Copper plate card and preparation method thereof

A copper plate card and primer coating technology, which is applied in the direction of adding inorganic compounds, water-repellent agents, reinforcing agents, etc., can solve the problems that paper is difficult to meet customer requirements, and achieve excellent performance, good folding resistance, and consistent ink absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

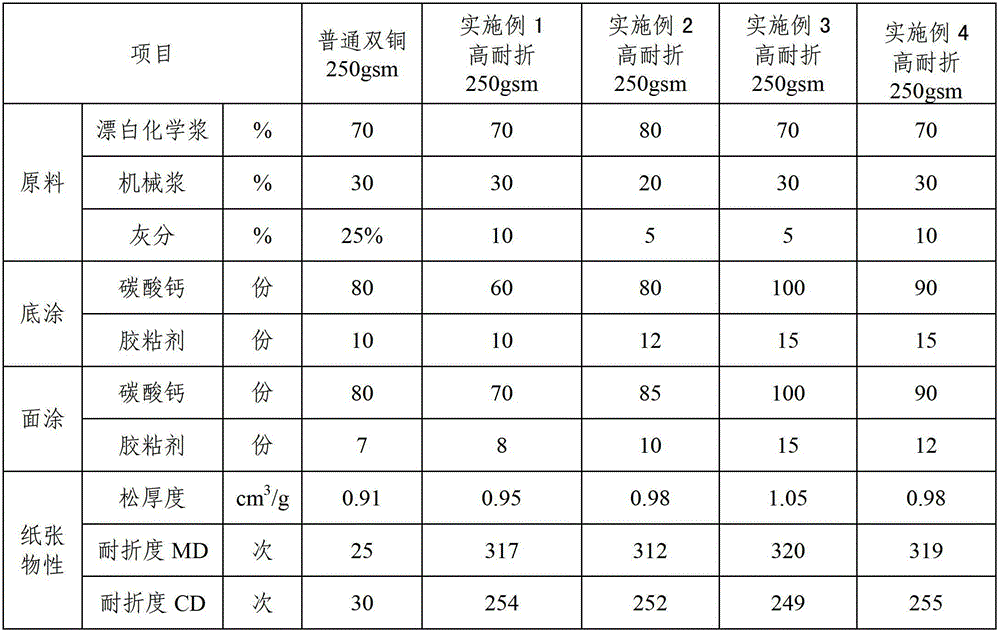

Embodiment 1

[0024] The proportion of pulp is softwood pulp (NBKP, purchased from Jinguang APP Group) 20%, hardwood pulp (LBKP, purchased from Jinguang APP Group) 50%, chemical thermomechanical pulp (BCTMP, purchased from Canada Meadow Lake pulp mill) )30%. The base paper layer uses more softwood pulp (NBKP), which can meet the base paper with higher folding resistance requirements. According to the calculation of 1 ton of paper per 0.9 tons of pulp, the raw materials are dispersed and refined in proportion, and wet-end chemicals (alkyl ketene dimer 7kg / t, alkenyl succinic anhydride 1.0kg / t, positive starch 10kg / t, polyacrylamide ternary retention system, fluorescent whitening agent 2kg / t, polyaluminum chloride 0.7kg / t), sizing, dehydration, front drying, surface sizing, post drying, curling into paper, and making base paper .

[0025] The dust point of base paper is controlled below 0-5ppm to meet the basic requirements for the appearance of high-grade paper in the international market...

Embodiment 2

[0033] The proportion of pulp is 30% of softwood pulp (NBKP), 50% of hardwood pulp (LBKP), and 20% of chemithermomechanical pulp (BCTMP). According to the calculation of 1 ton of paper per 0.95 tons of pulp, the raw materials are dispersed, refined, and wet-end chemicals are added in proportion (5 kg / t of alkyl ketene dimer, 08 kg / t of alkenyl succinic anhydride, 8 kg / t of positive starch) t, polyacrylamide ternary retention system, polyaluminum chloride 0.5kg / t), sizing, dehydration, pre-drying, surface sizing, post-drying, curling into paper, and making base paper.

[0034]The dust point of base paper is controlled below 0-5ppm to meet the basic requirements for the appearance of high-grade paper in the international market. The paper weight of the base paper is 100-200gsm, the ash content of the base paper is controlled at 5% or less, and a three-way retention system (cationic polyacrylamide 0.2kg / t, anionic polyacrylamide 0.2kg / t, weak anionic polyacrylamide 2.0 kg / t), th...

Embodiment 3

[0039] The proportion of pulp is 25% of softwood pulp (NBKP), 45% of hardwood pulp (LBKP), and 30% of chemical thermomechanical pulp (BCTMP). According to the calculation of 1 ton of paper per 0.95 tons of pulp, the raw materials are dispersed, refined, and wet-end chemicals are added in proportion (10kg / t of alkyl ketene dimer, 1.2kg / t of alkenyl succinic anhydride, 12kg of positive starch / t, polyacrylamide ternary retention system, fluorescent whitening agent 5kg / t, polyaluminum chloride 1kg / t), sizing, dehydration, pre-drying, surface sizing, post-drying, curling into paper, and make base paper.

[0040] The dust point of base paper is controlled below 0-5ppm to meet the basic requirements for the appearance of high-grade paper in the international market. The grammage of base paper is 100-300gsm, the ash content of base paper is controlled at 5% or less, and a ternary retention system (cationic polyacrylamide 0.2kg / t, anionic polyacrylamide 0.2kg / t, weak anionic polyacryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com