Modified glutamic acid fertilizer synergist and production method and application thereof

A technology of fertilizer synergist and production method, which is applied in the direction of fertilizer mixture, application, fertilization device, etc., can solve problems such as prolonging the retention time of urea nitrogen, achieve the effects of reducing nutrient loss, wide source of raw materials, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

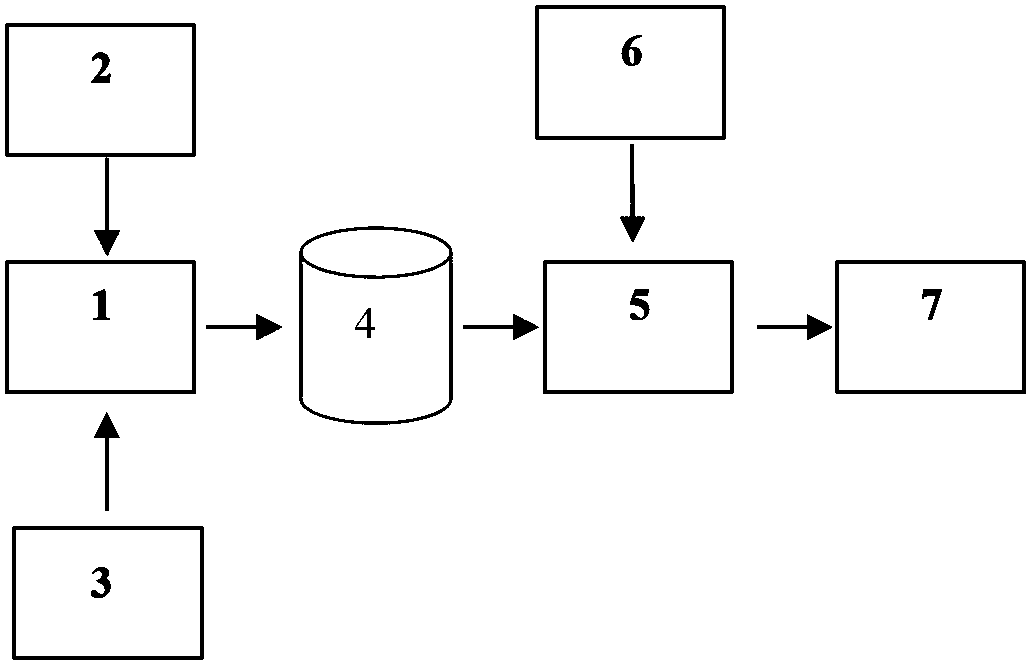

Image

Examples

Embodiment 1

[0054] Embodiment 1: Preparation of modified humic acid fertilizer synergist of the present invention

[0055] A, the weathered coal raw material is pulverized to more than 80 orders, and 10 times of its weight is added to its coal powder, the concentration is 0.3% sodium hydroxide solution by weight and 2 times, the concentration is 5% hydrogen peroxide by weight, Heating and boiling continued for 20 minutes, then cooling and centrifugation to obtain a liquid, which was then heated and concentrated to a solid content of 10% by weight, and this concentrate was humic acid solution A1.

[0056] B, the humic acid solution A1 that obtains with step A is mother liquor, is 4.8gNa according to every liter of mother liquor 2 B 8 o 13 4H 2 O adds Na to the mother liquor 2 B 8 o 13 4H 2 0, obtain humic acid solution A2 after fully dissolving;

[0057] C. Prepare 0.1mol / L EDTA-2Na and ZnSO respectively 4 with MnSO 4 solution, and the solutions were mixed according to the volume...

Embodiment 2

[0059] Embodiment 2: Preparation of modified humic acid fertilizer synergist of the present invention

[0060] A, the raw material lignite is pulverized to 100 mesh, and 9 times of its weight, concentration of 0.5% potassium hydroxide solution and 1 times of concentration of 15% hydrogen peroxide are added to its coal powder, and after heating and continuous boiling for 25 minutes, Then cooling, centrifugation to obtain a liquid, it is heated and concentrated until the solid content therein is 5% by weight, this concentrate is humic acid solution A1.

[0061] B, with the humic acid solution A1 that step A obtains as mother liquor, according to every liter of mother liquor is 7.5gNa 2 B 8 o 13 4H 2 O adds Na to the mother liquor 2 B 8 o 13 4H 2 0, obtain humic acid solution A2 after fully dissolving;

[0062] C. Prepare 0.2mol / L EDTA-2Na and ZnSO respectively 4 with MnSO 4 solution, and the solution is mixed according to the volume ratio of 2:1:1 to obtain the chelate...

Embodiment 3

[0064] Embodiment 3: Preparation of modified humic acid fertilizer synergist of the present invention

[0065] A, the raw material lignite is crushed to 100 mesh, and 8 times of its weight, concentration of 0.1% potassium hydroxide solution and 3 times of concentration of 30% hydrogen peroxide are added to its coal powder, after heating and continuous boiling for 30 minutes, Then cooling, centrifugation to obtain a liquid, it is heated and concentrated until the solid content therein is 15% by weight, this concentrate is humic acid solution A1.

[0066] B, the humic acid solution A1 that obtains with step A is used as mother liquor, is 9.6gNa according to every liter of mother liquor 2 B 8 o 13 4H 2 O adds Na to the mother liquor 2 B 8 o 13 4H 2 0, obtain humic acid solution A2 after fully dissolving;

[0067] C. Prepare 0.3mol / L EDTA-2Na and ZnSO respectively 4 with MnSO 4 solution, and the solution is mixed according to the volume ratio of 2:1:1 to obtain the chela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com