System for producing fresh water

A technology for manufacturing systems and fresh water, applied in seawater treatment, energy waste water treatment, water/sewage treatment, etc., can solve the problems of deteriorating osmotic membranes, lowering the purity of fresh water, corrosion of metal structures by ammonia water, etc. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

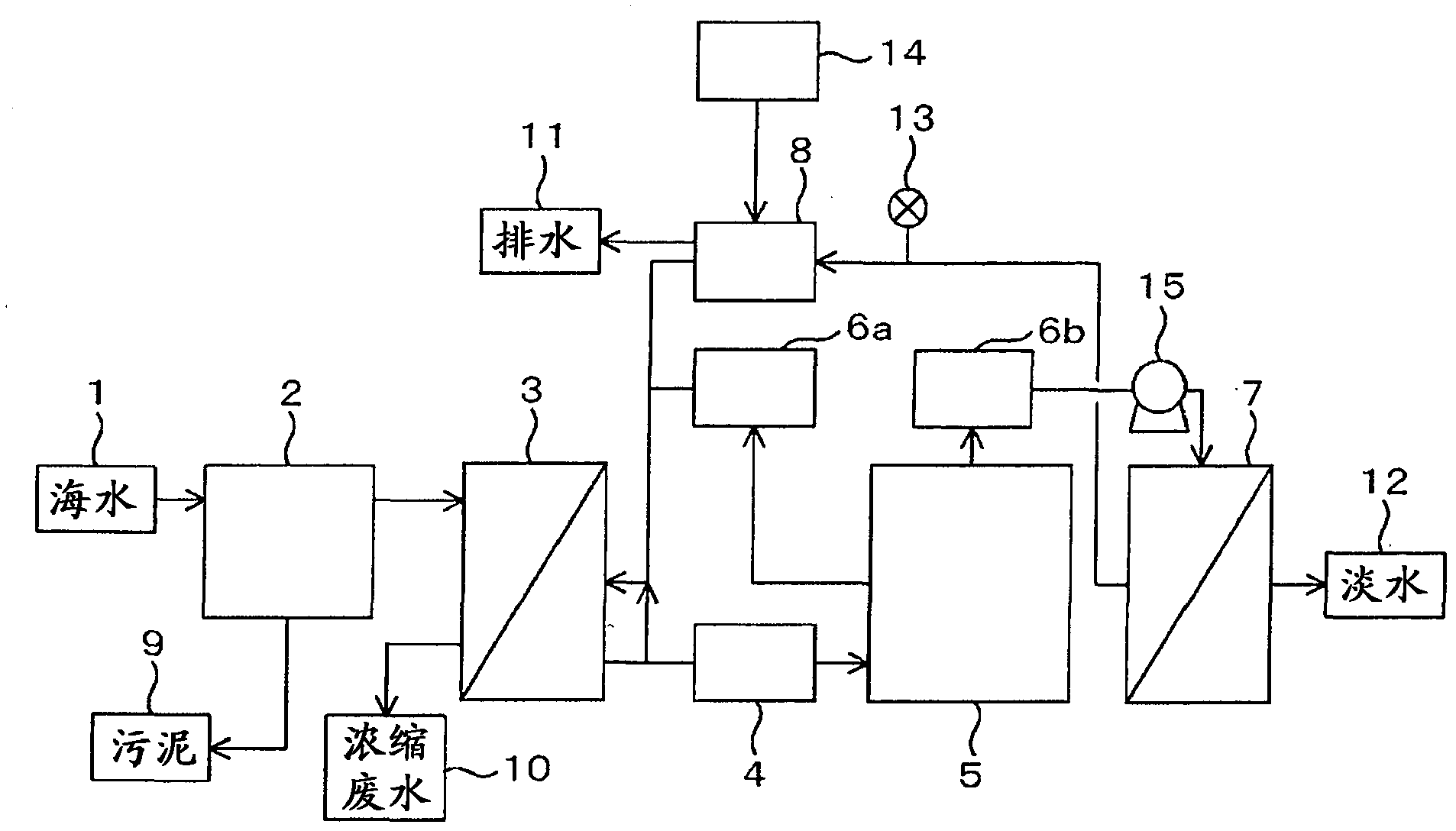

[0048] figure 1It is a block diagram of the fresh water production system concerning 1st Embodiment of this invention. The fresh water production system of the present embodiment consists of a pretreatment device 2 that takes in seawater, a forward osmosis membrane treatment device 3 connected to the pretreatment device 2, a crystallization device 5 connected to the forward osmosis membrane treatment device 3 via a cooling device 4, and a Heating device 6b, water pump 15 are connected with the reverse osmosis membrane treatment device 7 of crystallization device 5, the switching device 8 that is connected with reverse osmosis membrane treatment device 7, are installed on the piping that connects reverse osmosis membrane treatment device 7 and switching device 8 The chloride ion sensor 13 and the storage tank 14 connected to the switching device 8 constitute, the crystallization device 5 is connected to the forward osmosis membrane processing device 3 via the heating device 6a,...

no. 2 approach 〕

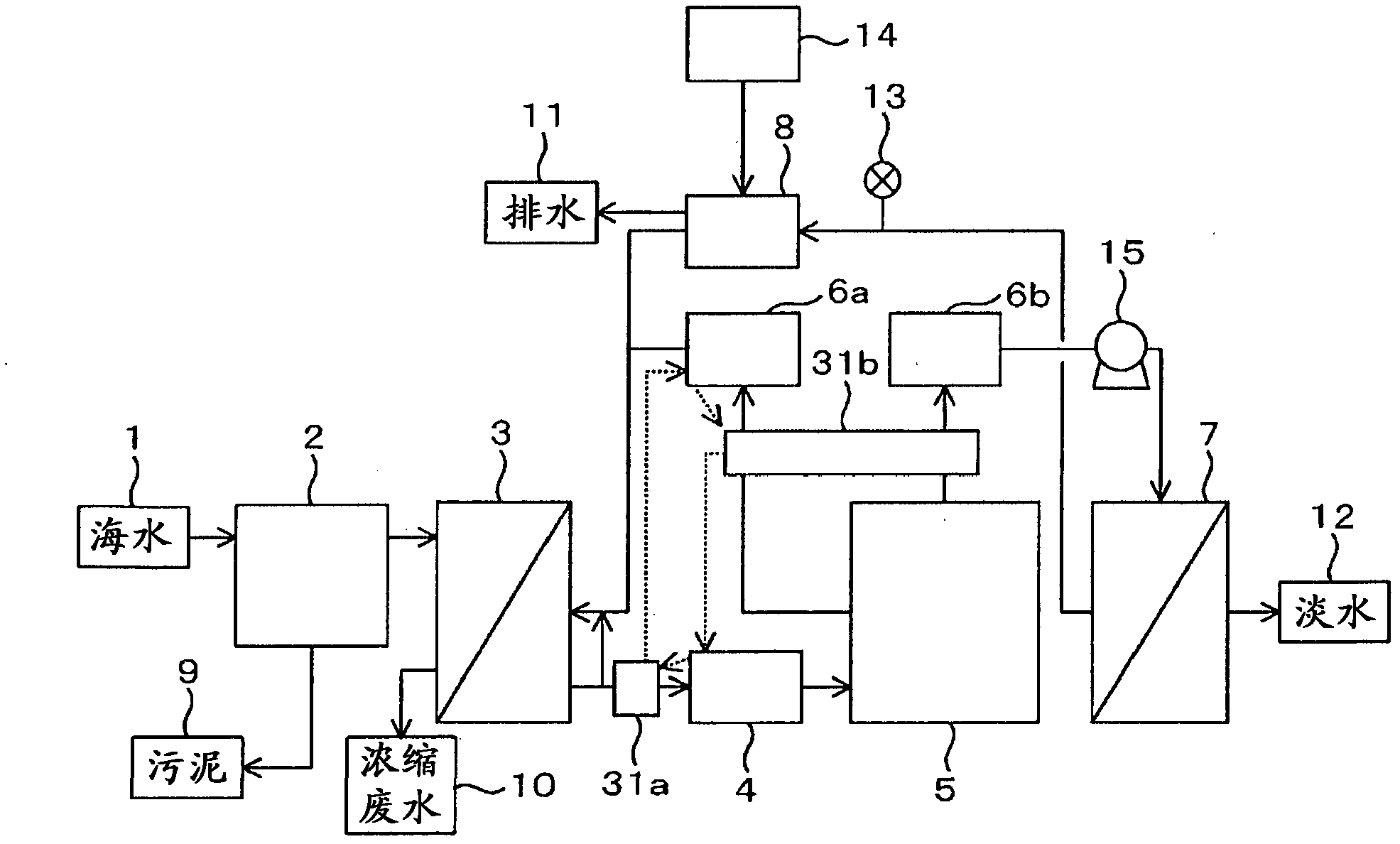

[0083] image 3 It is a block diagram of the fresh water production system concerning 2nd Embodiment of this invention. The system of this embodiment is based on the structure of 1st Embodiment, and the structure which provided the heat exchanger 31a, 31b between the crystallization apparatus 5 and the heating apparatus 6a, 6b.

[0084] In the heat exchanger 31 a, heat is recovered from the hypertonic solution discharged from the forward osmosis membrane treatment device 3 . The recovered heat is transferred to the heat exchanger 31b via the fluid used as the medium, and is again heat-exchanged with the slurry and supernatant discharged from the crystallizer 5 . The fluid used as the heat medium circulates between the heat exchangers 31a and 31b, and is used when cooling the hypertonic solution before the crystallization treatment and heating the slurry and supernatant after the crystallization treatment are continuously performed. When the predetermined water temperature is...

no. 3 approach 〕

[0089] Figure 4 It is a block diagram of the fresh water production system which concerns on 3rd Embodiment of this invention. The system of the present embodiment is based on the constitution of the first embodiment, and a pressure transducer 41 is set between the flow path connecting the forward osmosis membrane treatment device 3 and the cooling device 4 and the flow path connecting the heating device 6b and the water pump 15 composition.

[0090] The hypertonic solution discharged from the forward osmosis membrane treatment device 3 is introduced into the pressure transducer 41 . The pressure of the hypertonic solution is transmitted to the supernatant water of the crystallization device 5 connected to the pressure transducer 41 . After further obtaining the pressure required only for the reverse osmosis membrane treatment from the water pump 15 , the pressurized supernatant water is supplied to the reverse osmosis membrane treatment device 7 . The pressure-reduced hyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com