Cleaning agent for filth on surface of room temperature vulcaniza-tion (RTV) coating insulator

A technology for insulators and cleaning agents, applied in the field of cleaning agents, can solve the problems of large differences in coating strength and adhesion, strong corrosion damage, and poor decontamination ability, so as to achieve thorough decontamination removal, improve cleaning effect, and prevent redeposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

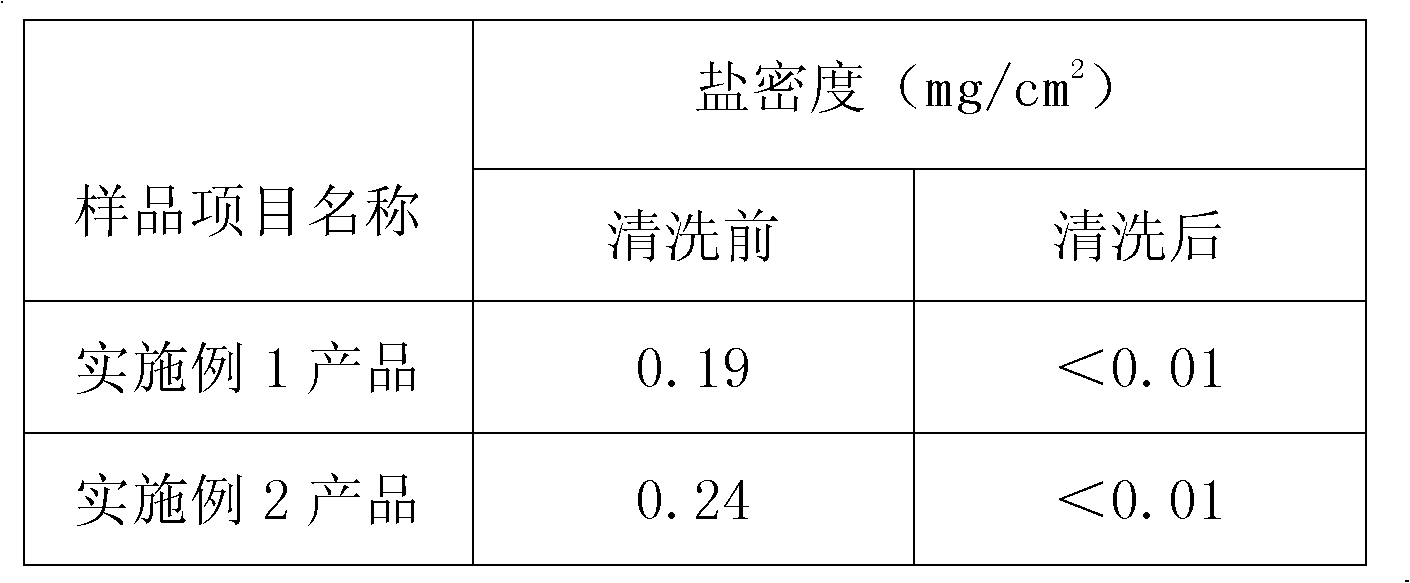

Examples

Embodiment 1

[0018] Back up the ingredients by weight as follows:

[0019] Disodium edetate 1kg,

[0020] Sodium glycolate 49kg,

[0021] Sodium polyacrylate 10kg,

[0022] Disodium hydroxyethylidene diphosphonate 50kg,

[0023] Alkylphenol polyoxyethylene ether 20kg,

[0024] Fatty alcohol polyoxyethylene ether 20kg,

[0025] 9850kg of water.

Embodiment 2

[0027] Back up the ingredients by weight as follows:

[0029] Sodium Gluconate 1kg

[0030] Sodium polyacrylate 100kg,

[0031] Disodium hydroxyethylidene diphosphonate 100kg,

[0032] Alkylphenol polyoxyethylene ether 100kg,

[0033] Fatty alcohol polyoxyethylene ether 100kg,

[0034] 8600kg of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com