Reaction device for manufacturing biodiesel

A reaction device, biodiesel technology, applied in the direction of biofuel, fatty acid esterification, etc., can solve the problems of low production efficiency, large environmental pollution, high production cost, etc., achieve the goal of changing the equilibrium state, shortening the reaction time, and reducing production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

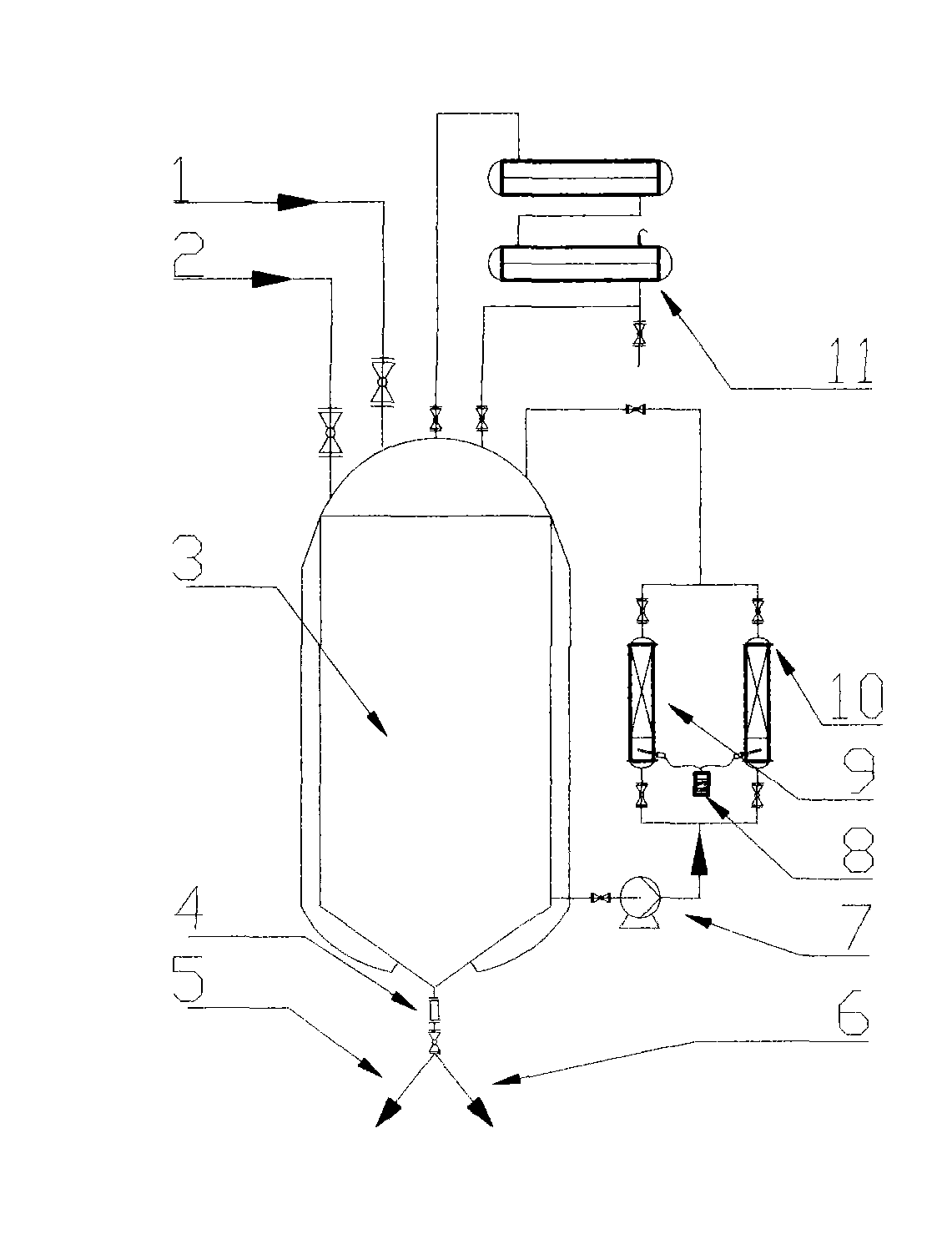

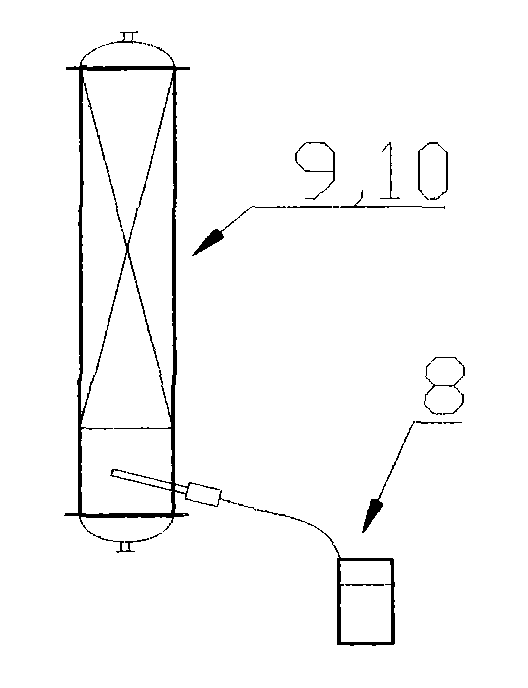

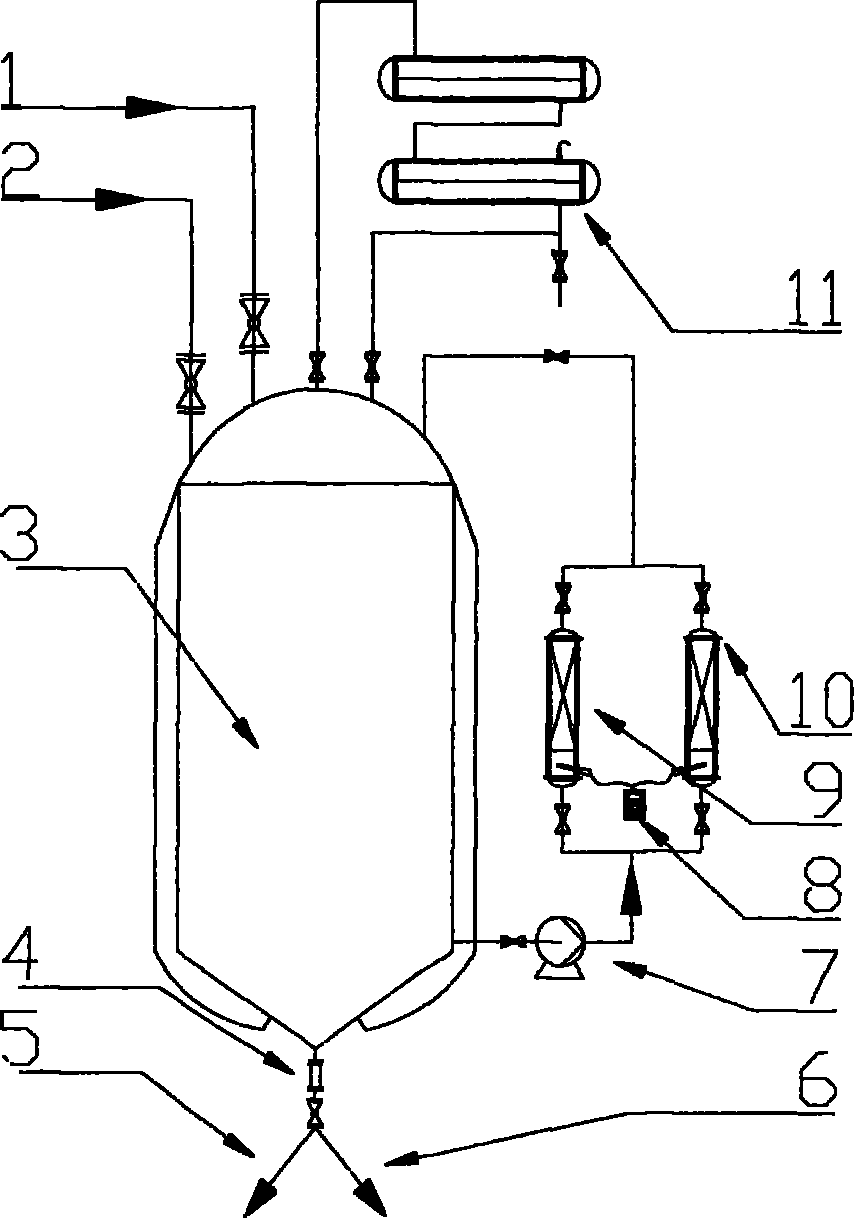

Method used

Image

Examples

Embodiment 1

[0013] Put 100kg of waste oil with an acid value of 19.2mgKOH / g and 30kg of methanol into the reactor 3 through inlet 1 and inlet 2 respectively, start the circulation pump 7, and enable the solid acid catalyst packing column 9 and reactor 3 to form a closed cycle by switching the valve In the pipeline, turn on the ultrasonic generator 8, and after 1.5 hours of ultrasonic-assisted reaction, the acid value is 1.25 mgKOH / g, close the solid acid catalyst packed column 9 valve, enable the solid alkali catalyst packed column 10 and the reactor 3 to form a closed circulation pipeline, Ultrasound assisted reaction for 15 minutes, and the transesterification reaction was completed. Turn off the ultrasonic generator 8, start the circulation pump 7, recover excess methanol through the methanol recovery condensing device 11, let it stand for 30 minutes after the methanol is completely recovered, drain the glycerol water produced by the reaction through the glass cup 4 from the outlet 5, a...

Embodiment 2

[0015] Put 100kg of acidified oil with an acid value of 195.2mgKOH / g and 30kg of methanol into the reactor 3 through inlet 1 and inlet 2 respectively, start the circulation pump 7, and activate the solid acid catalyst packing column 9 and reactor 3 to form a closed cycle by switching the valve Turn on the ultrasonic generator 8 in the pipeline, and after 3.0 hours of ultrasonic-assisted reaction, the acid value drops to 0.98 mgKOH / g, and the esterification reaction is completed. Turn off the ultrasonic generator 8, start the circulating pump 7, and recover excess methanol through the methanol recovery and condensing device 11. After the methanol is completely recovered, turn off the circulating pump 7, let it stand for 30 minutes, and drain the waste water generated by the reaction from the outlet 5 through the glass cup 4 , methyl ester is discharged from outlet 6, and the measured methyl ester content is 98.5%.

Embodiment 3

[0017] 100kg of jatropha seed oil with an acid value of 2.73mgKOH / g and 30kg of methanol are injected into the reactor 3 through the inlet 1 and the inlet 2 respectively, the circulation pump 7 is started, and the solid alkali catalyst packing column 10 and the reactor 3 are formed by switching the valve. The circulation pipeline is closed, the ultrasonic generator 8 is turned on, and the ultrasonic-assisted reaction is carried out for 15 minutes, and the transesterification reaction is completed. Turn off the ultrasonic generator 8, start the circulating pump 7, and recover excess methanol through the methanol recovery and condensing device 11. After the methanol is completely recovered, turn off the circulating pump 7, let it stand for 30 minutes, and discharge the glycerol water produced by the reaction through the glass sight cup 4 and out of the outlet 5. The methyl ester is discharged from the outlet 6, and the measured methyl ester content is 96.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com