Method for fast synthesizing ZSM-5 molecular sieves

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of increasing the cost of molecular sieve, consumption of organic template agents, environmental pollution, etc., and achieve crystallization The effect of good degree, low cost and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

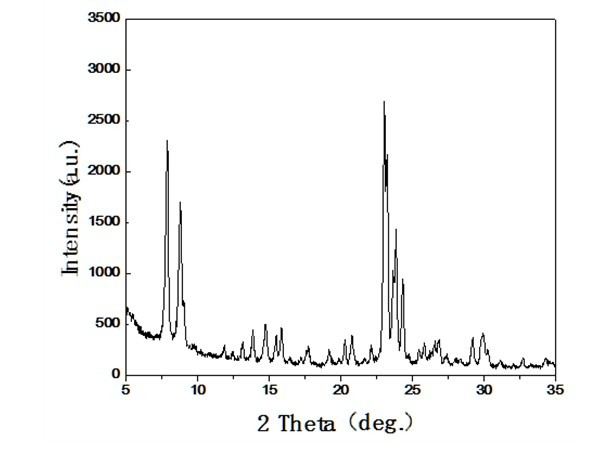

[0030] Embodiment 1: The method for rapidly synthesizing ZSM-5 molecular sieve adopts the following process steps.

[0031] (1) First mix 0.61g aluminum isopropoxide, 16.09g deionized water and 0.20g NaOH to form solution A, then mix 12.48g tetrapropylammonium hydroxide solution (25%wt Aqueous solution) mixed to form solution B (wherein SiO 2 / Al 2 o 3 , OH - / SiO 2 , R / SiO 2 and H 2 O / SiO 2 The molar ratios are 40, 0.28, 0.2 and 21.7), solution B was added drop by drop into solution A under vigorous stirring to obtain a well-mixed sol-gel, and aged for 4 hours with stirring at room temperature.

[0032] (2) Take out the aged sol-gel and put it in an oven to dry at 80°C for 2.5 hours, and grind it into powdery dry rubber powder.

[0033] (3) Put the dry rubber powder into a stainless steel crystallization kettle lined with polytetrafluoroethylene, add water, and crystallize at 150°C for 24h.

[0034] (4) The precipitate (crystallized product) is washed by centrifugati...

Embodiment 2

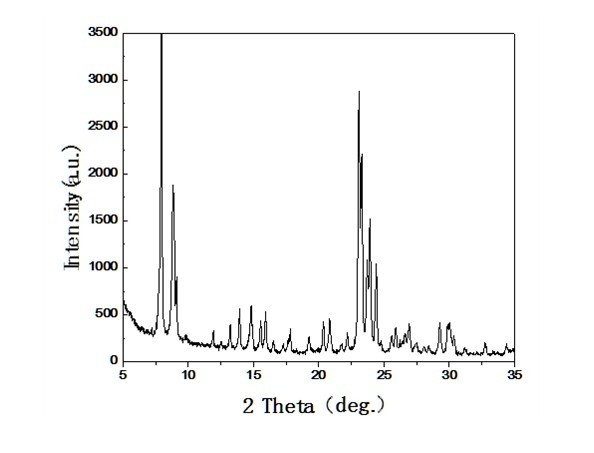

[0035]Embodiment 2: The method for rapidly synthesizing ZSM-5 molecular sieve adopts the following process steps.

[0036] (1) First mix 1.50g of aluminum nitrate, 34.94g of deionized water and 1.20g of NaOH to form solution A, then mix 12.48g of tetraethyl orthosilicate, 10g of deionized water and 4.88g of tetrapropylammonium hydroxide solution (25 %wt aqueous solution) mixed to form solution B (wherein SiO 2 / Al 2 o 3 , OH - / SiO 2 , R / SiO 2 and H 2 O / SiO 2 The molar ratios are 30, 0.6, 0.1 and 45), solution B was added drop by drop into solution A under vigorous stirring to obtain a well-mixed sol-gel, and aged for 4 hours under stirring at room temperature.

[0037] (2) Take out the aged sol-gel and put it in an oven to dry at 70°C for 3 hours, and grind it into powdery dry glue powder.

[0038] (3) Put the dry rubber powder into a stainless steel crystallization kettle lined with polytetrafluoroethylene, add water, and crystallize at 150°C for 24h.

[0039] (4) T...

Embodiment 3

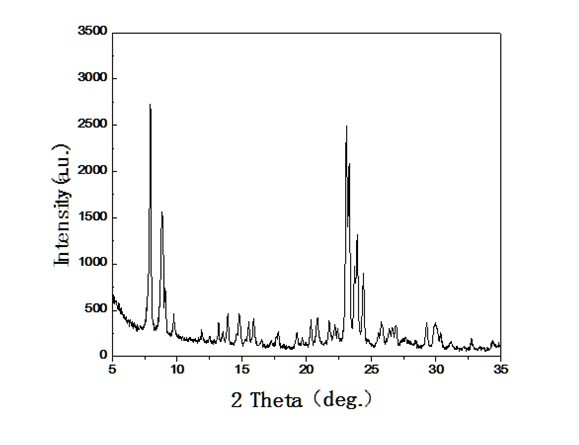

[0040] Embodiment 3: The method for rapidly synthesizing ZSM-5 molecular sieve adopts the following process steps.

[0041] (1) First mix 0.82g aluminum isopropoxide, 17.78g deionized water and 0.80g NaOH to make solution A, then mix 24.96g tetrapropylammonium hydroxide solution (25%wt of Aqueous solution) mixed to form solution B (wherein SiO 2 / Al 2 o 3 , OH - / SiO 2 , R / SiO 2 and H 2 O / SiO 2 The molar ratios are 60, 0.37, 0.2 and 15), and the solution B is dropped into the solution A drop by drop under vigorous stirring to obtain a well-mixed sol-gel, which is aged at room temperature for 4 hours.

[0042] (2) Take out the aged sol-gel and put it in an oven to dry at 80°C for 2 hours, and grind it into powdery dry glue powder.

[0043] (3) Put the dry rubber powder into a stainless steel crystallization kettle lined with polytetrafluoroethylene, add water, and crystallize at 160°C for 20h.

[0044] (4) The precipitate (crystallized product) was washed by centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com