Thermal positive-type planographic original printing plate and method of making planographic printing plate

A technology of lithographic printing plate and original plate, applied in lithographic printing equipment, printing surface preparation, printing, etc., can solve problems such as damage, poor durability, and poor chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (11) The method for producing a lithographic printing plate described in the above item (10), wherein the alkaline aqueous solution contains an anionic surfactant or a nonionic surfactant.

[0034] Hereinafter, the present invention will be described in detail.

[0035]

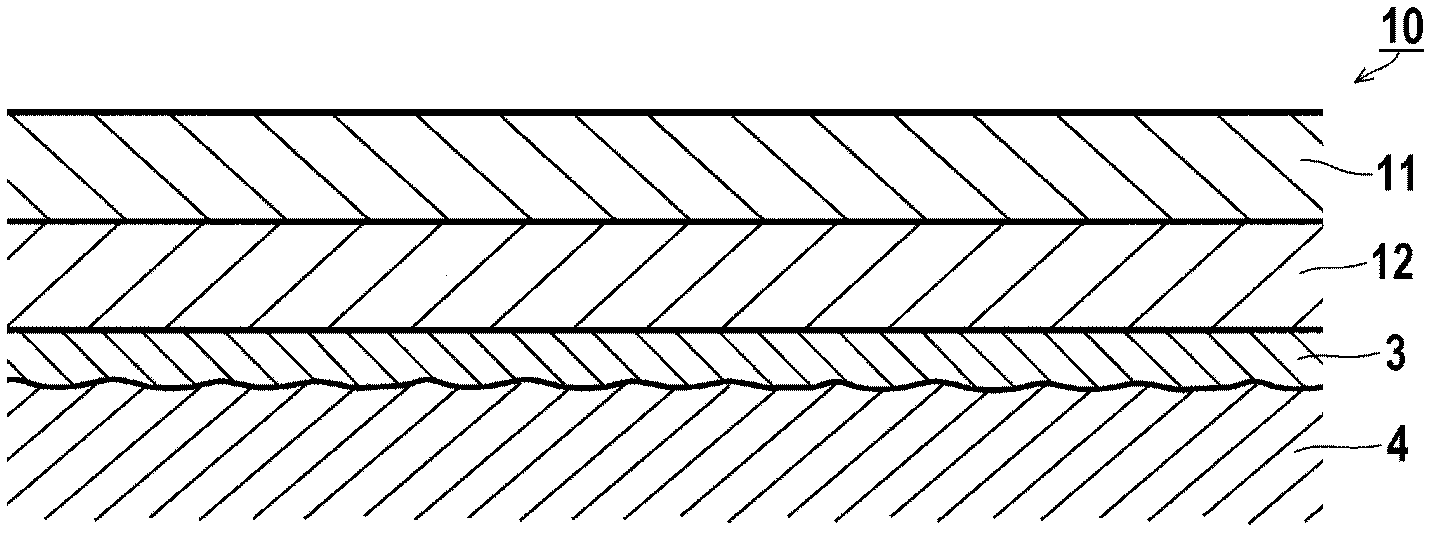

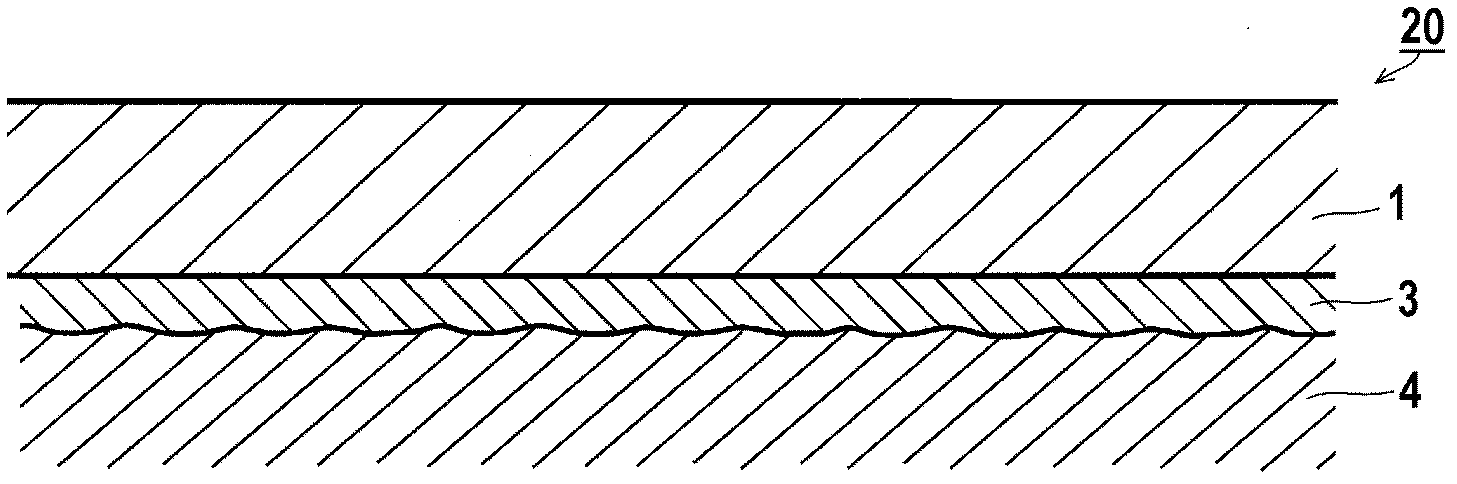

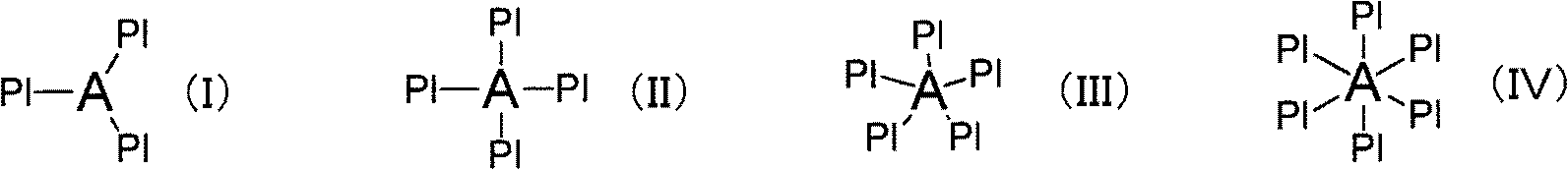

[0036] The lithographic printing plate precursor of the present invention contains (A) a star polymer in which at least 3 polymer chains are bound to atomic groups serving as nuclei and branched radially in at least one recording layer of an arbitrary number of layers provided on a support thereof, (B) Alkali-soluble resin and (C) infrared absorber. Herein, in the case where the recording layer has a configuration of two or more layers, each of the above-mentioned components (A) to (C) may be contained in the same layer, or contained in separate layers middle. The layer construction may be a single layer construction (see figure 2 ; the image-recording layer 1 is disposed on the carrier 4 with th...

Embodiment 2 and 4 *2 Embodiment 3

[0107] *1: Examples 2 and 4 below *2 Example 3 below

[0108]

[0109] In the case of a layered structure, the lower layer preferably contains the infrared absorber (C) described above. The lower layer may contain other components, if necessary, as long as they do not impair the effectiveness of the present invention. Examples of other components include (A) a star polymer, and (B) an alkali-soluble resin having a structure different from that of a novolac resin (this resin is referred to as "other alkali-soluble resin").

[0110] (Other Alkali Soluble Resins)

[0111] In the present invention, the term "alkali-soluble" means that the resin is soluble in an alkaline solution having a pH of 8.5 to 13.5 by the treatment of a standard development time. The other alkali-soluble resin used in the lower layer is not particularly limited, as long as the resin has a tendency to be dissolved when contacted with an alkaline developer. The resin preferably has acidic functional grou...

Embodiment 1

[0257] (Example 1, Comparative Example 1)··Printing plate precursor having a single recording layer

[0258]

[0259] The surface of the JIS A1050 aluminum plate was grained by rotating a nylon brush using a pumice-water suspension as an abrasive. Here, the surface roughness (center line average roughness) was 0.5 μm. After rinsing with water, the aluminum plate was immersed in a 10% aqueous solution of sodium hydroxide that had been heated to 70°C and etched so that the amount of dissolved aluminum was 6 g / m 3 . After rinsing with water, the board was immersed in a 30% nitric acid aqueous solution for 1 minute for neutralization, and was sufficiently rinsed with water. Afterwards, the aluminum plate was subjected to electrolytic roughening in 0.7% nitric acid aqueous solution for 20 seconds using a rectangular AC waveform voltage of 13 V anode voltage and 6 V cathode voltage, and was immersed in 20% sulfuric acid solution at 50 °C to rinse the surface , then rinse with w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com