Method for recycling cyanide from electroplating cyanide-containing wastewater

A technology for cyanide and cyanide wastewater, applied in chemical instruments and methods, water pollutants, separation methods, etc., can solve serious problems, high mass concentration, external water environment pollution, etc., reduce treatment costs, reduce concentrations, and significantly The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

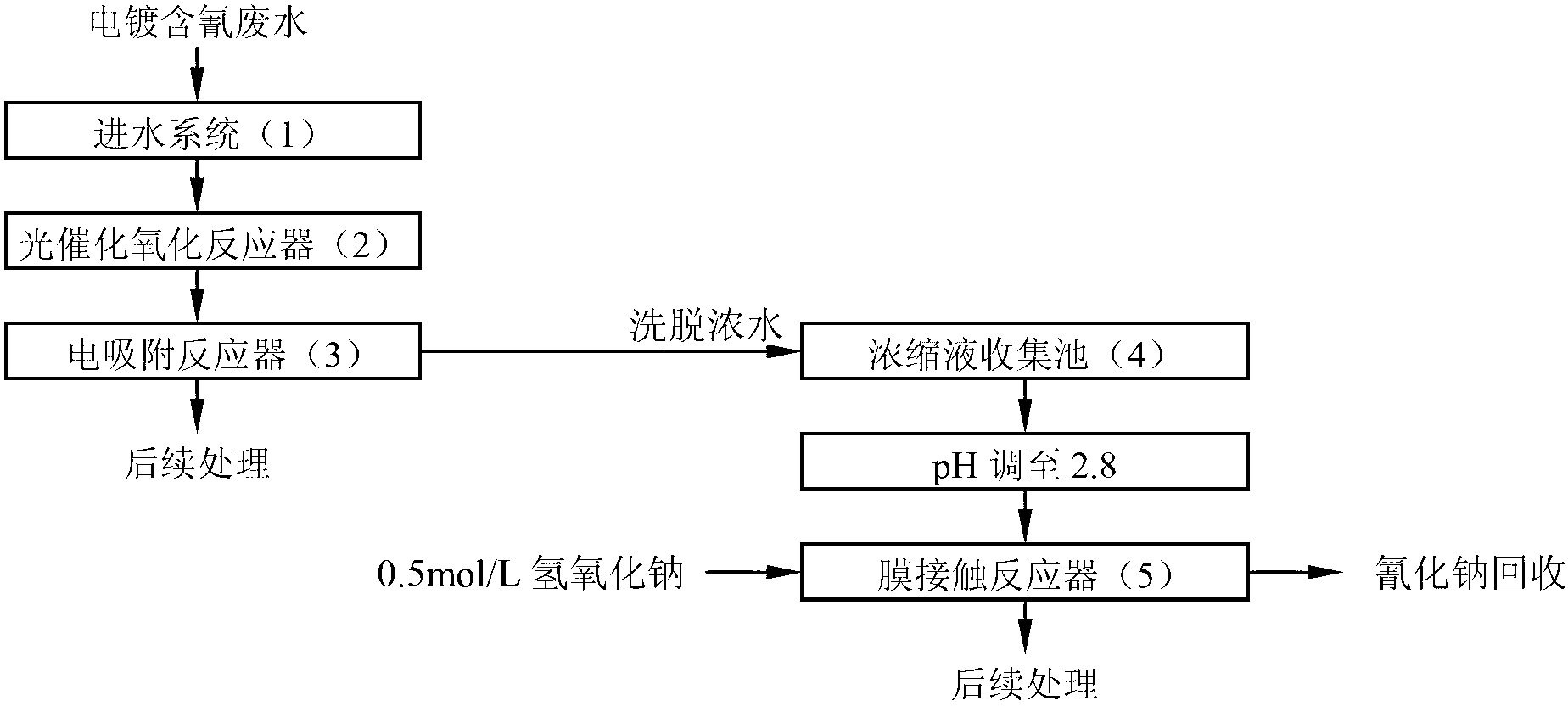

Method used

Image

Examples

Embodiment 1

[0035] The photocatalytic oxidation electro-adsorption membrane contact reactor is used to recover cyanide from electroplating cyanide-containing wastewater. The water quality is as follows: the conductivity is 1200uS / cm, the cyanide ion concentration is 280mg / L, and the pH value is 7.1. The cyanide recovery is carried out for 24 hours.

[0036] Experimental results: After 24 hours of operation, the average removal rate of cyanide is 98.5%, and the equipment operates stably.

Embodiment 2

[0038] The photocatalytic oxidation electro-adsorption membrane contact reactor is used to recover cyanide from electroplating cyanide-containing wastewater. The water quality is as follows: conductivity is 1800uS / cm, cyanide ion concentration is 360mg / L, pH value is 7.3, and cyanide is recovered for 24 hours.

[0039] Experimental results: After 24 hours of operation, the average removal rate of cyanide is 98.2%, and the equipment operates stably.

Embodiment 3

[0041] The photocatalytic oxidation electro-adsorption membrane contact reactor is used to recover cyanide from electroplating cyanide-containing wastewater. The water quality is as follows: the conductivity is 2700uS / cm, the cyanide ion concentration is 640mg / L, and the pH value is 7.0. The cyanide recovery is carried out for 24 hours.

[0042] Experimental results: After 24 hours of operation, the average removal rate of cyanide is 98.8%, and the equipment operates stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com