Micro solid-phase extraction method of membrane-protected coordination polymer of polybrominated diphenyl ethers in multiple mediums

A technology of polybrominated diphenyl ethers and coordination polymers, which is applied in the fields of applied chemistry and analytical chemistry, can solve the problems of narrow independent application range, etc., and achieve the effects of shortening pretreatment time, high sensitivity and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

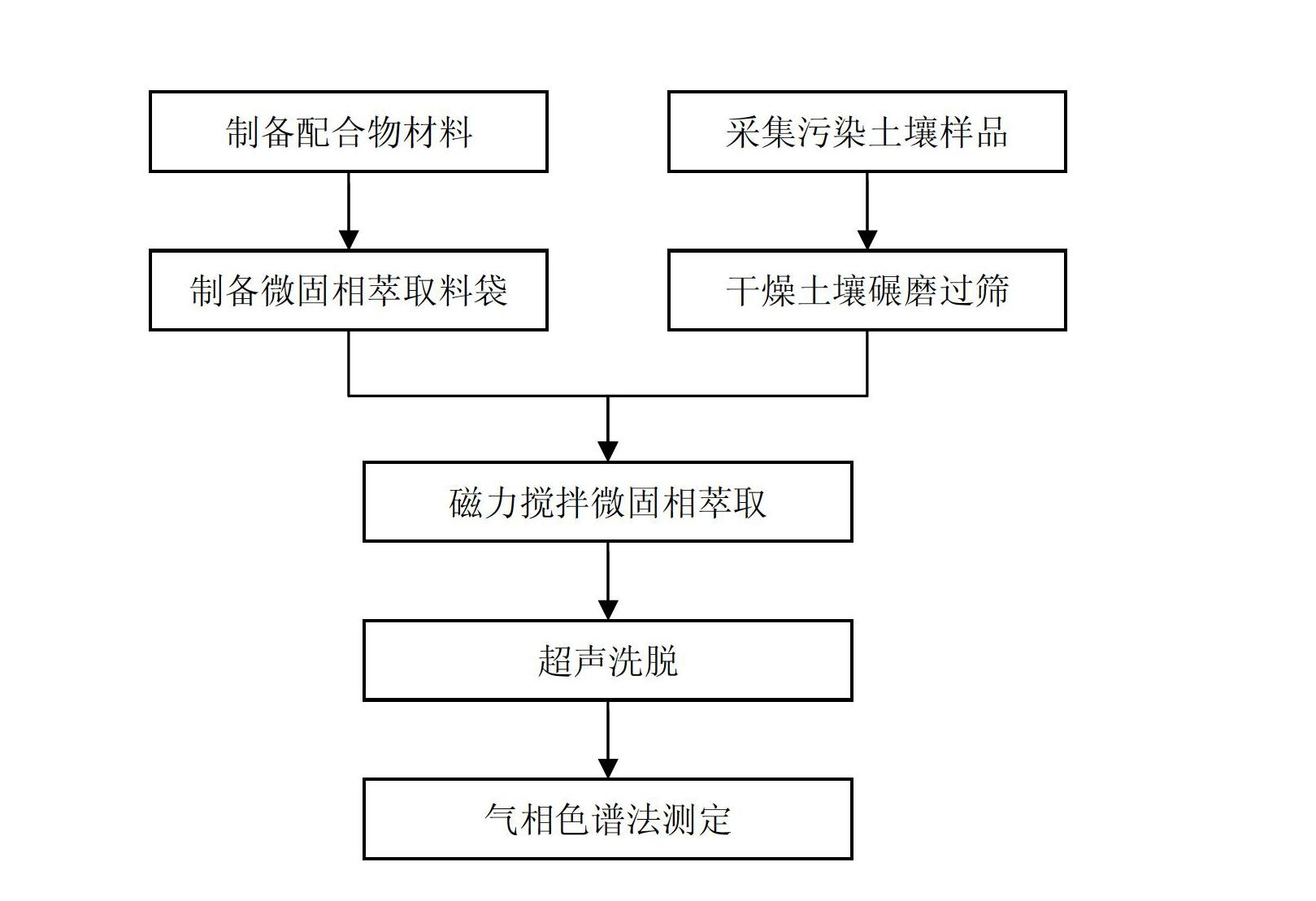

Method used

Image

Examples

Embodiment 1

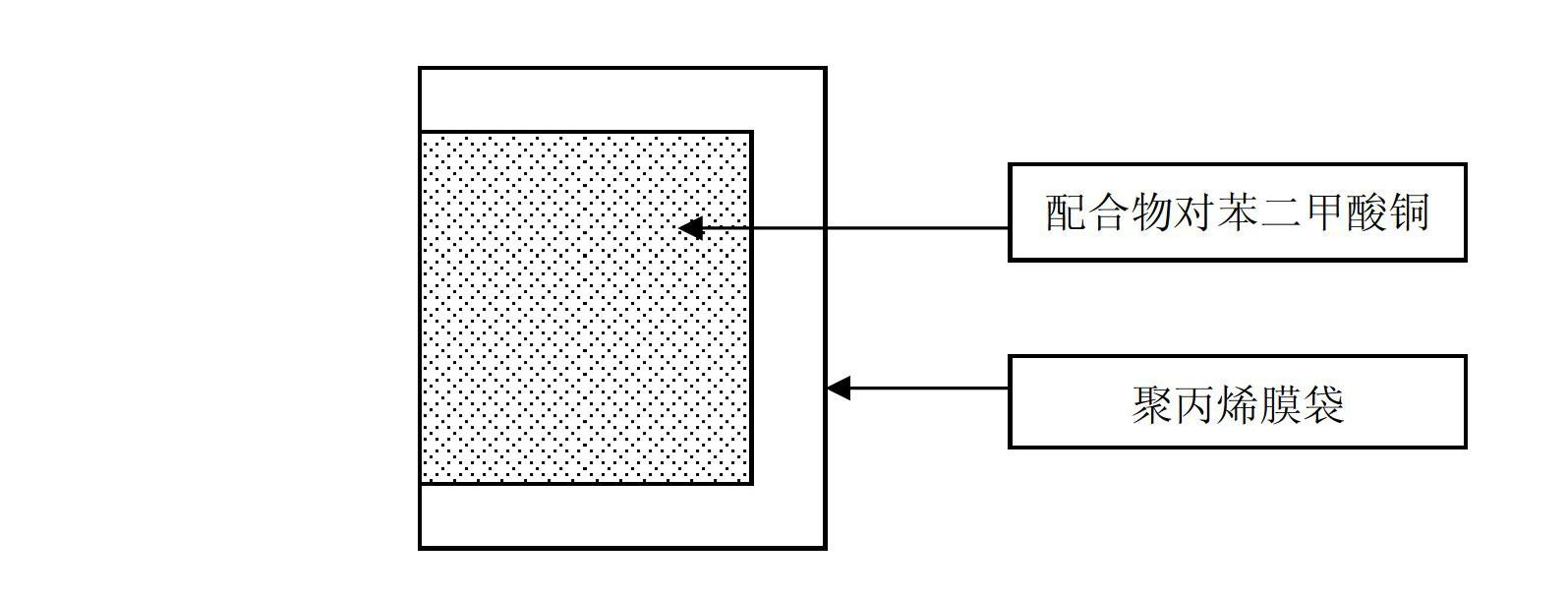

[0019] (1) Preparation of membrane-protected complex micro-SPE bags

[0020] Add 1mol of terephthalic acid and 2mol of sodium hydroxide into the secondary water, and after fully stirring and dissolving, add 1mol of copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O), stirring continuously for 3 hours until a blue powdery precipitate is formed in the solution. The filtered and air-dried blue powder was placed in a brown light bottle for later use.

[0021] Cut the 0.2μm pore diameter polypropylene film to 3.0cm×1.0cm size, fold the long side in half, heat seal the openings on both sides with a small plastic sealing machine, take 10mg of the above synthesized copper terephthalate complex and pour it into the polypropylene film bag, then completely seal the polypropylene film bag and trim the raw edges. Finally, the micro solid phase extraction bags with good sealing performance were cleaned ultrasonically for 5 minutes in pure water and methanol, and then soaked in methanol for ...

Embodiment 2

[0036] Embodiment 2 standard-added soil sample analysis

[0037] (1) Preparation of membrane-protected complex micro-SPE bags

[0038] Add 1mol of terephthalic acid and 2mol of sodium hydroxide into the secondary water, and after fully stirring and dissolving, add 1mol of copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O), stirring continuously for 3 hours until a blue powdery precipitate is formed in the solution. The filtered and air-dried blue powder was placed in a brown light bottle for later use.

[0039] Take a 0.22μm pore size polypropylene film and cut it to a size of 2.0cm×0.8cm, fold the long side in half, heat seal the openings on both sides with a small plastic sealing machine, take 10mg of the above synthesized copper terephthalate complex and pour it into the polypropylene film bag, then completely seal the polypropylene film bag and trim the raw edges. Finally, the micro solid phase extraction bags with good sealing performance were cleaned ultrasonically for...

Embodiment 3

[0051] Embodiment 3 standard-added soil sample analysis

[0052] (1) Preparation of membrane-protected complex micro-SPE bags

[0053] Add 1mol of terephthalic acid and 2mol of sodium hydroxide into the secondary water, and after fully stirring and dissolving, add 1mol of copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O), stirring continuously for 3 hours until a blue powdery precipitate is formed in the solution. The filtered and air-dried blue powder was placed in a brown light bottle for later use.

[0054] Take a 0.22μm pore diameter polypropylene film and cut it to a size of 3.0cm×1.5cm, fold the long side in half, heat seal the openings on both sides with a small plastic sealing machine, take 10mg of the above synthesized copper terephthalate complex and pour it into the polypropylene film bag, then completely seal the polypropylene film bag and trim the raw edges. Finally, the micro solid phase extraction bags with good sealing performance were cleaned ultrasonically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com