BiOI/BiOBr multilevel structure composite visible light catalyst, and preparation method and application thereof

A visible light and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low quantum yield, achieve good dispersion, improve performance, and produce stable products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Put 0.45mmolNaI, 0.1g citric acid, and 0.1g cetyltrimethylammonium bromide in 200mL distilled water: ethanol: ethylene glycol in a mixed solvent with a volume ratio of 100:30:70, stir and dissolve into a transparent solution, Then heated to 60°C, and 3mL of 0.15mol / L Bi(NO 3 ) 3 Aqueous solution (0.45mmol), stirred at constant temperature for 1h, 3mL of 0.15mol / L NaBr aqueous solution (0.45mmol) was added dropwise to it, and then stirred at constant temperature for 3h to obtain a suspension solution, cooled to room temperature and centrifuged for 3min to obtain a precipitate, which was used Wash with distilled water and ethanol several times. Then dry at 60°C to prepare BiOI / BiOBr multi-level structure composite visible light catalyst.

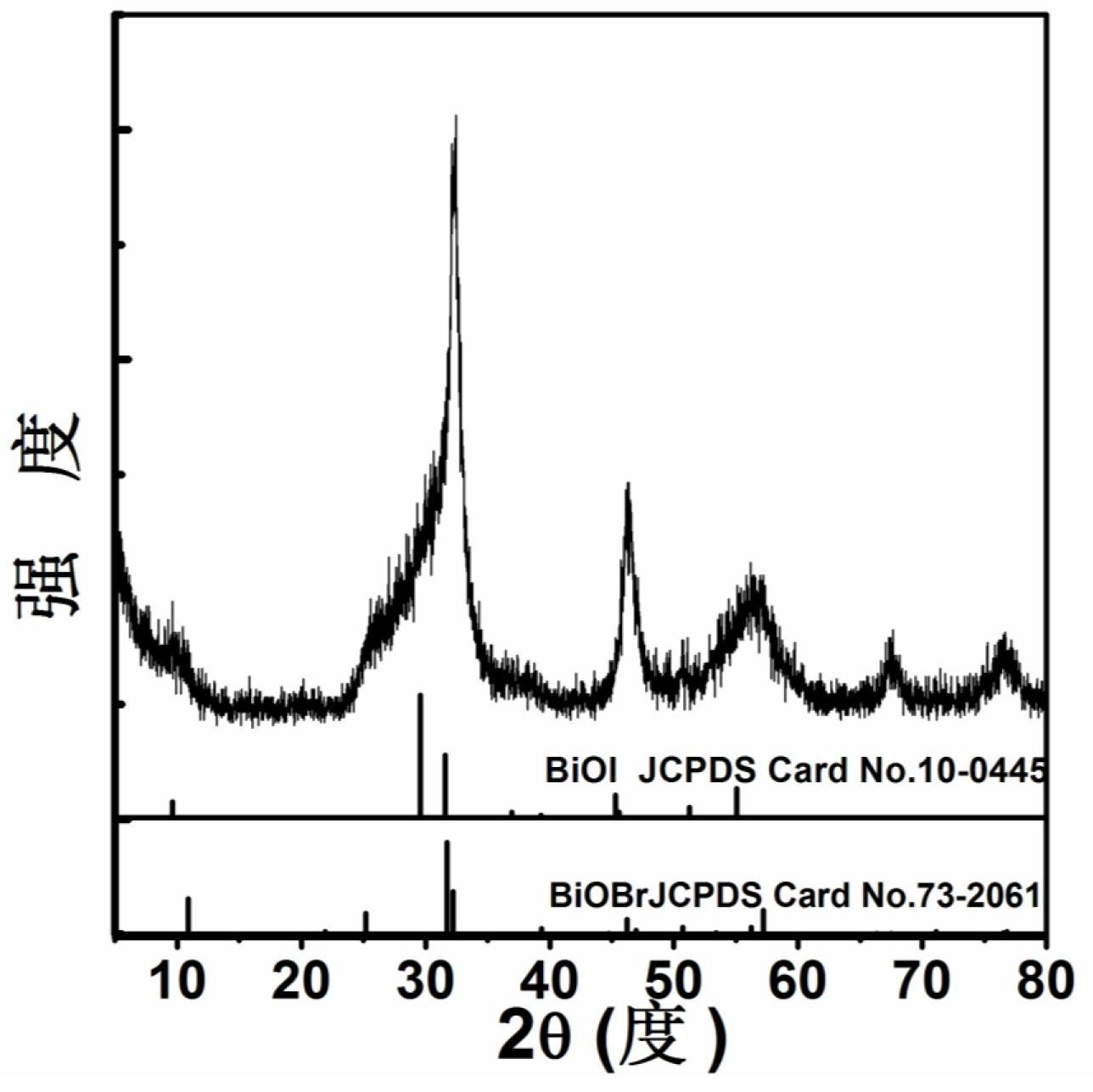

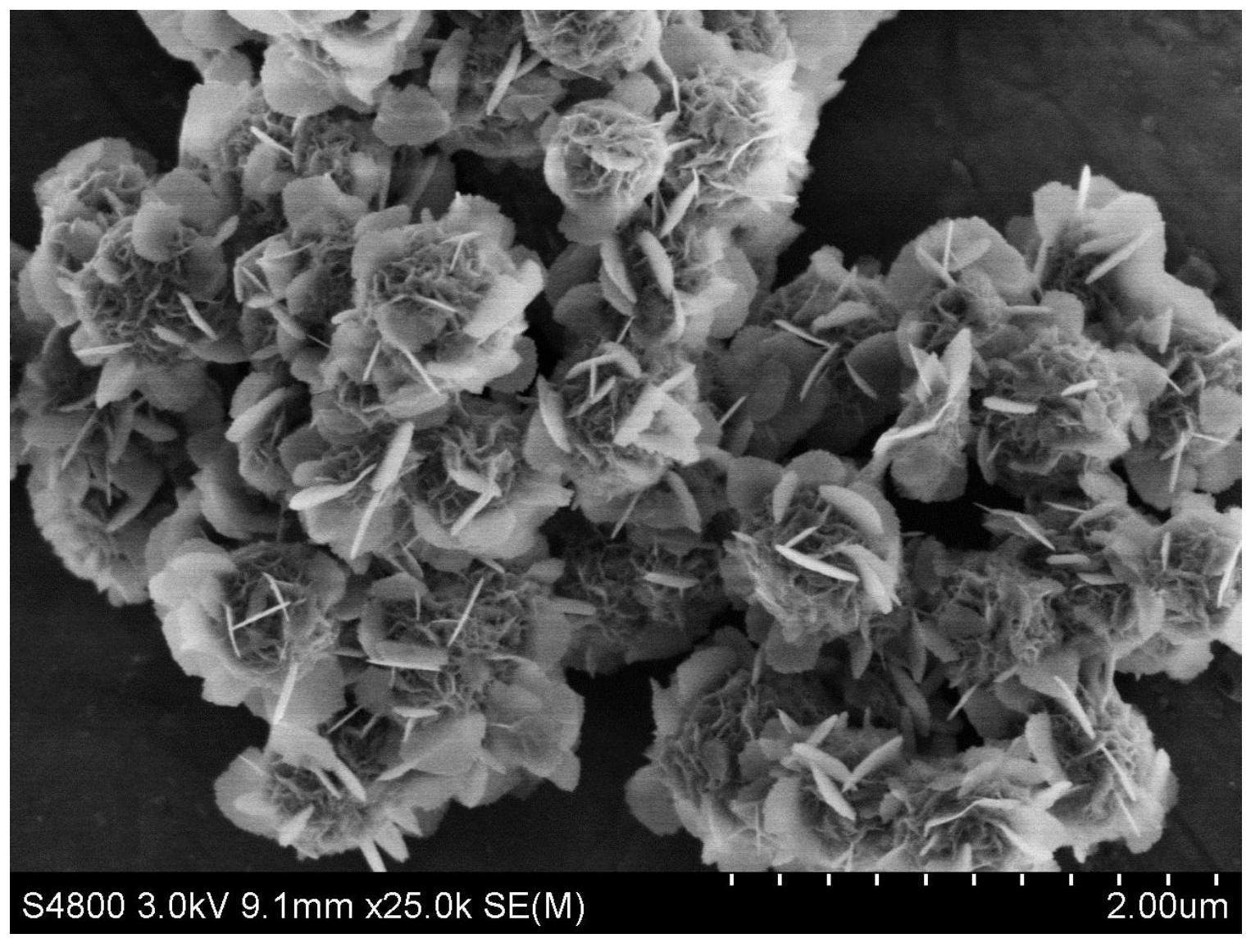

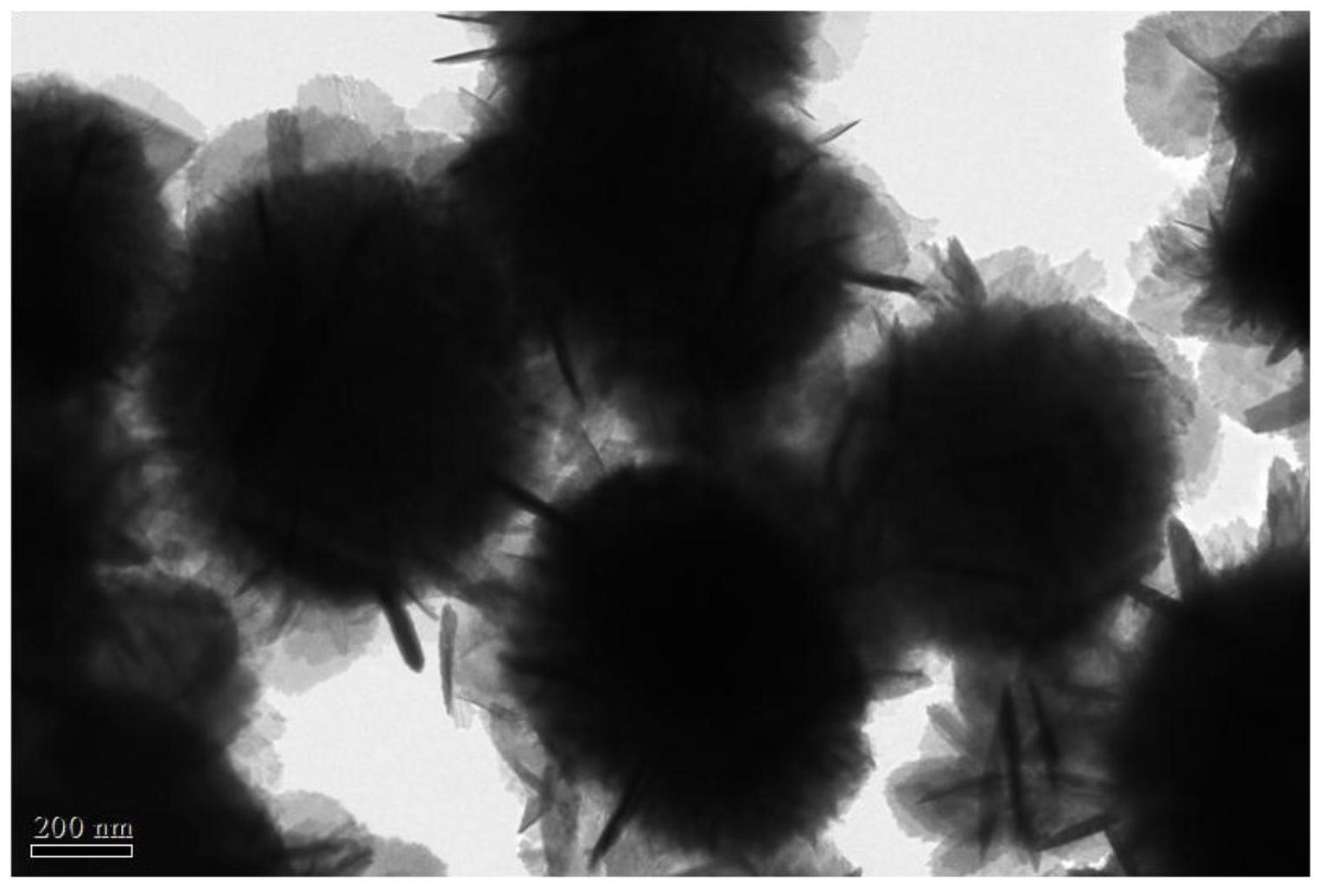

[0030] figure 1 It is the XRD spectrogram of the synthesis of BiOI / BiOBr multi-level structure composite visible light catalyst in Example 1 of the present invention, it can be seen that the diffraction peaks of 2θ=25.26, 32.31, 46.3...

Embodiment 2

[0035] Put 0.45mmolNaI, 0.45mmolNaBr, 0.1g citric acid, and 0.1g cetyltrimethylammonium bromide in a fixed ratio of distilled water: ethanol: ethylene glycol mixed solvent (100:30:70), stir and dissolve into a transparent solution ; and then heated to 60°C, to which 0.45mmol Bi(NO 3 ) 3 The aqueous solution was stirred at constant temperature for 4 hours to obtain a suspension solution, cooled to room temperature and centrifuged for 3 minutes to obtain a precipitate, which was washed with distilled water and ethanol several times. Then dry at 60°C to prepare BiOI / BiOBr multi-level structure composite visible light catalyst.

Embodiment 3

[0037]Put 0.45mmolNaI, 0.1g citric acid, and 0.1g cetyltrimethylammonium bromide in 200mL fixed ratio distilled water: ethanol: ethylene glycol mixed solvent (100:30:70). The transparent solution was heated at 60 °C, and 0.45 mmol Bi(NO 3 ) 3 The aqueous solution was stirred at constant temperature for 4 hours to obtain a suspension solution; the obtained suspension solution was cooled to room temperature and centrifuged for 3 minutes to obtain a precipitate, which was washed with distilled water and ethanol several times. Then dry it at 60°C to prepare BiOI photocatalyst.

[0038] 0.45mmolNaBr was replaced by NaI, and the remaining steps were the same as above to prepare BiOBr photocatalyst. The BiOI / BiOBr composite photocatalyst was prepared by stirring and mixing the obtained BiOI and BiOBr in equimolar ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com