Positive type photosensitive polyimide resin composition

A technology of polyimide resin and polyimide, which is applied in the direction of optics, optomechanical equipment, instruments, etc., can solve the problem of Tg drop of aromatic polyimide resin, achieve low dielectric constant, simple preparation, The effect of good photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

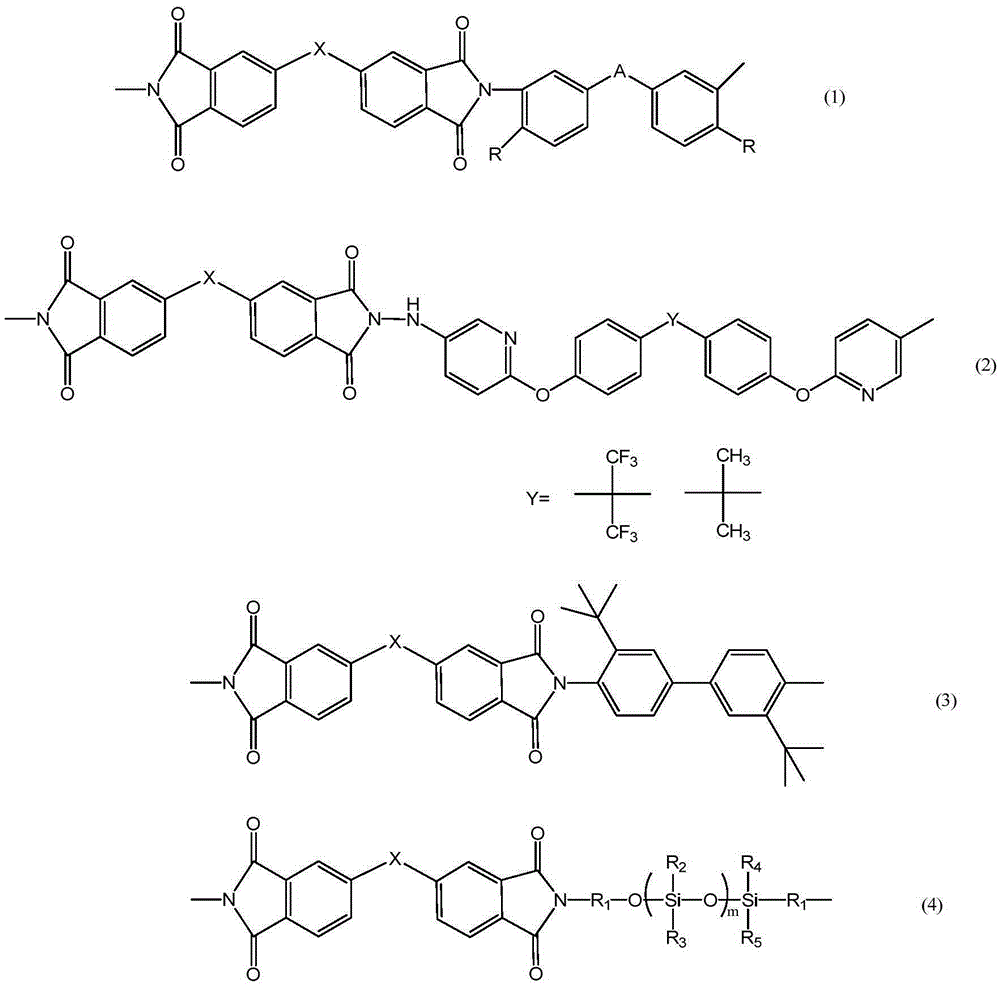

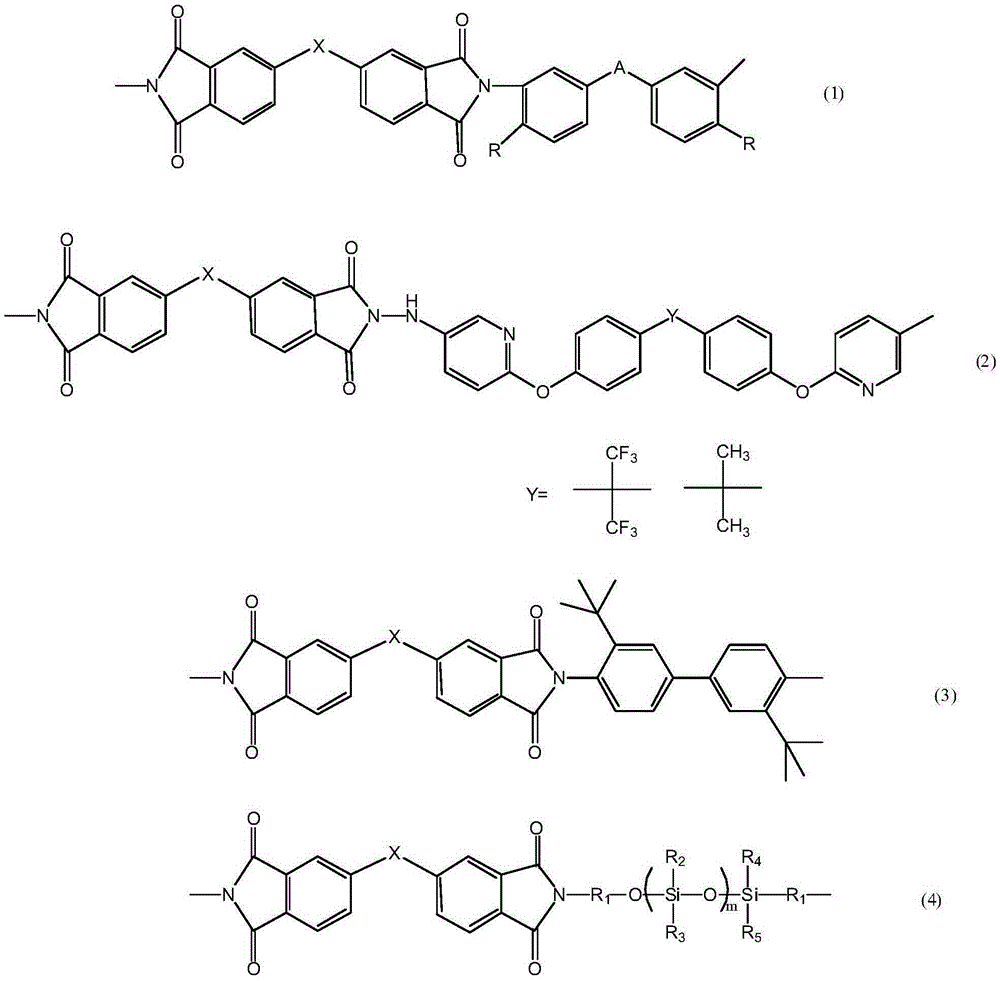

Method used

Image

Examples

preparation example Construction

[0046] Preparation of photosensitive polyimide varnish: In the obtained alkali-soluble polyimide resin, add a certain amount of epoxy resin or benzoxazine crosslinking agent, and add solvent γ-butyrolactone at the same time, at room temperature Stir and dissolve. After the dissolution is uniform, add a certain amount of quinonediazide compound under dark light, stir and dissolve, dissolve evenly and filter to obtain a photosensitive polyimide varnish, and store it in dark light for future use.

[0047] Coating, exposure, development and curing of photosensitive polyimide. The specific steps are as follows: first, the film is coated by spin coating, and then pre-baked for 7 minutes (at 150° C.). After the pre-baked, exposure is carried out for 3 minutes respectively. Subsequently, a developing experiment was carried out (the developing solution was 2.38wt% tetramethylammonium hydroxide aqueous solution), and the developing time was 3 minutes, and then the developed samples were...

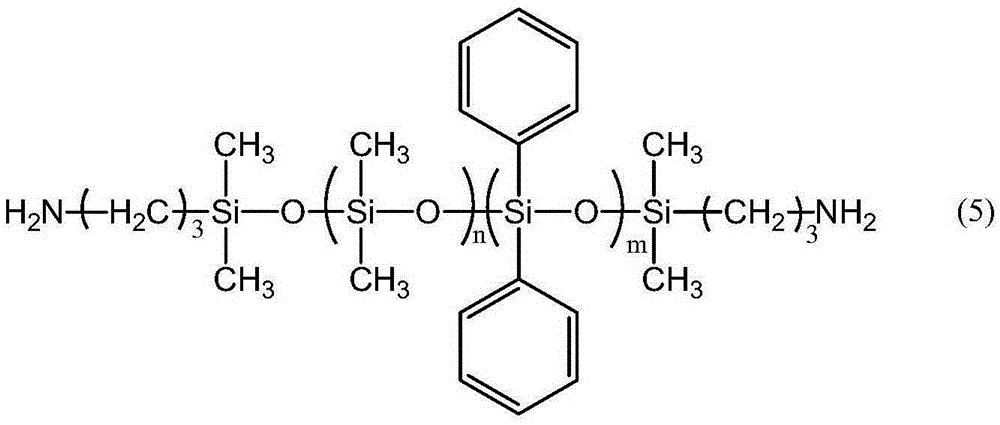

Embodiment 1

[0051] Under dry nitrogen flow, first make 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (hereinafter referred to as BAHF) 2.75g (7.5mmo), 1,3-bis(3-aminopropyl ) Tetramethyldisiloxane 0.124g (0.5mmol) was dissolved in 8g of N-methyl-2-pyrrolidone (NMP), then 3.12g (10mmol) of bis(3,4-dicarboxyphenyl) was added thereto ) ether dianhydride (ODPA), add 2g of NMP, make it react at 60°C for 45min, then add 0.327g (3mmol) of 4-aminophenol as an end-capping agent, and react for 0.5h. This was followed by stirring at 180° C. for 4 hours. After stirring, the solution was poured into 300 mL of water to obtain a white precipitate. Collect the precipitate by filtration, wash it with water three times, then wash it three times with hot water, and finally dry it in a vacuum dryer at 80°C for 20 hours to obtain a white alkali-soluble polyimide resin powder A-1.

[0052] Preparation of photosensitive polyimide varnish: Add 0.6 g of bisphenol A type epoxy resin to 3 g of the obtained r...

Embodiment 2

[0055] Under dry nitrogen flow, first make 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (hereinafter referred to as BAHF) 2.93g (8mmo), 3,3-di-tert-butylbenzidine 0.1468g (0.5mmol), be dissolved in the N-methyl-2-pyrrolidone (NMP) of 8g, then add 3.12g (10mmol) bis(3,4-dicarboxyphenyl) ether dianhydride (ODPA) to it subsequently, in Add 2g of NMP, make it react at 60°C for 45min, then add 0.327g (3mmol) of 4-aminophenol as an end-capping agent, and react for 0.5h. This was followed by stirring at 180° C. for 4 hours. After stirring, the solution was poured into 300 mL of water to obtain a white precipitate. Collect the precipitate by filtration, wash it with water three times, then wash it three times with hot water, and finally dry it in a vacuum dryer at 80°C for 20 hours to obtain a white alkali-soluble polyimide resin powder (A-2).

[0056]The preparation of photosensitive polyimide varnish: in the resin alkali-soluble polyimide resin (A-2) 3g that obtains, add bis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com