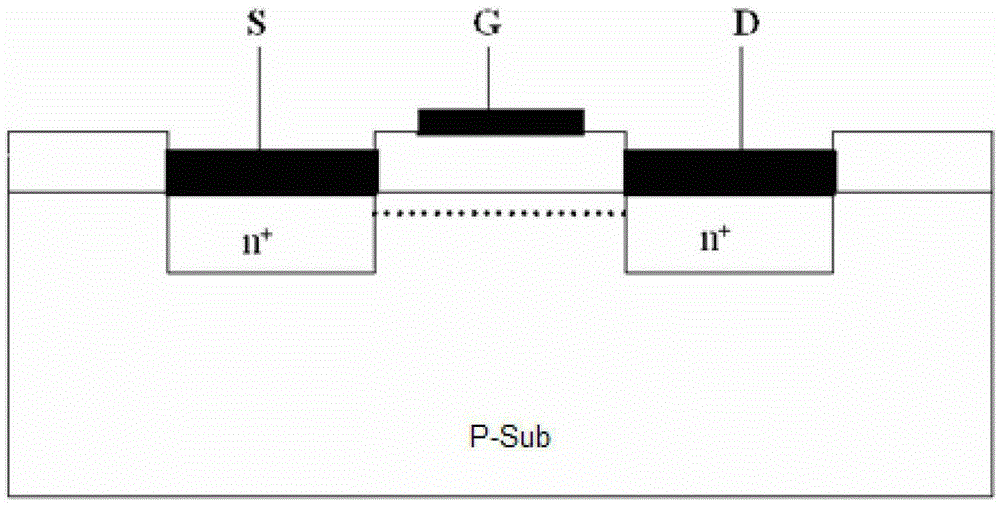

A superconducting field effect transistor, its manufacturing method and application method

A fabrication method and technology for transistors, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as device leakage, transistor performance degradation, and difficulty in further reducing channel length, achieving high speed and improving stability. , the effect of avoiding device failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] like Figure 4~Figure 10 Shown, the present invention provides a kind of manufacturing method of superconducting field effect transistor, and described manufacturing method comprises at least:

[0059] like Figure 4 As shown, step 1) is first performed to provide a semiconductor-on-insulator substrate, including a back substrate 701 , an insulating layer 702 on the back substrate 701 , and a semiconductor thin film of the first doped conductivity type on the insulating layer 702 .

[0060] In the method for manufacturing a superconducting field effect transistor, the semiconductor film is P-type doped or N-type doped Si, Ge, SiGe, SiGeC, or III-V semiconductor material. In this embodiment, the back substrate 701 is Si, and the insulating layer 702 is SiO 2 , the semiconductor film is N-type doped Si.

[0061] like Figure 5 As shown, then proceed to step 2), define a channel region 703 in the semiconductor film, and etch both sides of the channel region 703 to the ...

Embodiment 2

[0074] see Figure 4~Figure 10 , the present embodiment provides a manufacturing method of a superconducting field effect transistor, the basic steps of which are as in embodiment 1, wherein the semiconductor thin film is P-type doped, and the superconductor source 704 and superconductor drain 705 are P Type La-Sr-Cu-O, Y-Ba-Cu-O, Bi-Sr-Ca-Cu-O or Tl-Ba-Sr-Cu-O based superconducting thin films. Of course, in other embodiments, the superconducting thin film can also be any expected superconducting material. The channel region 703 is made of P-type doped Ge material, the shape of the channel region 703 is truncated, and the length is 50nm.

Embodiment 3

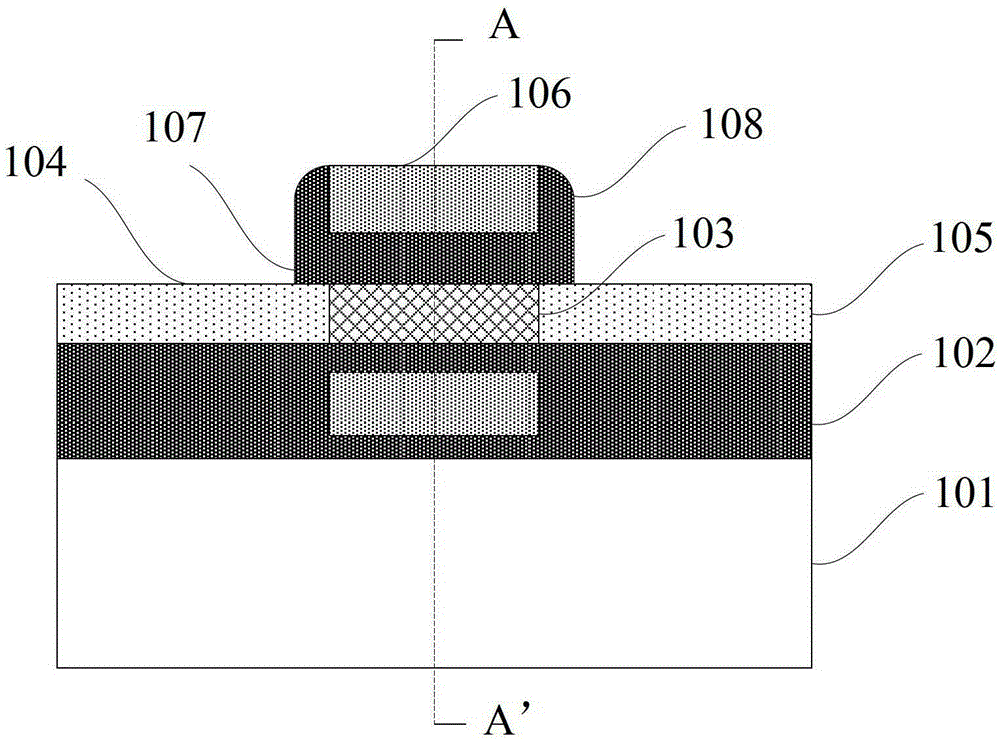

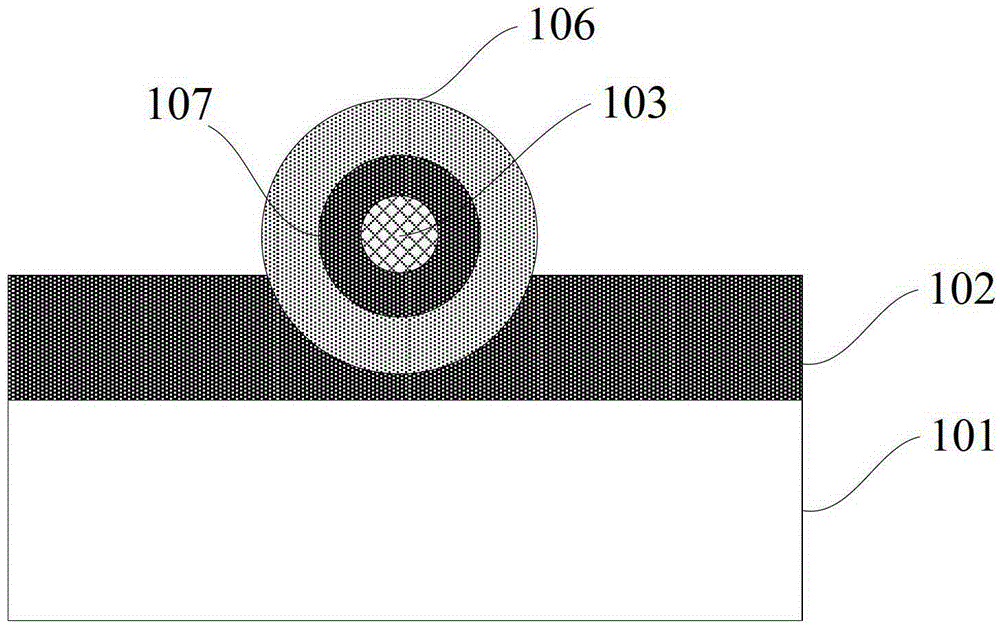

[0076] like Figure 2a~3e As shown, the present invention also provides a superconducting field effect transistor, comprising at least: a semiconductor-on-insulator substrate, a superconductor source 104 formed on the semiconductor-on-insulator substrate, a superconductor drain 105, and a superconductor source located at the superconductor source The channel region 103 between the electrode 104 and the superconductor drain 105, and the gate structure, wherein the channel region 103, the superconductor source 104, and the superconductor drain 105 have the same doping conductivity type.

[0077] The length of the channel region 103 is 10-1000nm. In the present embodiment, the length of the channel region 103 is 100nm, which is connected to the superconductor source and drain to be in a superconducting state, which greatly improves the performance of the device. drive current and response speed.

[0078] The channel region 103 is a column, prism, circular truncated or truncated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com