Environment-friendly flame-retardant polyvinyl chloride cable insulating material and preparation method thereof

A technology for flame-retardant polyvinyl chloride and cable insulation, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., and can solve problems such as toxic and corrosive fumes, fire fighting, and loss of people's lives and property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

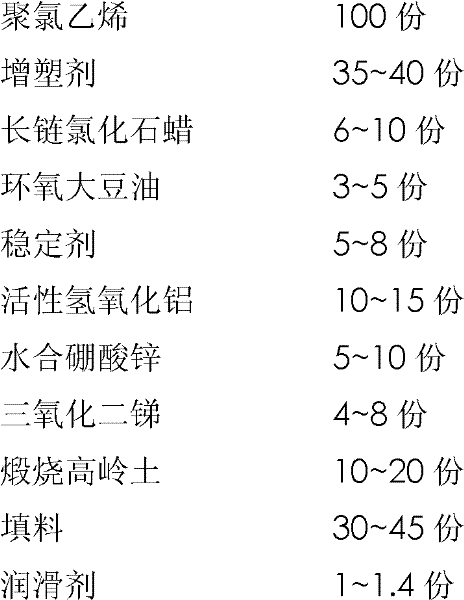

Method used

Image

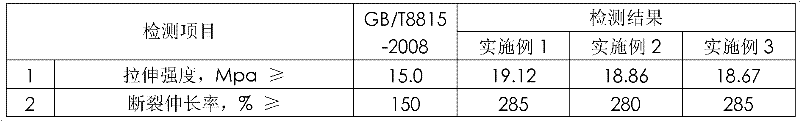

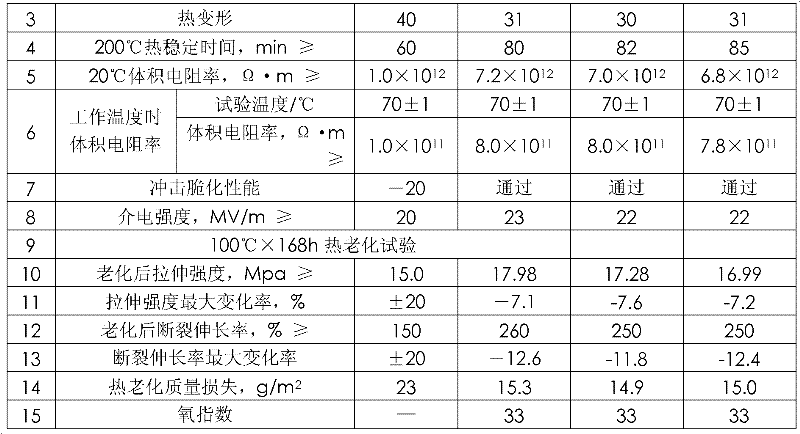

Examples

Embodiment 1

[0022] First put (the following are parts by weight) 100 parts of polyvinyl chloride and 6 parts of stabilizer into a high-speed mixer for high-speed mixing. When the temperature rises to 60°C, add 40 parts of plasticizer UN488, 6 parts of long-chain chlorine Chemical paraffin and 4 parts of epoxidized soybean oil, when the temperature reaches 80°C, add 5 parts of antimony trioxide, 8 parts of hydrated zinc borate, and 12 parts of activated aluminum hydroxide, when the temperature reaches 90°C, add 10 parts of calcined Kaolin, 15 parts of heavy calcium carbonate and 20 parts of nano calcium carbonate, when the temperature reaches 100 ° C, add 0.6 parts of stearic acid and 0.6 parts of butyl stearate, when the temperature reaches 110 ° C, stop high-speed mixing. Unload the material into the low-speed mixer for low-speed mixing and cooling, unload the cooled material into the hopper elevator, add it to the twin-screw extruder for mixing, extrude, granulate and pack.

Embodiment 2

[0024] First put (the following are parts by weight) 100 parts of polyvinyl chloride and 5 parts of stabilizer into a high-speed mixer for high-speed mixing. When the temperature rises to 60°C, add 35 parts of plasticizer UN488, 4 parts of long-chain chlorine Chemical paraffin and 3 parts of epoxidized soybean oil, when the temperature reaches 80°C, add 6 parts of antimony trioxide, 10 parts of hydrated zinc borate and 14 parts of activated aluminum hydroxide, when the temperature reaches 90°C, add 15 parts of calcined kaolin 10 parts of heavy calcium carbonate and 25 parts of nano-calcium carbonate, when the temperature reaches 100 ° C, add 0.5 parts of stearic acid and 0.5 parts of butyl stearate, when the temperature reaches 110 ° C, stop high-speed mixing. Unload the material into the low-speed mixer for low-speed mixing and cooling, unload the cooled material into the hopper elevator, add it to the twin-screw extruder for mixing, extrude, granulate and pack.

Embodiment 3

[0026] First put (the following are parts by weight) 100 parts of polyvinyl chloride and 7 parts of stabilizer into a high-speed mixer for high-speed mixing. When the temperature rises to 60 ° C, add 45 parts of plasticizer UN488, 10 parts of long-chain chlorine Chemical paraffin and 5 parts of epoxidized soybean oil, when the temperature reaches 80°C, add 4 parts of antimony trioxide, 6 parts of hydrated zinc borate and 10 parts of activated aluminum hydroxide, when the temperature reaches 90°C, add 20 parts of calcined kaolin 10 parts of heavy calcium carbonate and 20 parts of nano calcium carbonate, when the temperature reaches 100 ° C, add 0.7 parts of stearic acid and 0.7 parts of butyl stearate, when the temperature reaches 110 ° C, stop high-speed mixing. Unload the material into the low-speed mixer for low-speed mixing and cooling, unload the cooled material into the hopper elevator, add it to the twin-screw extruder for mixing, extrude, granulate and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com