Method for preparing transmission electron microscope sample of rust layer powder test sample

A transmission electron microscope sample and rust layer technology, which is applied in the preparation of test samples, material analysis by measuring secondary emissions, etc., can solve the problems of unsuitable rust layer powder sample preparation, long drying time of samples, and inability to truly respond, etc. problems, achieve the effect of shortening the sample preparation cycle, not easy to decompose and break, and easy to observe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] 1) Scrape off the rust layer from the surface of the steel sample with a blade and grind it into powder;

[0028] 2) Mix a small amount of rust layer powder into the collodion and isoamyl acetate solution, wherein the collodion and isoamyl acetate solution is 5% by mass of the collodion solution and isoamyl acetate according to the mass ratio = 1:2 mixed;

[0029] 3) Add some deionized water into the petri dish, use a dropper to absorb the above mixed solution, and drop a drop on the water. Due to the surface tension, the mixed solution spreads rapidly to form a thin film. Mix the solution together to form a layer of organic film on the electron microscope grid;

[0030] 4) After putting the electron microscope grid with the rust layer powder attached in a drying oven to dry, use a vacuum coating machine to spray carbon on the surface of the electron microscope grid to obtain a rust layer sample for transmission electron microscope observation.

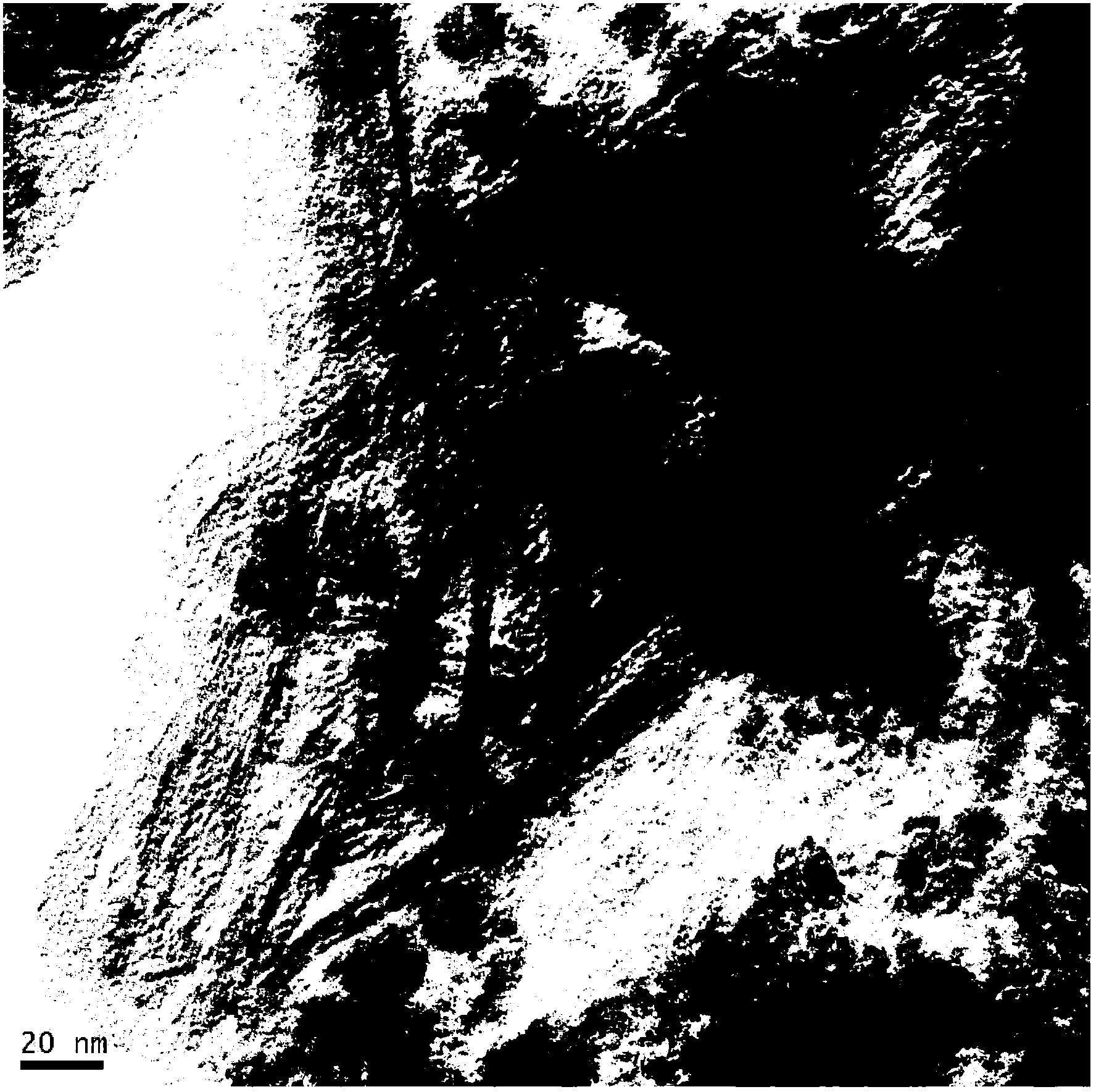

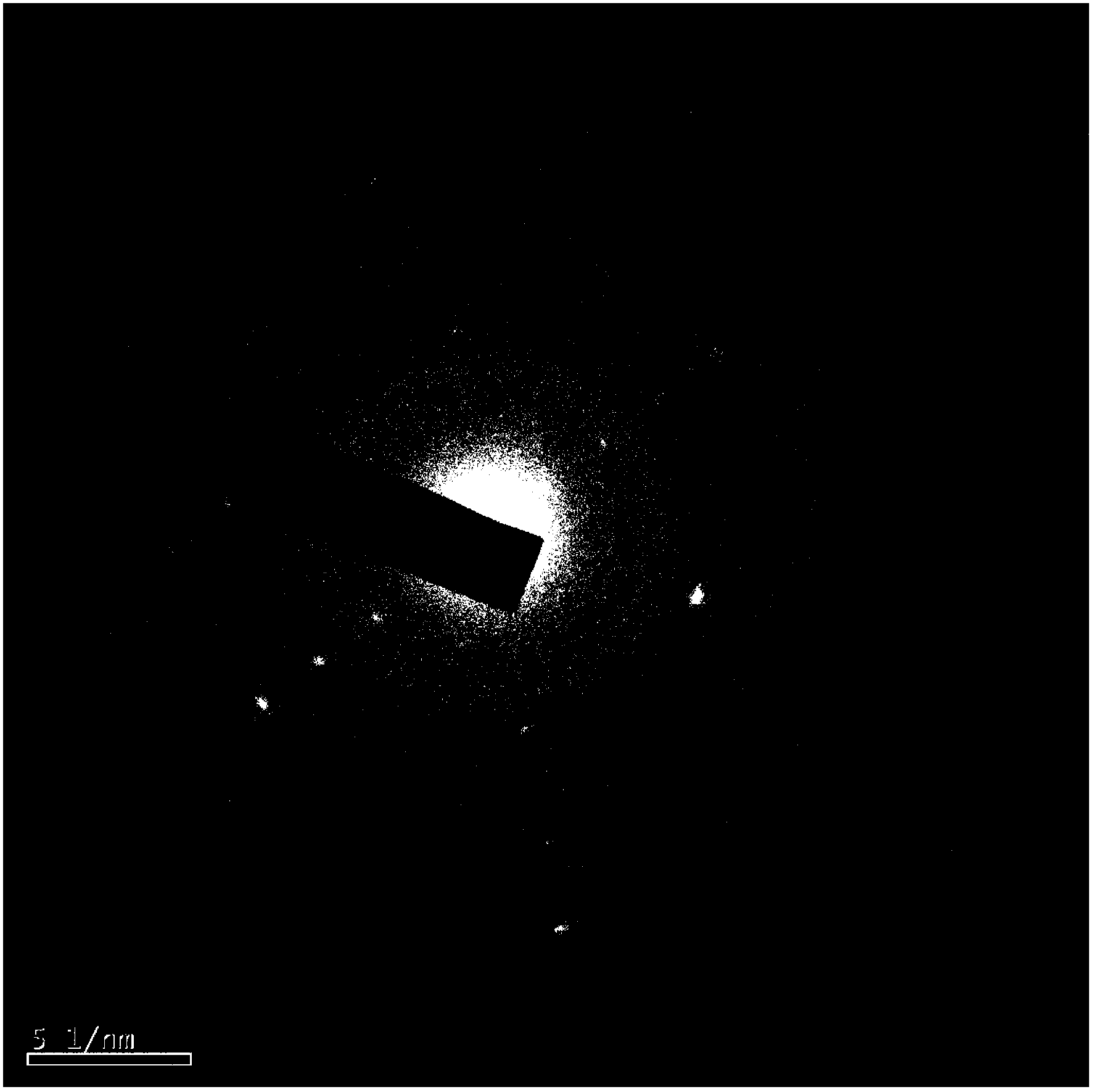

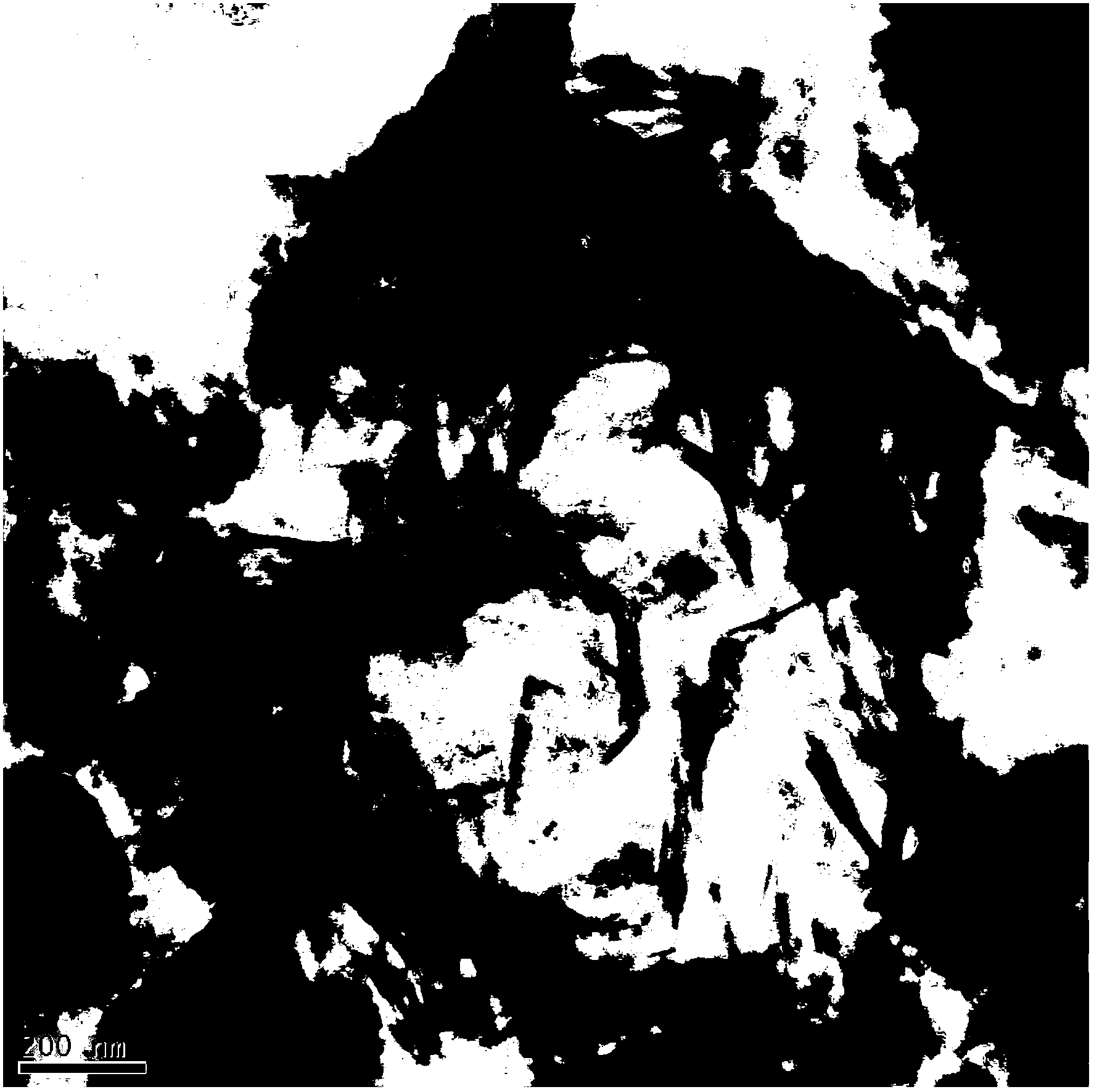

[0031] The rust layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com