Method for preparing titanium dioxide nano multi-level structure thin film on conductive glass

A technology of titanium dioxide and conductive glass, which is applied in the field of preparing titanium dioxide nanoscale multi-level structure films on conductive glass, can solve the problems of complex process, difficult control of nanostructure size and shape, harsh reaction conditions, etc., and achieve simple operation, size and shape The effect of easy appearance, size and shape control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

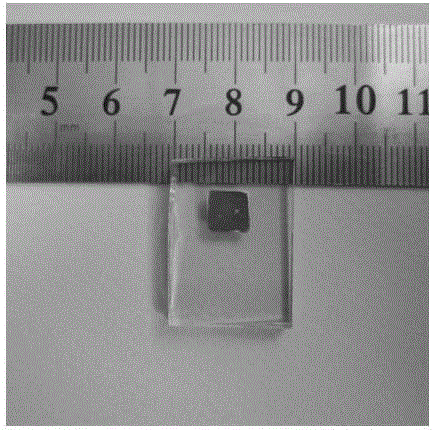

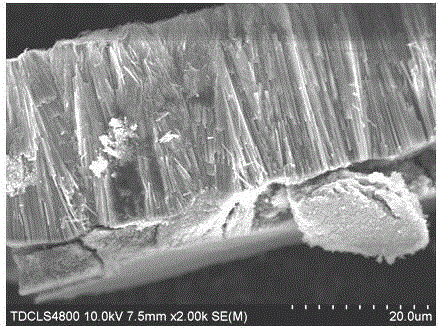

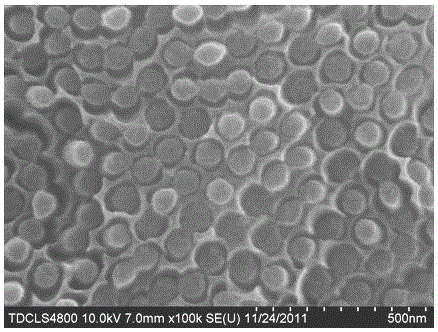

[0018] Make the area 60x55mm 2 , a polished pure titanium sheet with a thickness of 0.1 mm was ultrasonically cleaned in acetone, ethanol and deionized water for 10 min in sequence; As the anode, the platinum electrode is used as the cathode, the electrode distance is 3cm, the voltage is 60V, the electrolytic cell is kept at a constant temperature of 25°C, anodized for 10h, and the electrolyte is continuously stirred during the treatment process; the obtained sample is ultrasonically cleaned in ethanol for 15min, and then immersed in 100ml of 1% hydrofluoric acid solution, let stand at 25°C for 2 minutes, separate the film from the titanium sheet, take out the titanium dioxide film, wash it with deionized water until it is neutral, and dry it in the air; Coat a layer of 2 μm titanium dioxide nanoparticle film, transfer the titanium dioxide nanotube array film prepared by anodic oxidation to conductive glass, and dry at 200°C for 1 hour; immerse the titanium dioxide nanotube ar...

Embodiment 2

[0020] Make the area 60x55mm 2 , a polished pure titanium sheet with a thickness of 0.1 mm was ultrasonically cleaned in acetone, ethanol and deionized water for 10 min in sequence; As the anode, the platinum electrode is used as the cathode, the electrode distance is 3cm, the voltage is 60V, the electrolytic cell is kept at a constant temperature of 25°C, anodized for 8h, and the electrolyte solution is continuously stirred during the treatment process; the obtained sample is ultrasonically cleaned in ethanol for 15min, and then immersed in 100ml of 1% hydrofluoric acid solution by mass fraction, let stand at 25°C for 1min, separate the film from the titanium sheet, take out the titanium dioxide film and rinse it with deionized water until it is neutral, and dry it in the air; Coat a layer of 2 μm titanium dioxide nanoparticle film, transfer the titanium dioxide nanotube array film prepared by anodic oxidation to conductive glass, and dry at 200°C for 1 hour; immerse the tita...

Embodiment 3

[0022] Make the area 60x55mm 2 , a polished pure titanium sheet with a thickness of 0.1 mm was ultrasonically cleaned in acetone, ethanol and deionized water for 10 min in sequence; As the anode, the platinum electrode is used as the cathode, the electrode distance is 3cm, the voltage is 60V, the electrolytic cell is kept at a constant temperature of 25°C, anodized for 8h, and the electrolyte solution is continuously stirred during the treatment process; the obtained sample is ultrasonically cleaned in ethanol for 15min, and then immersed in 100ml of 1% hydrofluoric acid solution by mass fraction, let stand at 25°C for 1min, separate the film from the titanium sheet, take out the titanium dioxide film and rinse it with deionized water until it is neutral, and dry it in the air; Coat a layer of 2 μm titanium dioxide nanoparticle film, transfer the titanium dioxide nanotube array film prepared by anodic oxidation to conductive glass, and dry at 200°C for 1 hour; immerse the tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com