Lithium-ion secondary battery and anode material and manufacturing method thereof

A secondary battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor electrochemical performance and reduced grammage capacity of materials, so as to suppress decomposition reactions, reduce contact interfaces, and prevent gas inflation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

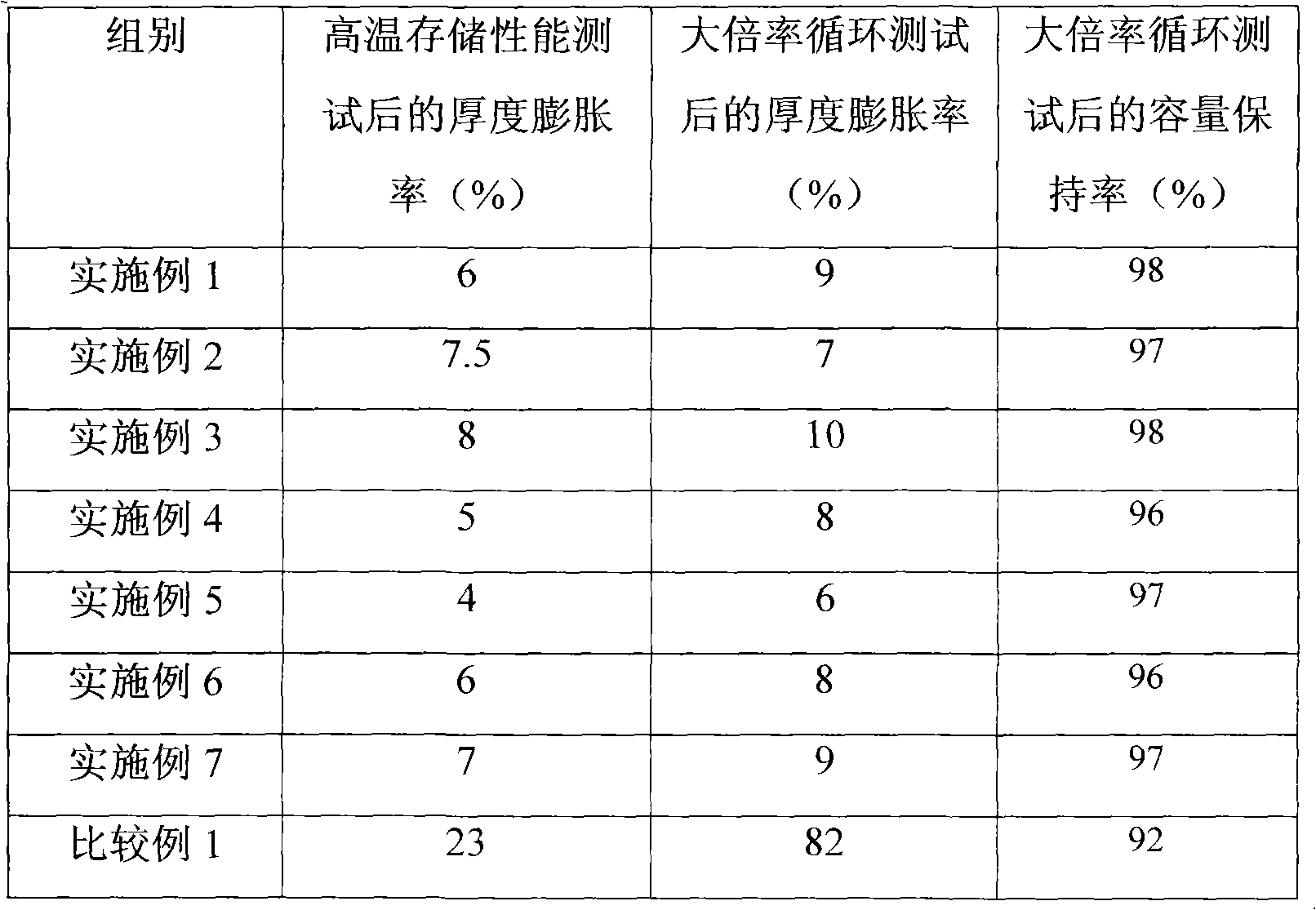

Examples

Embodiment 1

[0034] Preparation of negative electrode material:

[0035] Heat 0.2L of deionized water to 50°C, add a certain amount of 5mol / L reaction auxiliary ammonia water to adjust the pH value between 10.8 and 11.0, and dissolve 13.5g of cobalt sulfate (CoSO 4 ·7H 2 O) and 5.0g zirconium nitrate (Zr(NO 3 ) 4 .5H 2 (2) The mixture is dissolved in deionized water, and is configured into a mixed solution of 1mol / L for subsequent use. After the pH value in the reaction vessel is stable, add 100g lithium titanate (Li 4 Ti 5 O1 2 ) powder; in the reaction process, the NaOH solution of 5mol / L, the ammonia solution of 5mol / L, the mixed solution of cobalt sulfate and zirconium nitrate of 1mol / L are added in the reaction vessel while stirring by peristaltic pump. Control the flow rate of NaOH solution into the reaction vessel to be 3.343mL / min; the flow rate of ammonia solution into the reaction vessel is 0.886mL / min; the flow rate of cobalt sulfate and zirconium nitrate mixed solution i...

Embodiment 2

[0044] Different from Example 1 is the preparation of negative electrode material:

[0045] Heat 0.2L of deionized water to 50°C, add a certain amount of 5mol / L reaction auxiliary ammonia water to adjust the pH value between 10.8 and 11.0, and dissolve 27.0g of cobalt sulfate (CoSO 4 ·7H 2 O) be dissolved in deionized water, and be configured into a mixed solution of 1mol / L for subsequent use. After the pH value in the reaction vessel is stable, add 100g lithium titanate (Li 4 Ti 5 o 12 ) powder; in the reaction process, the NaOH solution of 5mol / L, the ammonia solution of 5mol / L, and the cobalt sulfate solution of 1mol / L were added to the reaction vessel while stirring by a peristaltic pump. Control the flow rate of NaOH solution into the reaction vessel to be 3.343mL / min; the flow rate of ammonia solution into the reaction vessel is 0.886mL / min; the flow rate of cobalt sulfate and zirconium nitrate mixed solution into the reaction vessel is 8.234mL / min. Control the pH v...

Embodiment 3

[0048] Different from Example 1 is the preparation of negative electrode material:

[0049] Heat 0.5L of deionized water to 50°C, add a certain amount of 5mol / L reaction auxiliary ammonia water and 2mol / L CH 3 COOH (oxalic acid) solution adjusts the pH value between 10.8 and 11.0, and 20g of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) and 5.0g magnesium nitrate (Mg(NO 3 ) 2 ·6H 2 (2) The mixture is dissolved in deionized water, and is configured into a mixed solution of 1mol / L for subsequent use. After the pH value in the reaction vessel is stable, add 100g lithium titanate (Li 4 Ti 5 o 12 ) powder; the NaOH solution of 5mol / L, the ammonia solution of 5mol / L, the CH of 2mol / L by peristaltic pump in the reaction process 3 COOH solution, 1mol / L mixed solution of cobalt nitrate and magnesium nitrate were added into the reaction vessel while stirring. The flow rate of NaOH solution added to the reaction vessel was controlled to be 3.343mL / min; the flow rate of ammonia water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com