Method and system for preparing high purity gas by rectification method

A technology of high-purity gas and rectification method, which is applied in the field of high-purity gas preparation by rectification method, can solve the problems of large equipment and energy consumption, poor operating pressure, poor flow adjustment flexibility, and limited system adjustment, and achieve energy saving, The effect of less public engineering requirements and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

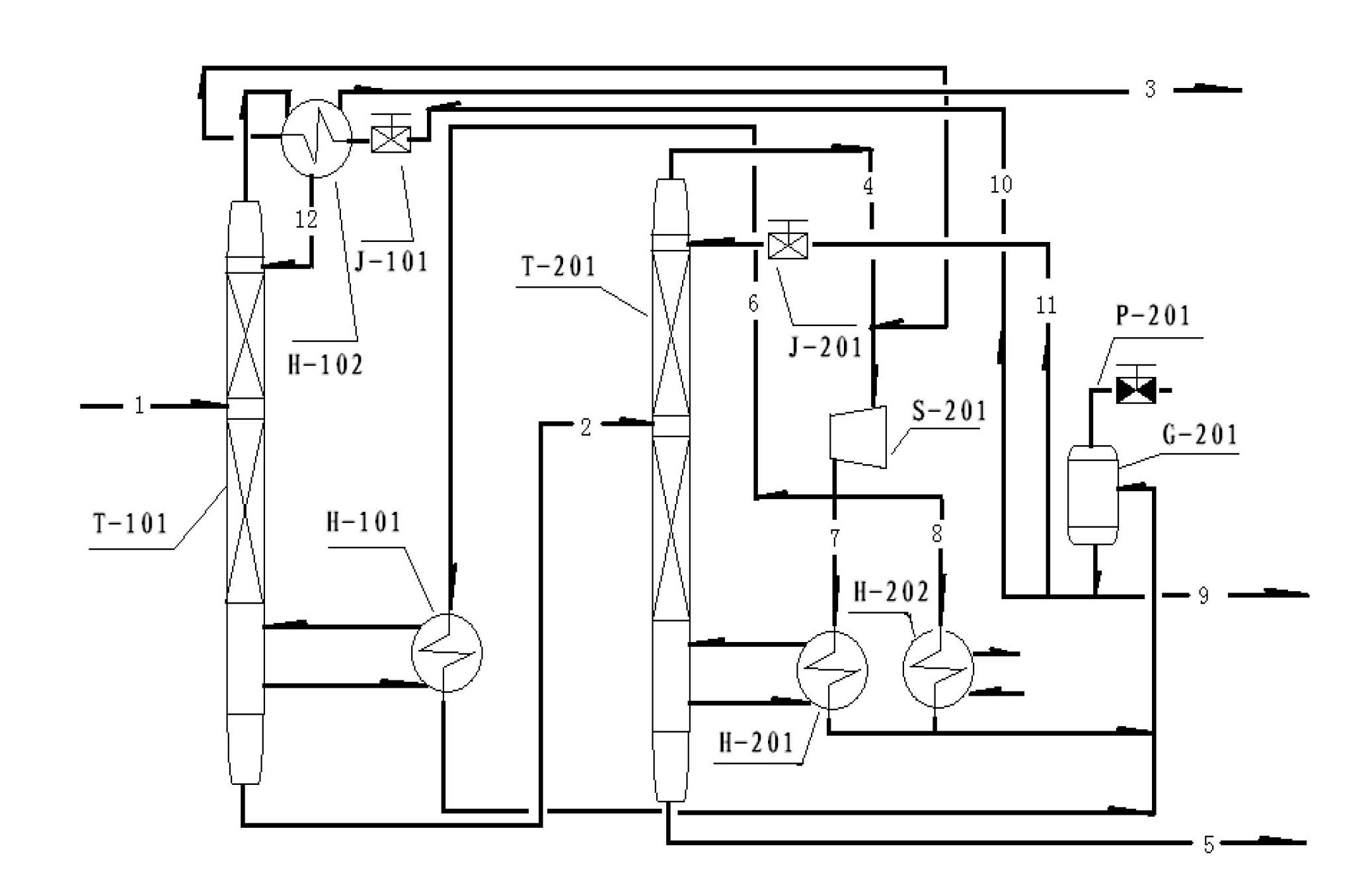

Image

Examples

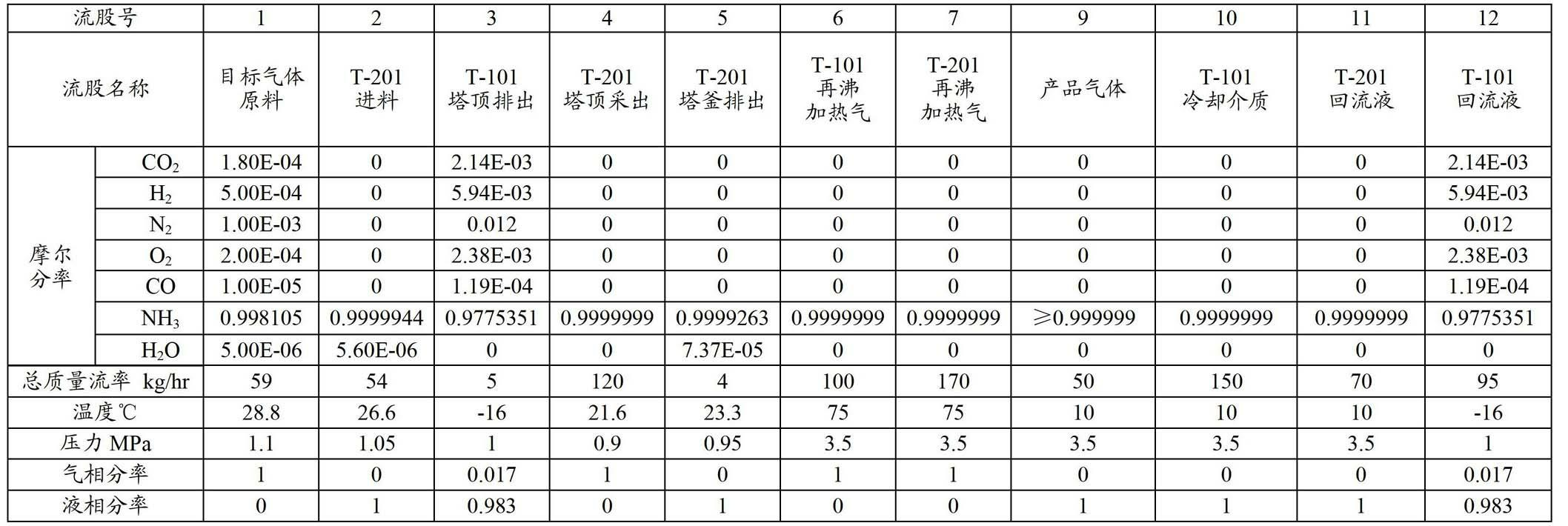

Embodiment 1

[0045] The preparation of embodiment 1 high-purity ammonia

[0046] Ammonia gas usually exists in the form of liquid ammonia. The light component impurities in liquid ammonia include hydrogen, nitrogen, oxygen, carbon monoxide, carbon dioxide, etc., and the heavy component impurities generally include water, heavy hydrocarbons, oil pollution, etc. The traditional liquid ammonia purification method is to vaporize liquid ammonia into gas, first remove the heavy component impurities such as water and oil through activated carbon adsorbent, and then remove hydrogen, nitrogen, oxygen, carbon monoxide, carbon dioxide and other light substances through the rectification tower. Component impurities are finally pressurized and bottled by a compressor. This method is complicated to operate, and the energy consumption of rectification purification is very high, and it is difficult to achieve the purity of 7.0N (99.99999%) gas ammonia required by the electronics industry.

[0047] Throu...

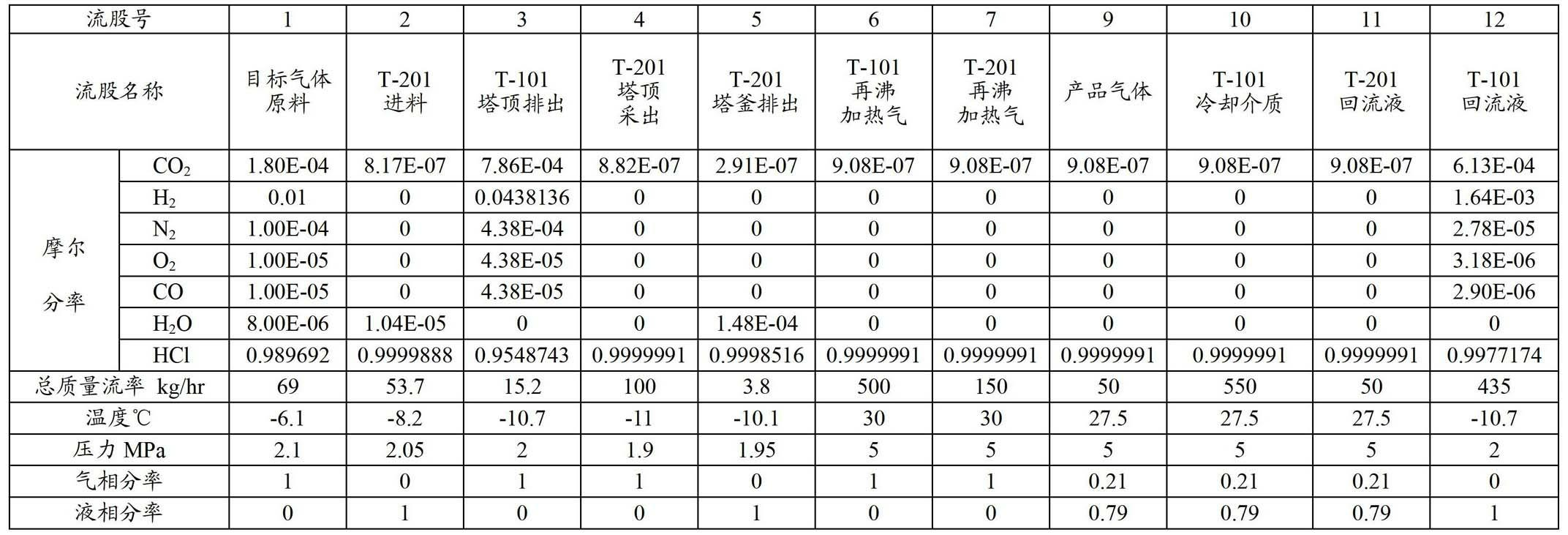

Embodiment 2

[0055] The preparation of embodiment 2 high-purity hydrogen chloride

[0056] Hydrogen chloride gas prepared by conventional methods generally contains carbon dioxide impurities, and the removal of carbon dioxide in hydrogen chloride gas is a recognized problem in the field, and there is currently no effective solution. Conventional adsorption, reaction and rectification methods for removing carbon dioxide are not suitable for removing carbon dioxide from anhydrous hydrogen chloride. For the adsorption method, due to the large molecular volume of carbon dioxide, it is difficult to enter the micropores of the adsorbent and be adsorbed in large quantities. At present, no adsorbent that can effectively adsorb carbon dioxide but not hydrogen chloride has been found; while the conventional reaction method for removing carbon dioxide, that is, CO 2 +3H 2 =CH 4 +2H 2 O, the water generated by this method will combine with hydrogen chloride gas to form hydrochloric acid, which will...

Embodiment 3

[0067] The preparation of embodiment 3 high-purity chlorine

[0068] Chlorine usually contains impurities such as hydrogen, oxygen, nitrogen, carbon monoxide, and carbon dioxide. Most of the traditional chlorine gas purification methods use the adsorption method. Since the purification depth of the product depends on the ability and activation degree of the adsorbent, not only the selection of the adsorbent is difficult, but also the purification effect is not good, the operation is complicated, the energy consumption is high, and the cost is high.

[0069] Applying the method and system for purifying gas by the rectification method of the present invention can easily remove impurities in the chlorine gas, and obtain high-purity chlorine gas products of 5.0N or higher for the electronic industry. Similar to the hydrogen chloride gas in Example 2, the chlorine gas containing water is also corrosive to a certain extent. Therefore, in this embodiment, the moisture of the chlorine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com