Method for synthesizing modified epoxy acrylate

An epoxy acrylate and synthesis method technology, which is applied in the coating field in the chemical industry, can solve the problems of unstable product performance, poor pigment wettability, cumbersome synthesis method, etc., and achieve excellent yellowing resistance and pigment wettability Good, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

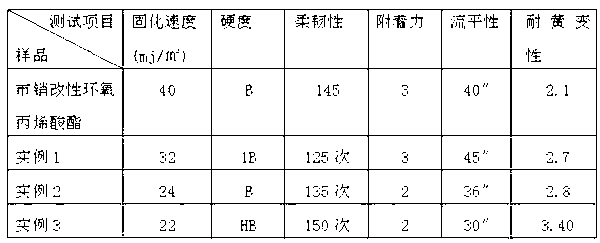

Examples

Embodiment 1

[0022] First, in a four-necked flask equipped with a stirrer, a thermometer, a constant pressure dropping funnel, and a condenser, add 110 g of hydroxyethyl acrylate, 146 g of hexahydrophthalic anhydride, 0.5 g of p-hydroxyanisole, and 1 g of triphenylphosphine. Hypophosphorous acid 0.5g, slowly raise the temperature to keep the material temperature at 95~100°C, keep it warm at this temperature for 2.5 hours, take samples to measure AV, raise the temperature to 105°C and keep it warm until AV≤220. After the AV is qualified, cool down to 100°C, add 200g of epoxy resin, 1g of triphenylphosphine, and 0.5g of p-hydroxyanisole, slowly raise the temperature to 105°C and keep it for 2 hours, then raise the temperature to 110~115°C and keep it for 2 hours, then take a sample to measure AV , until AV≤5. After the AV is qualified, the temperature is lowered to below 95°C, and a benzenetripropylene glycol diacrylate-free 110g , stir evenly, cool down to 80°C, filter and pack with a 100-...

Embodiment 2

[0024] First, in a four-necked flask equipped with a stirrer, a thermometer, a constant pressure dropping funnel, and a condenser, add 110 g of hydroxyethyl acrylate, 144 g of tetrahydrophthalic anhydride, 0.5 g of p-hydroxyanisole, and 1 g of triphenylphosphine. Hypophosphorous acid 0.5g, slowly raise the temperature so that the temperature of the material is 95~100°C, keep it warm at this temperature for 2 hours, take a sample to measure AV, raise the temperature to 105°C and keep it until AV≤220. After the AV is qualified, cool down to 100°C, add 200g of epoxy resin, 1g of triphenylphosphine, and 0.5g of p-hydroxyanisole, slowly raise the temperature to 105°C and keep it for 2 hours, then raise the temperature to 110~115°C and keep it for 2 hours, then take a sample to measure AV , until AV≤5. After the AV is qualified, the temperature is lowered to below 95°C, and a benzenetripropylene glycol diacrylate-free 110g , stir evenly, cool down to 80°C, filter and pack with a 10...

Embodiment 3

[0026] First, in a four-neck flask equipped with a stirrer, a thermometer, a constant pressure dropping funnel, and a condenser, add 115 g of hydroxyethyl acrylate, 144 g of tetrahydrophthalic anhydride, 0.5 g of p-hydroxyanisole, and 1 g of triphenylphosphine. Hypophosphorous acid 0.5g, slowly raise the temperature so that the temperature of the material is 95~100°C, keep it warm at this temperature for 2 hours, take a sample to measure AV, raise the temperature to 105°C and keep it until AV≤220. After the AV is qualified, cool down to 100°C and add 210g of epoxy resin, 1g of triphenylphosphine, 0.5g of p-hydroxyanisole, and 0.5g of hypophosphorous acid, slowly raise the temperature to 105°C for 2 hours, then raise the temperature to 110~115°C for 2 hours Hours, take samples to measure AV until AV≤5. After the AV is qualified, the temperature is lowered to below 95°C, and a benzene-tripropylene glycol diacrylate-free 11 5g , stir evenly, cool down to 80°C, filter and pack wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com