Method for comprehensively drying liquid rubber and drying device

A liquid rubber and drying device technology, applied in separation methods, chemical instruments and methods, evaporation, etc., can solve the problems of affecting solvent evaporation efficiency, short residence time, small changes in physical properties and appearance, etc., to improve drying efficiency and throughput , reduce residence time, avoid performance and appearance changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The rubber solution to be dried is an isoprene liquid rubber cyclohexane solution containing an anti-aging agent with a weight concentration of 10%, a molecular weight of 30,000, and a molecular weight distribution of 1.07.

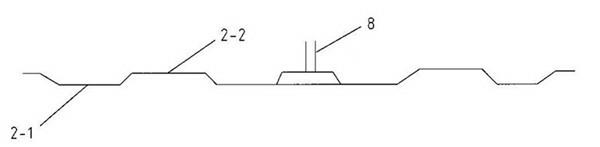

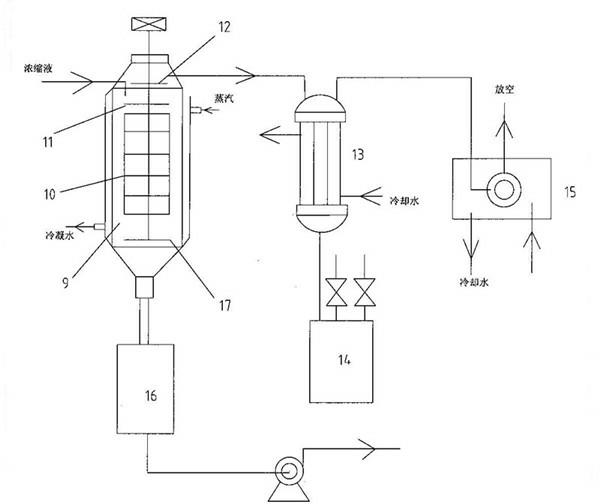

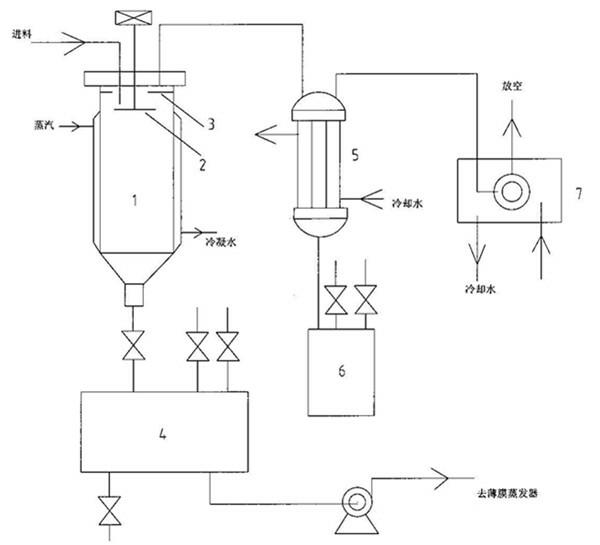

[0023] (1) The rubber solution to be dried enters step (1) at a speed of 800L / h figure 1 The concentrator 1 in the concentrator has a concentrated distributor and a concentrated demister, and the concentrated distributor 2 installed on the stirring shaft 8 is a disc with a concentric groove 2-1 and a raised structure 2-2, The grooves are used for liquid delivery, and the rising solvent ventilation holes are evenly distributed on the raised structure plane, and the rotation speed of the stirring shaft 8 is 300r / min. The concentrator 1 has a jacket, and the concentrator is heated by steam, and the system is evacuated to -50kPa by the concentrator vacuum pump 7, and the temperature in the concentrator is 80°C. The isoprene liquid rubber solution ...

Embodiment 2

[0031] According to the method of embodiment 1, the weight concentration that just needs to be dried rubber solution to change to contain antioxidant is 10%, and molecular weight is 30500, and molecular weight distribution is the butadiene liquid rubber cyclohexane solution of 1.10, and the obtained liquid polybutadiene The volatile content of the rubber is 0.07% by weight, the appearance is nearly colorless and transparent, the number average molecular weight is 30400, and the molecular weight distribution index is 1.11. The obtained liquid polyisoprene rubber had a viscosity of about 75 Pa·s at 38°C.

Embodiment 3

[0033] According to the method of Example 1, only the rubber solution to be dried is replaced with an anti-aging agent with a weight concentration of 10%, a molecular weight of 31100, and a molecular weight distribution of 1.12. Isoprene\butadiene (isoprene and butadiene The weight ratio is 50:50) copolymerized liquid rubber hydrogenated gasoline (boiling range is 55-100 ℃) solution, the volatile content of the obtained liquid polybutadiene rubber is 0.08% by weight, the appearance is close to colorless and transparent, and the number average The molecular weight was 31300, and the molecular weight distribution index was 1.12. The obtained liquid polyisoprene rubber had a viscosity of about 80 Pa·s at 38°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com