Direct control method for titanium-aluminum-niobium alloy lamellar structure

A technology of direction control and titanium-aluminum-niobium, which is applied in chemical instruments and methods, self-solidification methods, crystal growth, etc., can solve problems such as uneven composition and properties of directionally solidified alloys, complex preparation processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

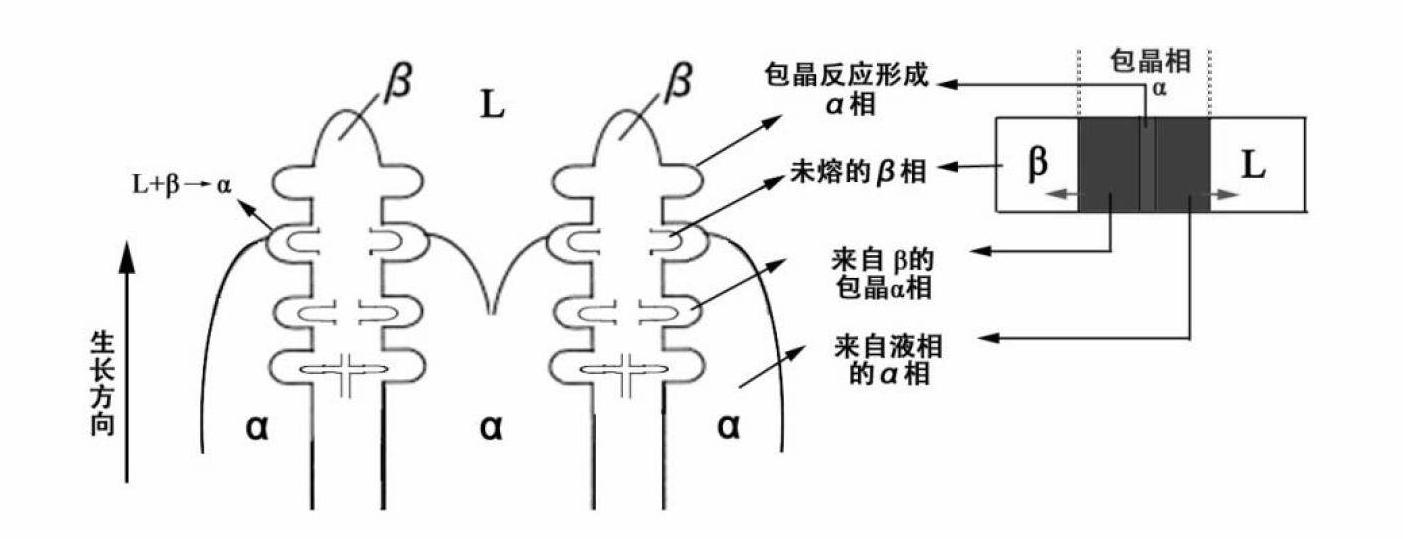

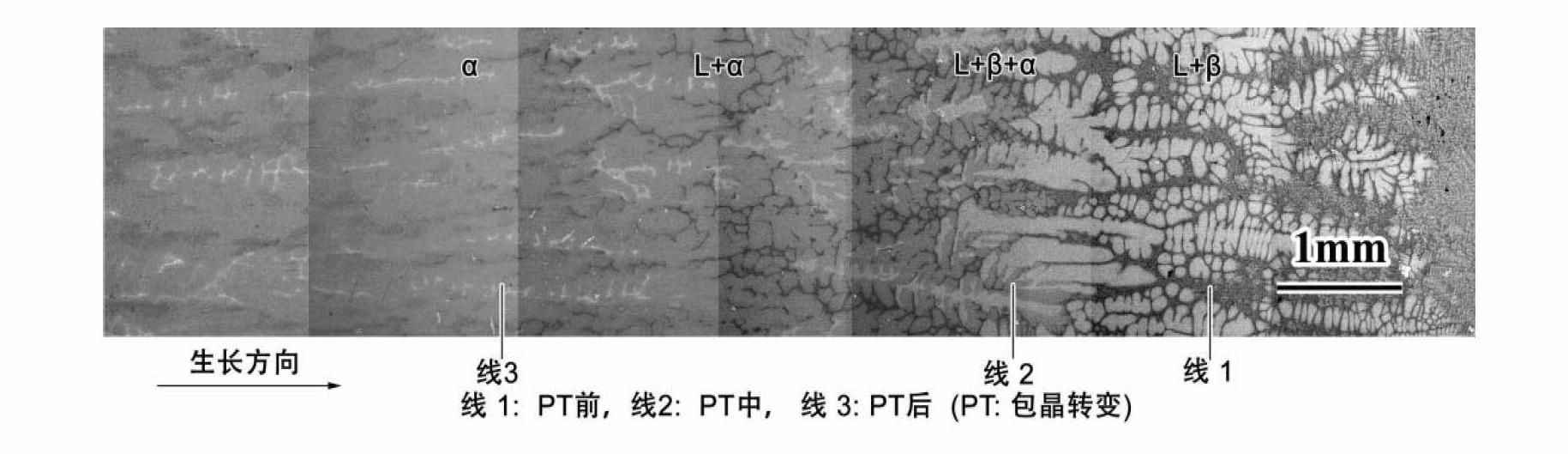

[0032] The research composition is Ti-46Al-5Nb (49Ti-46Al-5Nb) alloy, the experiment adopts the typical Bridgman method, when the vacuum reaches 5x10 -3 After Pa, the protective gas high-purity argon is introduced to make the vacuum degree reach -0.068MPa, and then the electric heating is applied to raise the temperature above the melting point of titanium-aluminum alloy, and the temperature is kept for 8 minutes, and then pulled at a speed of 30μm / s. Under experimental conditions G=5.2×10 3 K / m, when the drawing length is half of the sample length, start the quick quenching device to retain the solid-liquid interface shape at the drawing rate. Then, samples were cut from the directional solidification samples for microstructure observation, and the growth conditions of the first solidified β-phase dendrites, the growth conditions of the peritectic phase in the quenching zone along the growth direction and perpendicular to the direction of directional solidification, and the ...

Embodiment 2

[0035] The titanium-aluminum alloy whose composition is Ti-45Al-8Nb(W, B, Y) (47Ti-45Al-8Nb) is studied. The experiment adopts the typical Bridgman method. When the vacuum degree reaches 5x10 -3 After Pa, the protective gas high-purity argon is introduced to make the vacuum degree reach -0.06MPa, and then the electric heating is applied to raise the temperature above the melting point of titanium-aluminum alloy. Under experimental conditions G=3.8×10 3 K / m, when the drawing length is half of the sample length, start the quick quenching device to retain the solid-liquid interface shape at the drawing rate. After the system was cooled to room temperature, the sample was taken out and polished on multiple surfaces, and the sample was cut from the directionally solidified sample for microstructure observation. The growth conditions perpendicular to the direction of directional solidification, the grain size and crystal orientation of the peritectic phase transformation process w...

Embodiment 3

[0037] The titanium-aluminum alloy whose composition is Ti-46Al-2Nb (52Ti-46Al-2Nb) is studied. The experiment adopts the typical Bridgman method. When the vacuum degree reaches 5x10 -3 After Pa, the protective gas high-purity argon is introduced to make the vacuum degree reach -0.05MPa, and then the electric heating is applied to raise the temperature above the melting point of titanium-aluminum alloy. Under experimental conditions G=7.7×10 3 K / m, when the drawing length is 45mm, start the quick quenching device to retain the solid-liquid interface morphology at the drawing rate. After the system was cooled to room temperature, the sample was taken out and polished on multiple surfaces, and the sample was cut from the directionally solidified sample for microstructure observation. The growth conditions perpendicular to the direction of directional solidification, the grain size and crystal orientation of the peritectic phase transition process were analyzed, and it was foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com