mixture was put into a high-energy ball mill and pulverized and mixed for 40 minutes. After sieving, the mixed raw materials were put into a high-purity alumina crucible, and in a reducing atmosphere (5% H 2 / N 2 Gas), keep at 1000 degrees for 12 hours, then raise the temperature to 1250 degrees for 5 hours. Cool naturally to room temperature, take it out, and carry out post-treatment after sieving to remove superfine powder (<2 μm), and obtain the uncoated phosphor material of the present invention.

[0046] The uncoated fluorescent powder prepared above was evenly dispersed in anhydrous ethylene glycol to prepare a fluorescent powder suspension with a concentration of 5%. Add nano-SiO to this suspension 2 , the SiO used 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com