Tolyltriazole-containing polyethylene glycol protein modifier, preparation method thereof and application thereof

A protein modification, polyethylene glycol technology, applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve problems such as large differences between each other, cumbersome preparation methods, and unfavorable large-scale production of enterprises, and achieve cost The effect of low cost, simple process and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

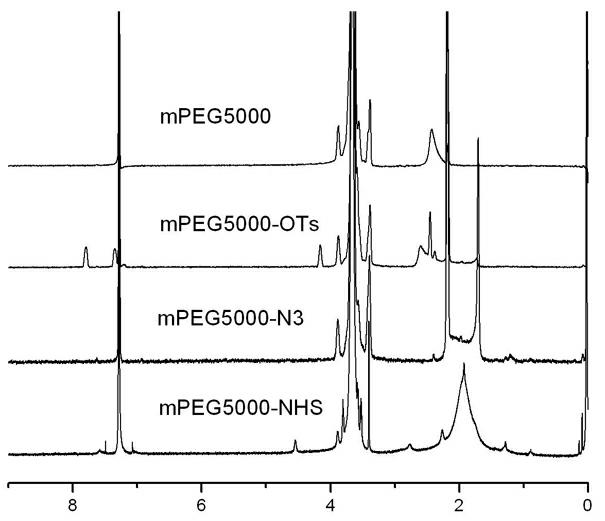

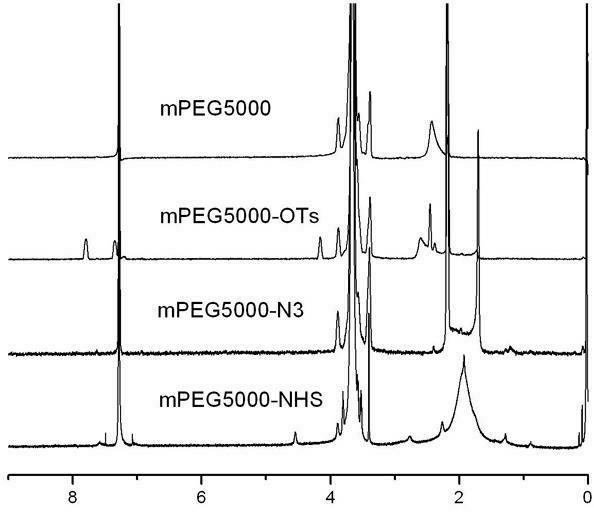

[0040] Example 1: with mPEG 5000 (M.W.5000) as the starting material for the preparation of mPEG 5000 -NHS (A is 0), its preparation steps are:

[0041] 1. Preparation of p-tosylated mPEG 5000 -OTs: 20g mPEG 5000Dissolve in 20ml of dichloromethane, add 400mg of triethylamine, 50mg of p-dimethylaminopyridine and 3.8g of p-toluenesulfonyl chloride under stirring condition. The reaction solution was stirred at room temperature for 24 hours, then diluted with 200ml of dichloromethane, washed once with 100ml of cold 4M hydrochloric acid and 100ml of water, and finally dried over anhydrous sodium sulfate. The filtered organic solution was concentrated to about 30ml, and then slowly added dropwise to 400ml of anhydrous ether, and a large amount of white precipitates precipitated out. The precipitate was filtered and vacuum-dried to obtain the target product mPEG 5000 -OTs 19.5g.

[0042] 2. Preparation of Azidated mPEG 5000 -N 3 : 10g mPEG 5000 -OTs was dissolved in 50ml of ...

Embodiment 2

[0044] Example 2: Using mPEG 5000 (M.W.5000) as the starting material for the preparation of mPEG 5000 -NHS (A is 4), its preparation steps are:

[0045] 1. Preparation of p-tosylated mPEG 5000 -OTs: 20g mPEG 5000 Dissolve in 20ml of dichloromethane, add 400mg of triethylamine, 50mg of p-dimethylaminopyridine and 3.8g of p-toluenesulfonyl chloride under stirring condition. The reaction solution was stirred at room temperature for 24 hours, then diluted with 200ml of dichloromethane, washed once with 100ml of cold 4M hydrochloric acid and 100ml of water, and finally dried over anhydrous sodium sulfate. The filtered organic solution was concentrated to about 30ml, and then slowly added dropwise to 400ml of anhydrous ether, and a large amount of white precipitates precipitated out. The precipitate was filtered and vacuum-dried to obtain the target product mPEG 5000 -OTs 19.5g.

[0046] 2. Preparation of Azidated mPEG 5000 -N 3 : 10g mPEG 5000 -OTs was dissolved in 50ml o...

Embodiment 3

[0048] Example 3: Using mPEG 5000 (M.W.5000) as the starting material for the preparation of mPEG 5000 -NHS (A is 10), its preparation steps are:

[0049] 1. Preparation of p-tosylated mPEG 5000 -OTs: 20g mPEG 5000 Dissolve in 20ml of dichloromethane, add 400mg of triethylamine, 50mg of p-dimethylaminopyridine and 3.8g of p-toluenesulfonyl chloride under stirring condition. The reaction solution was stirred at room temperature for 24 hours, then diluted with 200ml of dichloromethane, washed once with 100ml of cold 4M hydrochloric acid and 100ml of water, and finally dried over anhydrous sodium sulfate. The filtered organic solution was concentrated to about 30ml, and then slowly added dropwise to 400ml of anhydrous ether, and a large amount of white precipitates precipitated out. The precipitate was filtered and vacuum-dried to obtain the target product mPEG 5000 -OTs 19.5g.

[0050] 2. Preparation of Azidated mPEG 5000 -N 3 : 10g mPEG 5000 -OTs was dissolved in 50ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com