Preparation method of sporoderm-broken spirulina wine

A technology of broken spirulina and brewing method, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of not having the basic elements of natural green food, increasing the production process route, food safety hazards, etc., and achieves obvious health effects and no food Hidden dangers, easy quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

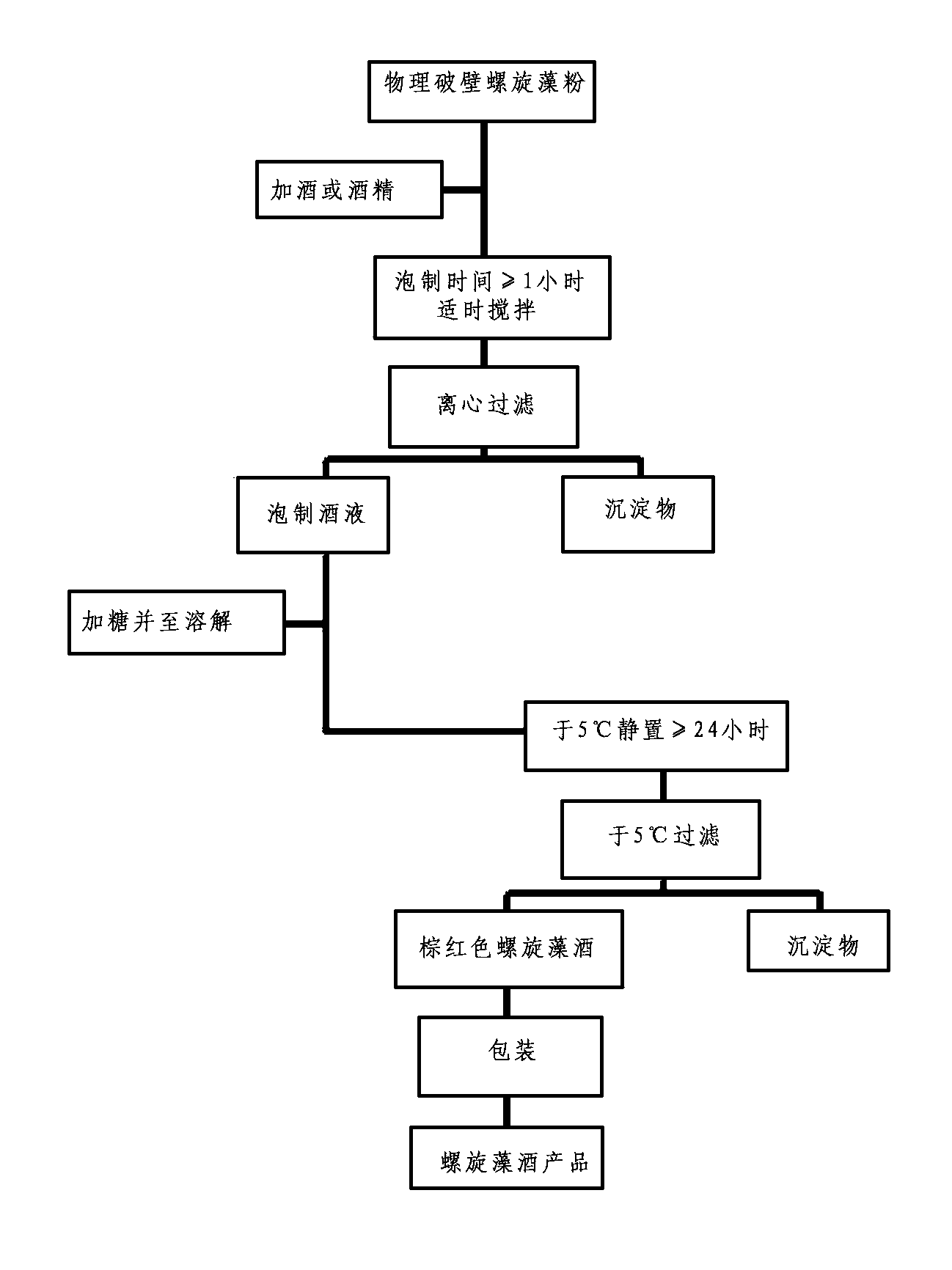

Method used

Image

Examples

example 1

[0011] Example 1: The spirulina powder that has been physically broken is selected, and 60% v / v edible grain wine or edible alcohol is used for brewing. The ratio of broken spirulina to 60% v / v edible wine is: for every 3 kg of broken spirulina add 20 kg of edible grain wine or edible alcohol. Brewing temperature: 50°C, brewing time: ≥1 hour. Use a centrifuge to effectively separate the liquid part from the solid part for the wine that has been brewed. The centrifugal speed is ≥ 1000 rpm, and the centrifugation time is ≥ 5 minutes each time. The liquid obtained by separation is added with edible sugar according to the mass ratio of 3-5%, and stirred in time to dissolve the sugar completely. The liquid is brownish red and has a special fragrance of spirulina protein. This liquid needs to stand at 5°C for ≥24 hours, and then filter at 5°C to remove the precipitate and obtain a transparent and clear liquid. This transparent clear liquid is exactly the spirulina wine indicated...

example 2

[0012] Example 2: The spirulina powder that has been physically broken is selected, and 30% v / v edible grain wine or edible alcohol is used for brewing. The ratio of broken spirulina to 30% v / v edible wine is: add 10 kg of edible grain wine or edible alcohol to every 1 kg of broken spirulina. The brewing temperature is: 40°C, and the brewing time is: 3 hours. Use a centrifuge to effectively separate the liquid part from the solid part for the wine that has been brewed. The centrifugal speed is ≥ 1000 rpm, and the centrifugation time is ≥ 5 minutes each time. The liquid obtained by separation is added with edible sugar according to the mass ratio of 3-5%, and stirred in time to dissolve the sugar completely. The liquid is brownish red and has a special fragrance of spirulina protein. The liquid needs to stand at 5°C for 35 hours, and then filtered at 5°C to remove the precipitate and obtain a transparent and clear liquid. This transparent clear liquid is exactly the spiruli...

example 3

[0013] Example 3: The spirulina powder that has been physically broken is selected, and 50% v / v edible grain wine or edible alcohol is used for brewing. The proportion of broken spirulina and 50% v / v edible wine is: for every 2 kg of broken spirulina, 15 kg of edible grain wine or edible alcohol. The brewing temperature is: 25°C, and the brewing time is: 10 hours. Centrifuge the brewed liquor to effectively separate the liquid part from the solid part. Centrifugal speed ≥ 1000 rpm, each centrifugation time ≥ 5 minutes. Add edible sugar to the liquid separated by the centrifuge according to the mass ratio of 3~5%, and stir it in time to let the sugar dissolve completely. The liquid is brownish-red and has a special aroma of spirulina protein, which needs to be kept at 5°C for 40 hours. This liquid also needs to be filtered at 5°C to remove the sediment and obtain a transparent and clear liquid, which is the spirulina wine indicated by this method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com