Recovery processing method of cyanide barren solution

A technology of recycling and cyanidation of lean liquid, applied in separation methods, metal cyanide, simple alkali metal cyanide, etc., can solve the problems of large waste residue, high cost, affecting the leaching rate of gold cyanide, etc., to improve the recovery effect , the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

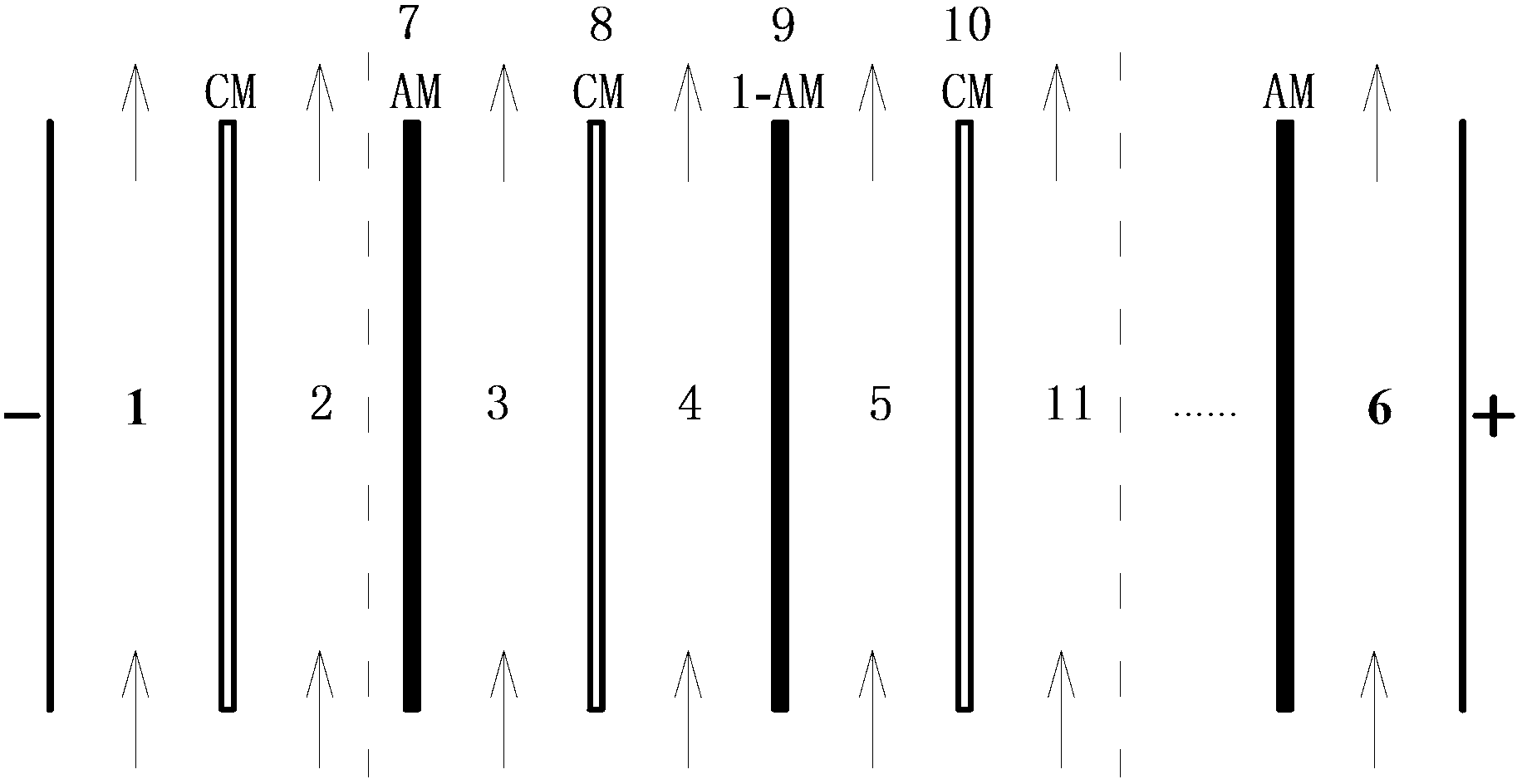

[0017] Adopt the electrodialysis device of six compartment structure in the inventive method, figure 1 1 and 6 are cathode and anode chambers, 2 and 11 are sodium sulfate solution chambers, 3 is metal ion recovery chamber, 4 is feed liquid chamber, 5 is sodium cyanide recovery chamber, 7 is anion exchange membrane (AM), 8 and 10 are cation exchange membranes (CM), and 9 are 1-1 valent anion exchange membranes (1-AM).

[0018] The size of anion and cation exchange membranes is 150×100mm, and the effective membrane area of anion and cation exchange membranes is 88cm 2 , 4 sets of membranes.

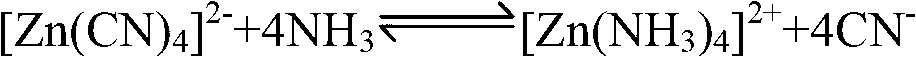

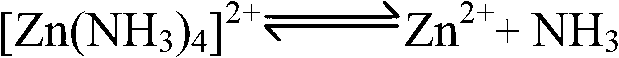

[0019] Take 1000mL of poor cyanide solution and add 10g of ammonia water, the dynamic balance between metal ions and cyanide ions in the solution is destroyed, and ammonia forms complexes with metal ions such as copper and zinc, releasing copper, zinc and other metal cyanide complexes. The cyanide ion CN - ; Then the cyanide barren solution that will add ammoniacal liquor is sent in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com