Electromagnetic forming device and method for manufacturing titanium aluminum-based alloy directional fully-lamellar microstructure

An electromagnetic forming and base alloy technology, applied in the field of material processing, can solve problems such as unfavorable directional growth of columnar crystals, unfavorable control and stable forming, and easy loosening of induction coils, so as to eliminate unstable factors, reduce instability and avoid loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is an electromagnetic forming device for preparing oriented full-lamellar structures of titanium-aluminum-based alloys, including a thermal insulation cover 3 , a forming inductor 5 , a positioning plate 6 , a shielding cover 7 , an insulating plate 8 and clips 4 .

[0049] The shielding cover 7 is placed on the insulating plate 8 located on the upper surface of the water-cooled crystallizer 12 . A positioning plate 6 is placed on the upper surface of the shielding case 7 , and the forming inductor 5 is located on the upper surface of the positioning plate 6 . The thermal insulation cover 3 is located in the inner ring of the shaped inductor 5 . Four clips 4 are placed on the outer circumferential surface of the forming inductor in a cross-symmetrical manner, and at the same time, the lower surface of the horizontal plate of the clip is closely attached to the upper surface of the forming inductor, and connected to the flange 10 of the water-cooled cryst...

Embodiment 2

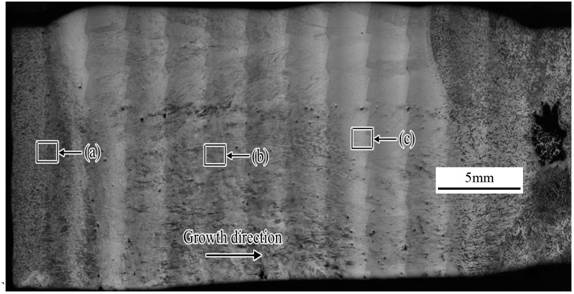

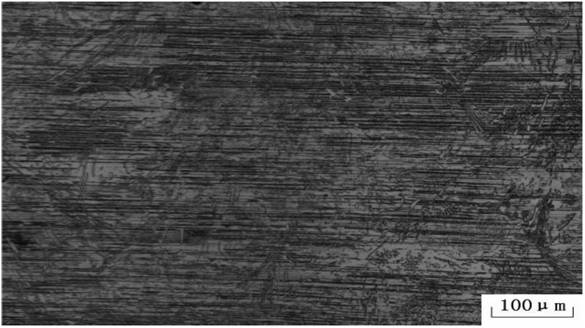

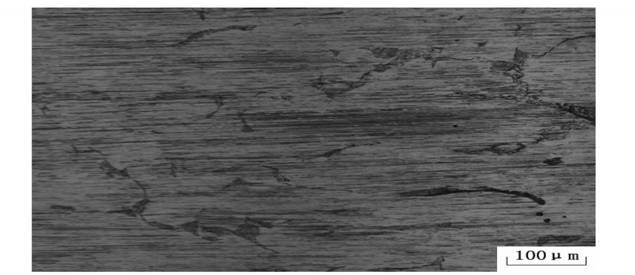

[0069] This embodiment is a method for preparing the oriented full-lamellar structure of a Ti-47Al sample by using the electromagnetic forming device for preparing the oriented full-lamellar structure of a titanium-aluminum-based alloy.

[0070] The first step is to install the seed crystal. A seed crystal 11 with a composition of Ti-43Al-3Si and a diameter of 12 mm is fixed on a drawing rod in a vacuum chamber.

[0071] The second step is to install the base material. Fix the base material 1 with a composition of Ti-47Al and a diameter of 12mm on the synchronization rod in the vacuum chamber, and ensure that the seed crystal 11, the base material 1, the insulation cover 3, the forming inductor 5, the shielding cover 7 and the pull rod are coaxial , while ensuring that the gap between the lower end surface of the base metal 1 and the upper end surface of the seed crystal 11 is 1-3 mm, and the gap between the lower end surface of the base metal 1 and the upper end surface of t...

Embodiment 3

[0077] This embodiment is a method for preparing the oriented full-lamellar structure of a Ti-48Al-8Nb sample by using the electromagnetic forming device for preparing the oriented full-lamellar structure of the titanium-aluminum-based alloy.

[0078] The first step is to install the seed crystal. A seed crystal 11 with a composition of Ti-43Al-3Si and a diameter of 12 mm is fixed on a drawing rod in a vacuum chamber.

[0079] The second step is to install the base material. Fix the base material 1 with a composition of Ti-48Al-8Nb and a diameter of 12mm on the synchronization rod in the vacuum chamber, and ensure that the seed crystal 11, the base material 1, the insulation cover 3, the forming inductor 5, the shielding cover 7 and the pull rod coaxial, and at the same time ensure that the gap between the lower end surface of the base metal 1 and the upper end surface of the seed crystal 11 is 1-3 mm. In this embodiment, the gap between the lower end surface of the base meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com