Pretreatment method for combined detecting on gas chromatograph and mass spectrum of powdered essence

A gas chromatography-mass spectrometry and essence technology, which is applied in the pretreatment field of reverse solid-phase matrix dispersion purification, can solve the problems of many artificial effects, distortion of the aroma of the analysis liquid, and reduction of operation steps, so as to improve the test efficiency, good reproducibility, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

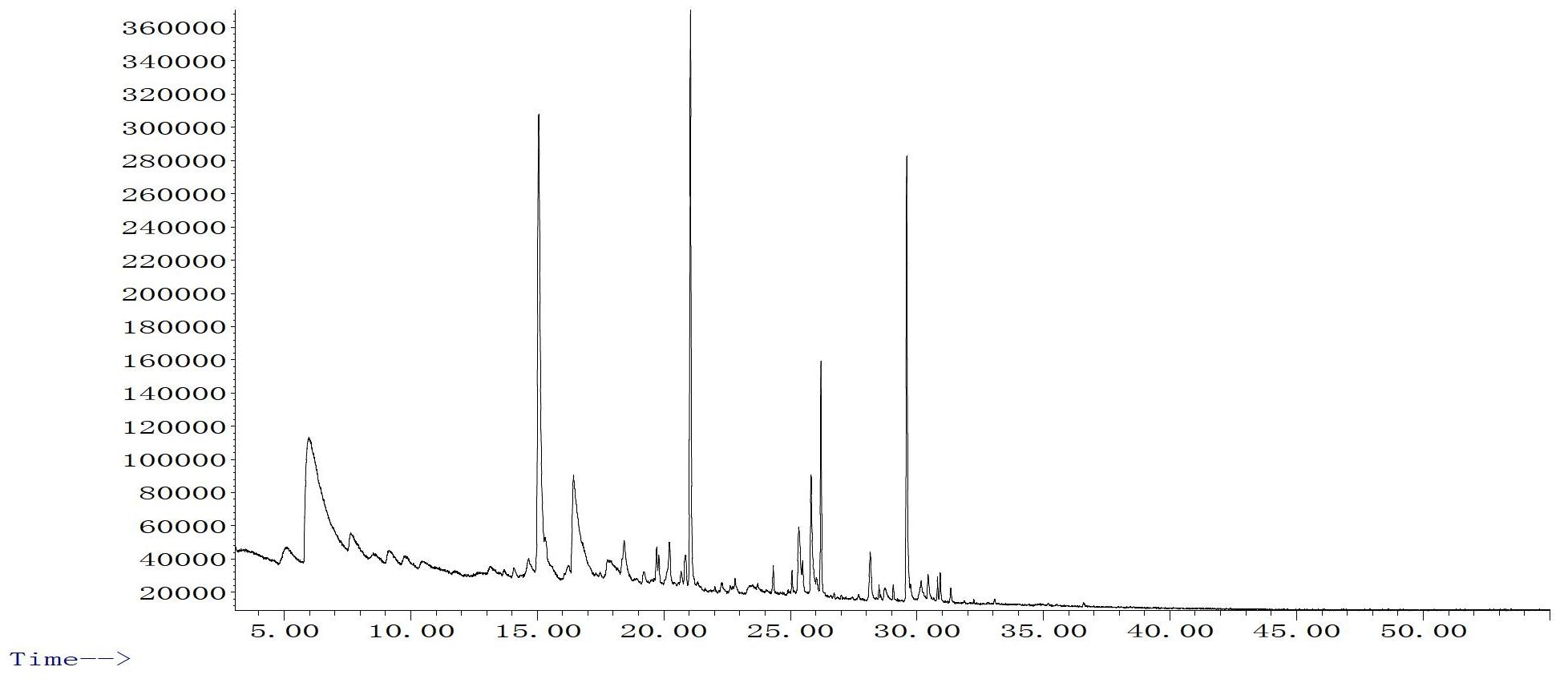

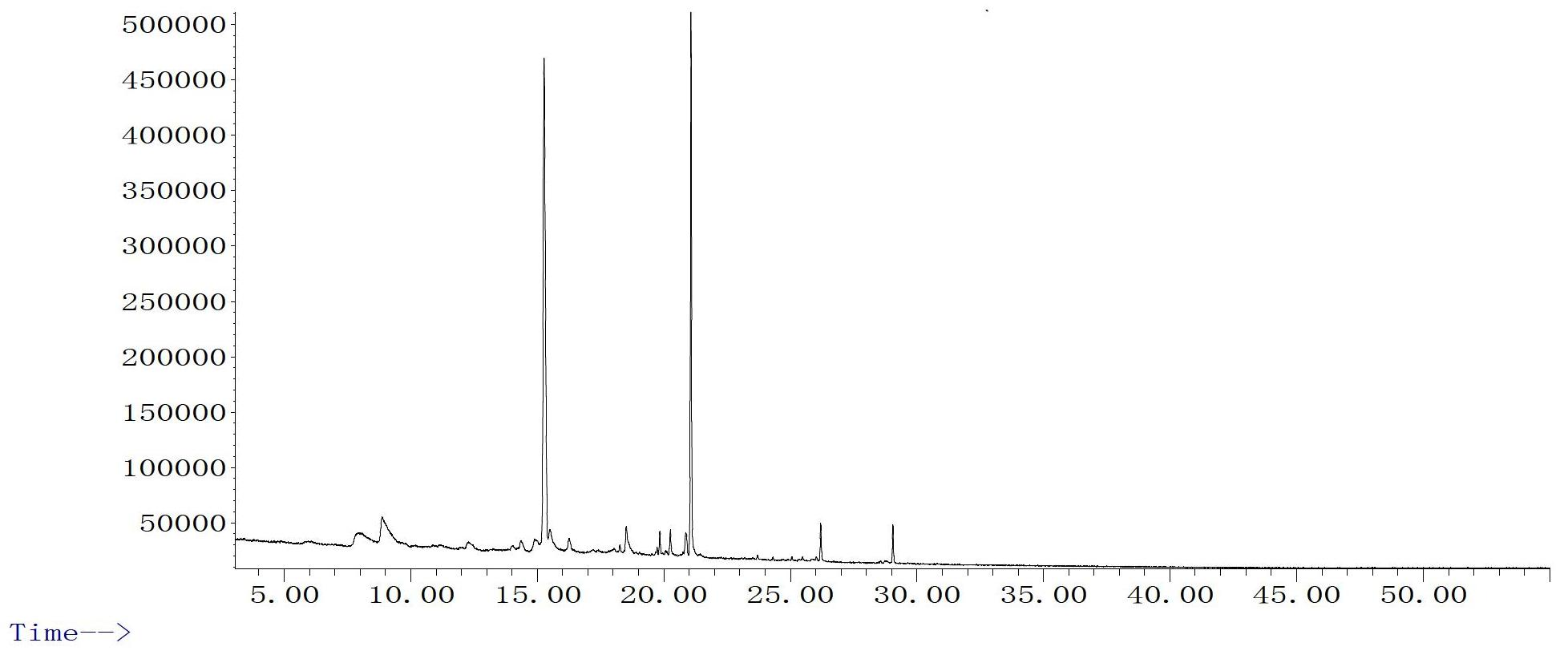

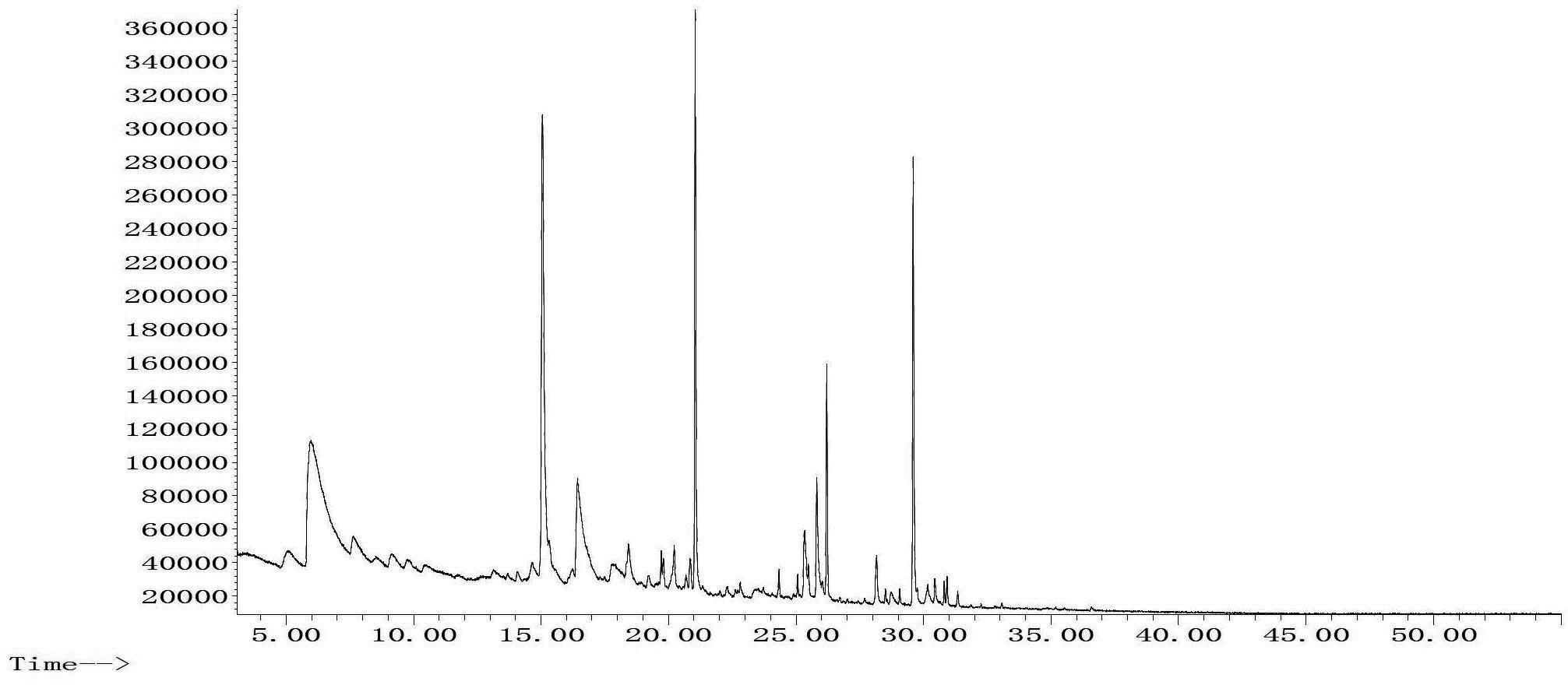

[0020] A reverse solid-phase matrix dispersion purification pretreatment method for detection of powdered flavor by gas chromatography-mass spectrometry, comprising the following steps: after pulverizing and drying the powdery flavor sample, weighing 10 g of the flavor sample into a 50 mL stoppered centrifuge test tube, Add 20g of anhydrous sodium sulfate and vortex stir, after mixing evenly, add 20mL of acetone / n-hexane (v:v=1:1) extract, vortex mix for 2min, then ultrasonically extract for 5min, repeat twice, centrifuge at 3000r / min After removing suspended particles for 10 minutes, take 1 mL of the supernatant in a centrifuge tube, add 50 mg of PSA and 100 mg of anhydrous magnesium sulfate for purification, vortex and mix for 2 minutes, then ultrasonically extract for 5 minutes, then centrifuge at 3000 r / min for 5 minutes, and take 1 μL of the supernatant The fragrance composition was analyzed by gas chromatography-mass spectrometry (GC-MS). GC-MS analysis conditions are: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com