Preparation method of in-situ synthesized carbon nanotube reinforced Mg-matrix composite

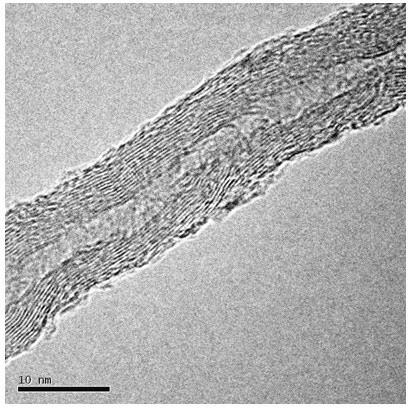

A carbon nanotube and composite material technology is applied in the field of preparation of carbon nanotube reinforced magnesium-based composite materials, which can solve the problems of the difficulty of dispersion of boron-doped carbon nanotubes, the problem of agglomeration of carbon nanotubes, and the like, and achieve structural integrity. , easy to operate, good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

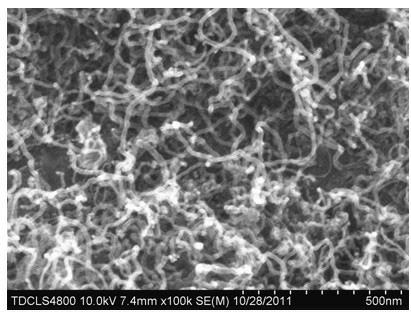

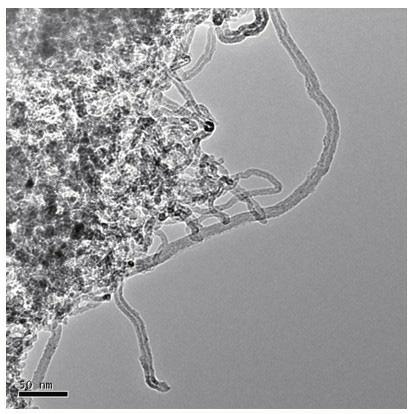

[0027] After mixing 0.64g of cobalt nitrate hexahydrate and 15.0g of magnesium powder, add it to 150ml of absolute ethanol. At the same time, add 0.21g of sodium hydroxide to 120ml of absolute ethanol. The concentration of the ethanol solution of sodium hydroxide is 0.044 mol / L, respectively ultrasonic 10min. Then, the ethanol solution of sodium hydroxide is dropped dropwise into the ethanol solution mixed with cobalt nitrate hexahydrate and magnesium powder, and magnetic stirring is carried out while titrating. After the titration, the mixed liquid was filtered with suction, and then vacuum-dried at a temperature of 50° C. for 2 hours to obtain a precursor powder. Take 10.0g of powder and place it in the constant temperature zone of the tube furnace, heat up to 400°C at a rate of 10°C / min and calcinate for 1 hour under the protection of argon, continue to heat up to 450°C at a rate of 10°C / min, and turn off the argon , feed hydrogen at a flow rate of 250mL / min, keep it at 45...

Embodiment 2

[0029] After mixing 0.33g of cobalt nitrate hexahydrate and 5.0g of magnesium powder, add it to 150ml of absolute ethanol. At the same time, add 0.11g of sodium hydroxide to 120ml of absolute ethanol. The concentration of the ethanol solution of sodium hydroxide is 0.023 mol / L, respectively ultrasonic 30min. Then, the ethanol solution of sodium hydroxide is dropped dropwise into the ethanol solution mixed with cobalt nitrate hexahydrate and magnesium powder, and magnetic stirring is carried out while titrating. After the titration, the mixed liquid was suction-filtered, and then vacuum-dried at a temperature of 80° C. for 5 hours to obtain a precursor powder. Take 1.0g of powder and place it in the constant temperature zone of the tube furnace, heat up to 300°C at a rate of 10°C / min and calcinate for 1 hour under the protection of argon, continue to heat up to 400°C at a rate of 10°C / min, and turn off the argon , flow in hydrogen at a flow rate of 100mL / min, keep the temperat...

Embodiment 3

[0031]After mixing 1.12g of cobalt nitrate hexahydrate and 5.0g of magnesium powder, add it to 150ml of absolute ethanol. At the same time, add 0.36g of sodium hydroxide to 120ml of absolute ethanol. The concentration of the ethanol solution of sodium hydroxide is 0.075 mol / L, respectively ultrasonic 60min. Then, the ethanol solution of sodium hydroxide is dropped dropwise into the ethanol solution mixed with cobalt nitrate hexahydrate and magnesium powder, and magnetic stirring is carried out while titrating. After the titration, the mixed liquid was suction-filtered, and then vacuum-dried at a temperature of 30° C. for 10 hours to obtain a precursor powder. Take 3.0g of powder and place it in the constant temperature zone of the tube furnace, heat up to 400°C at a rate of 10°C / min and calcinate for 3 hours under the protection of argon, continue to heat up to 500°C at a rate of 10°C / min, and turn off the argon , feed hydrogen at a flow rate of 150mL / min, keep the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com