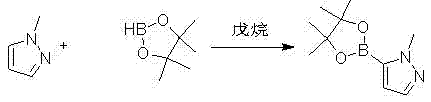

Synthetic method of 1-methyl 4-pyrazole pinacol ester

A synthesis method and pinacol ester technology are applied in the field of preparation of 1-methyl 4-pyrazole pinacol ester, can solve problems such as being limited to laboratory preparation and cannot be produced on a large scale, and achieve process improvement and optimization. The effect of processing technology and raw materials is cheap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1: Under mechanical stirring, add (1.22mol, 100g) SM and 2L anhydrous tetrahydrofuran into the three-necked flask, and cool the solution to -60~-70 o C, slowly add (1.34 mol, 535mL) n-butyllithium (2.5M n-hexane solution) dropwise, and control the dropping temperature not to exceed -60 o C, after the addition is completed at -60~-70 o C reacted for 3 hours, slowly added (1.34 mol, 252g) triisopropyl borate dropwise to the reaction solution, and controlled the dropping temperature not to exceed -60 o C, continue at -60~-70 o C reacted for 3h, slowly warming up to room temperature, reacted at room temperature for 12h, and took a sample to detect that the reaction was qualified. Cool down to 0~10 o C, 2L of saturated ammonium chloride aqueous solution was added dropwise to the reaction solution, the pH was adjusted to 5 with 2N hydrochloric acid solution, and the layers were separated. The aqueous layer was extracted three times with 2 L of ethyl acetate, and the ...

Embodiment 2

[0022] Step 1: Under mechanical stirring, add (1.22mol, 100g) SM and 2L anhydrous tetrahydrofuran into the three-necked flask, and cool the solution to -60~-70 o C. Slowly add (1.46mol, 585mL) n-butyl lithium (2.5M) dropwise, and control the dropping temperature not to exceed -60 o C, after the addition is completed at -60~-70 o C reacted for 2.5h, slowly added (1.34 mol, 252g) triisopropyl borate dropwise to the reaction solution, and controlled the dropping temperature not to exceed -60 o C, continue at -60~-70 o C reacted for 2.5h, slowly warming up to room temperature, reacted at room temperature for 10h, and took a sample to detect that the reaction was qualified. Cool down to 0~10 o C, 2L of saturated ammonium chloride aqueous solution was added dropwise to the reaction solution, the pH was adjusted to 5 with 2N hydrochloric acid solution, and the layers were separated. The aqueous layer was extracted three times with 2 L of ethyl acetate, and the organic layers were...

Embodiment 3

[0025] Step 1: Under mechanical stirring, add (1.22mol, 100g) SM and 2L anhydrous tetrahydrofuran into the three-necked flask, and cool the solution to -60~-70 o C, slowly add (1.34 mol, 535mL) n-butyllithium (2.5M) dropwise, and control the dropping temperature not to exceed -60 o C, after the addition is completed at -60~-70 o C reacted for 3 hours, slowly added (1.34 mol, 252g) triisopropyl borate dropwise to the reaction solution, and controlled the dropping temperature not to exceed -60 o C, continue at -60~-70 o C reacted for 3 hours, slowly warming up to room temperature, reacted for 12 hours at room temperature, and took a sample to detect that the reaction was qualified. Cool down to 0~10 o C, 2L of saturated ammonium chloride aqueous solution was added dropwise to the reaction solution, the pH was adjusted to 6 with 2N hydrochloric acid solution, and the layers were allowed to stand. The aqueous layer was extracted three times with 2 L of ethyl acetate, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com