High-density low-friction fracturing fluid

A fracturing fluid and low-friction technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of increased formation damage, prolonged cross-linking time, and high cost of bromine salts, and achieves low formation damage, Inexpensive, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Fracturing fluid formula 1 of the present invention (density is 1.16g / cm 3 )

[0044] Weighting agent sodium nitrate weight ratio: 20%

[0045] Thickener hydroxypropyl guar gum weight ratio: 0.50%

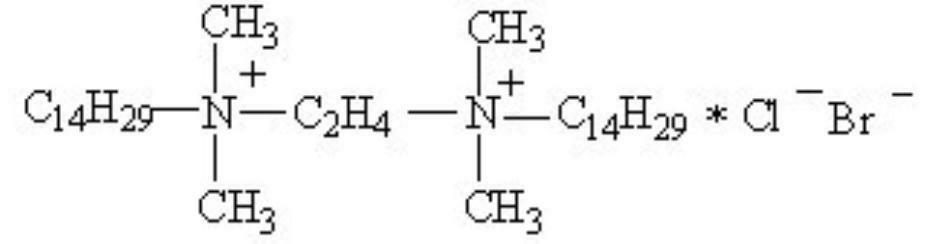

[0046] Drainage aid gemini surfactant weight ratio: 0.5%,

[0047] pH regulator Na 2 CO 3 Weight ratio: 0.1%

[0048] Fungicide dodecyltrimethylammonium chloride weight ratio: 0.15%

[0049] Clay stabilizer polyquaternium weight ratio: 0.5%

[0050] The temperature stabilizer is a compound formed by triethanolamine, methanol and polyoxyethylene sorbitan monolaurate Weight ratio: 0.5%

[0051] Water: 77.75%.

[0052] (2) Preparation of 1000g of the above-mentioned aggravated fracturing fluid

[0053]Add 777.5g of water to the waring mixer, then add 200g of sodium nitrate, start the mixer to fully dissolve it; add 5.0g of thickener hydroxypropyl guar gum under continuous stirring, swell for 30 minutes and thicken, then add 1g of sodium carbonate in turn , fungici...

Embodiment 2

[0057] (1) Fracturing fluid formula 2 of the present invention (density is 1.30g / cm 3 )

[0058] Weighting agent sodium nitrate weight ratio: 40%

[0059] Thickener hydroxypropyl guar gum weight ratio: 0.52%

[0060] Drainage aid gemini surfactant weight ratio: 0.5%,

[0061] pH regulator Na 2 CO 3 Weight ratio: 0.1%

[0062] Fungicide dodecyltrimethylammonium chloride weight ratio: 0.15%

[0063] Clay stabilizer polyquaternium weight ratio: 0.5%

[0064] Temperature stabilizer triethanolamine, methanol and polyoxyethylene sorbitan monolaurate compound weight ratio: 0.5%

[0065] Water: 57.73%.

[0066] (2) Preparation of 1000g of the above-mentioned aggravated fracturing fluid

[0067] Add 577.3g of water to the waring mixer, then add 400g of sodium nitrate, start the mixer to fully dissolve it; add 5.2g of thickener hydroxypropyl guar gum under continuous stirring, swell for 30 minutes and thicken, then add sodium carbonate 1.0 g, fungicide dodecyltrimethylammonium...

Embodiment 3

[0072] (1) Fracturing fluid formula three of the present invention (density is 1.35g / cm 3 )

[0073] Weighting agent sodium nitrate weight ratio: 46.5%

[0074] Thickener hydroxypropyl guar gum weight ratio: 0.55%

[0075] Drainage aid gemini surfactant weight ratio: 1.0%,

[0076] pH regulator Na 2 CO 3 Weight ratio: 0.15%

[0077] Fungicide dodecyltrimethylammonium chloride weight ratio: 0.15%

[0078] Clay stabilizer polyquaternium weight ratio: 1.0%

[0079] Temperature stabilizer organic amine compound weight ratio: 1.0%

[0080] Water: 49.65%.

[0081] (2) Preparation of 1000g of the above-mentioned aggravated fracturing fluid

[0082] Add 496.5g of water to the waring mixer, then add 465g of sodium nitrate, start the mixer to fully dissolve it; add 5.5g of thickener hydroxypropyl guar gum under continuous stirring, swell for 30min and thicken, then add sodium carbonate 1.5g g, fungicide dodecyltrimethylammonium chloride 1.5g, clay stabilizer polyquaternium 10....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com