Tail gas utilization method and tail gas utilization system of rotary lime kiln

A lime rotary kiln and calcium carbide furnace exhaust gas technology, which is applied in the directions of dry gas arrangement, preheating cost, waste heat treatment, etc., can solve the problems of hidden safety hazards, high damage rate, and easy breakage of semi-coke, and achieve environmental protection. Emission reduction, semi-coke Reduced breakage and efficient use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

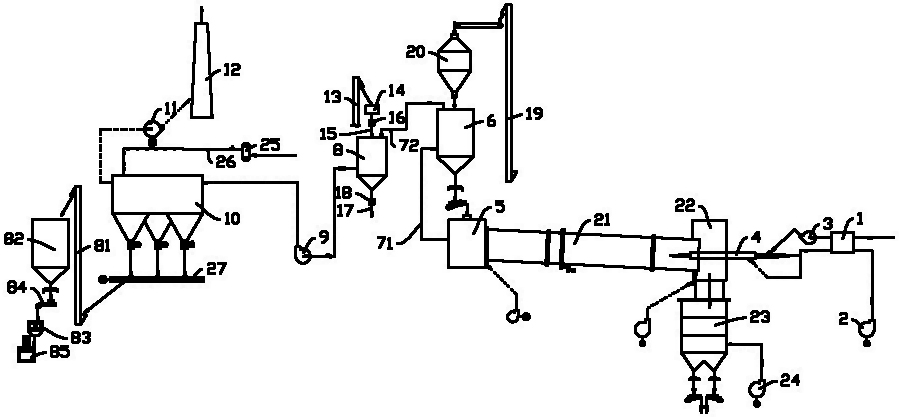

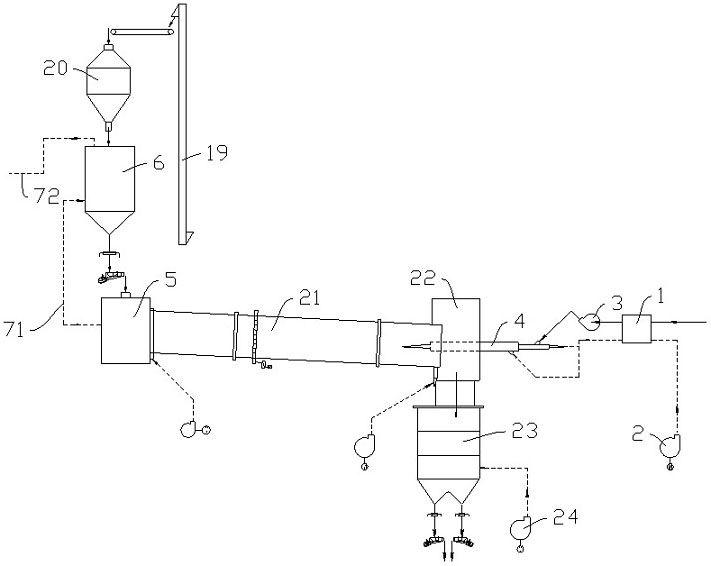

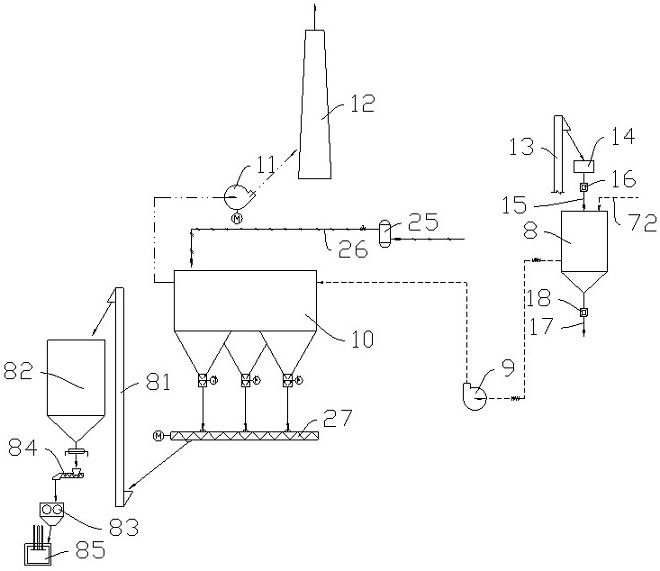

[0029] see Figure 1-3 In the comprehensive utilization system of calcium carbide furnace exhaust gas and lime rotary kiln exhaust gas shown in the figure, the unpurified high-temperature calcium carbide furnace exhaust gas directly enters the shell side of heat exchanger 1, and blows into the tube side of heat exchange through blower 2 in the heat exchanger After the air is heat-exchanged, the cooled calcium carbide furnace tail gas is pressurized by the gas pressurization conveying fan 3 and sent to the burner 4 of the lime rotary kiln for combustion, and the heated combustion-supporting air coming out of the heat exchanger is also sent to the burner 4 of the lime rotary kiln. into the burner 4 for combustion.

[0030]The lime rotary kiln exhaust gas coming out of the smoke chamber 5 at the tail of the lime rotary kiln enters the preheater 6 from the side lower part of the limestone vertical preheater 6 through the lime rotary kiln exhaust gas discharge pipe 71, and the lime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com