Chemical analysis method of rhodium content

A technology of rhodium content and silicon dioxide, applied in the field of chemical analysis, can solve the problems of unreported analysis method, long process flow, complicated operation steps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

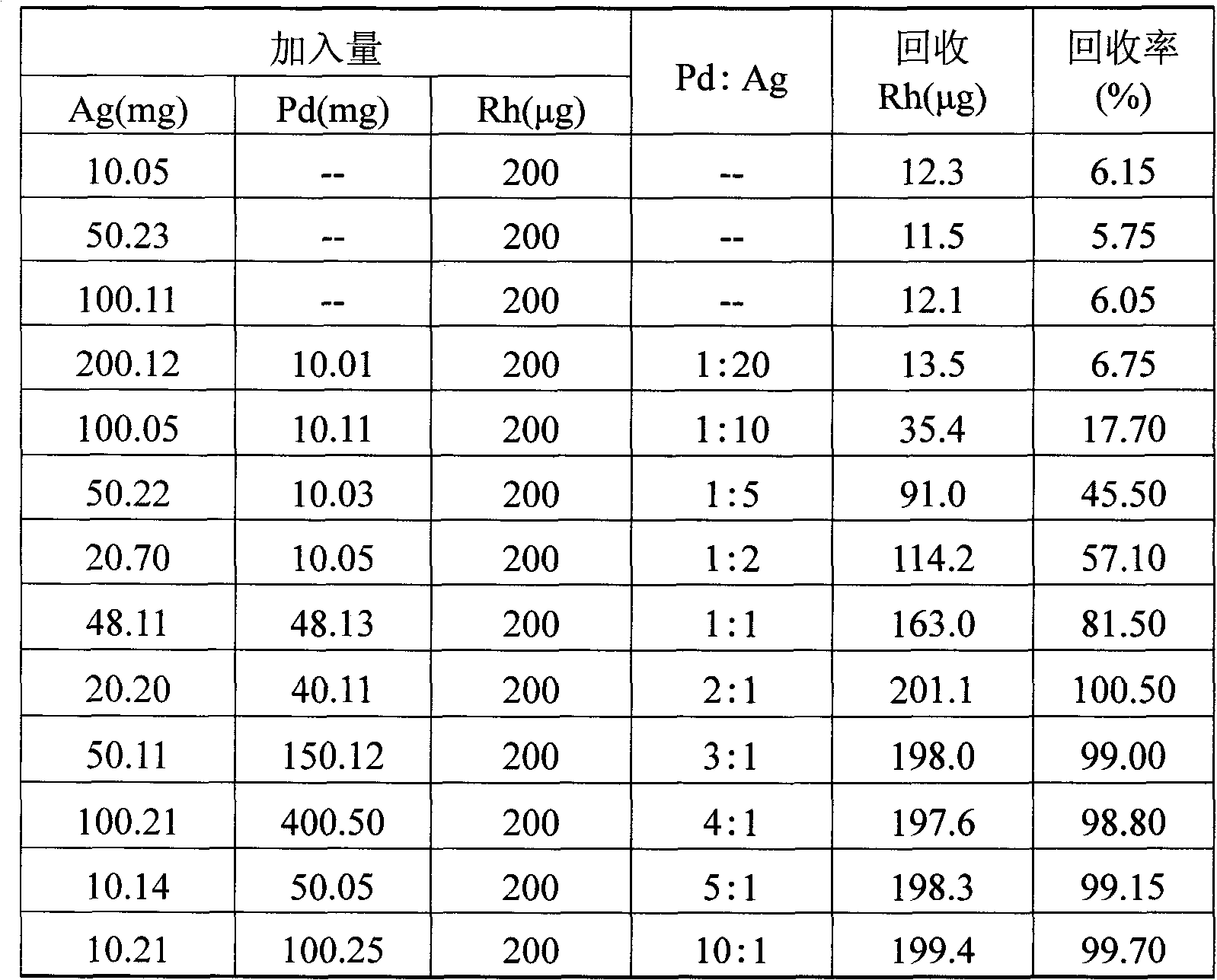

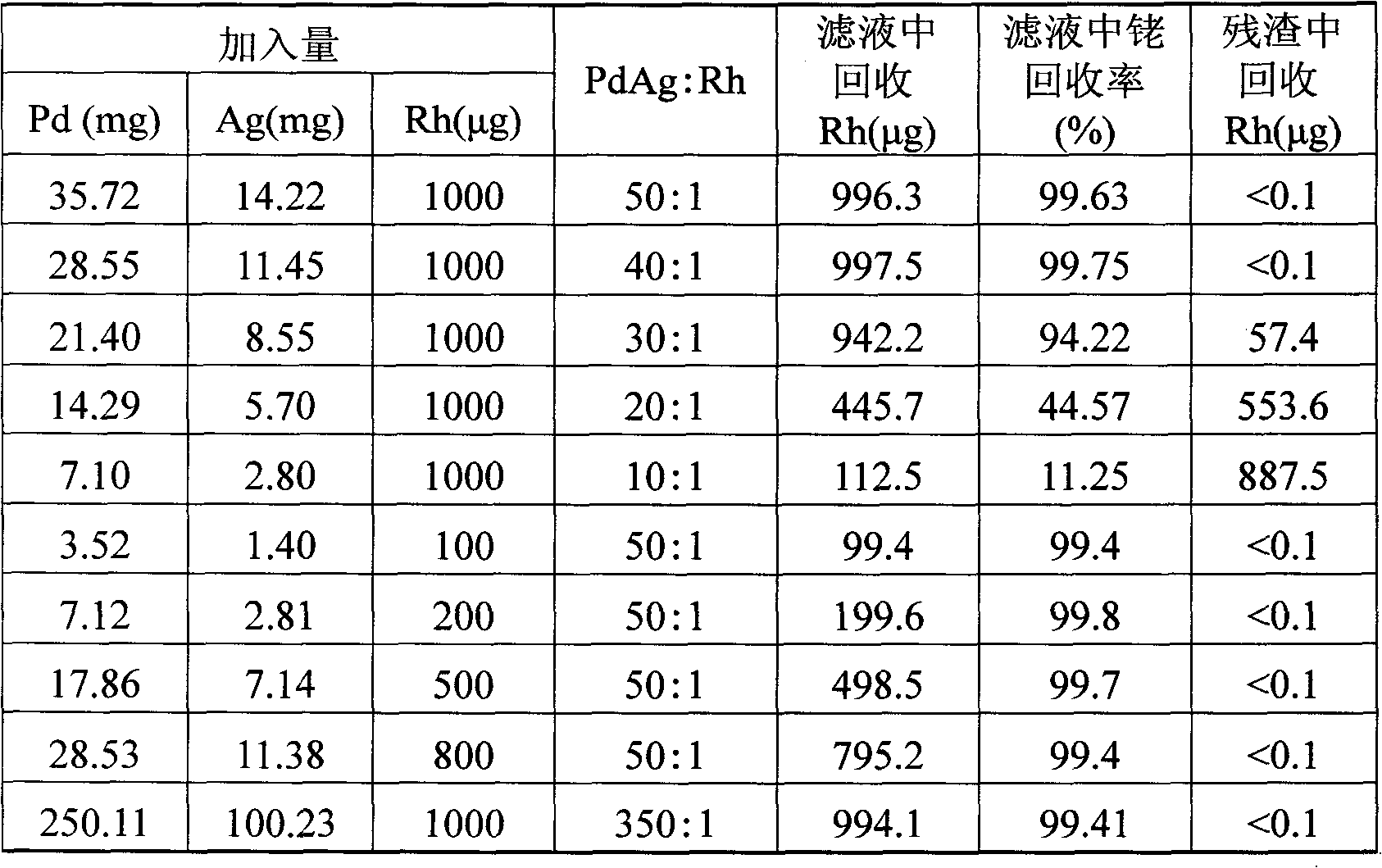

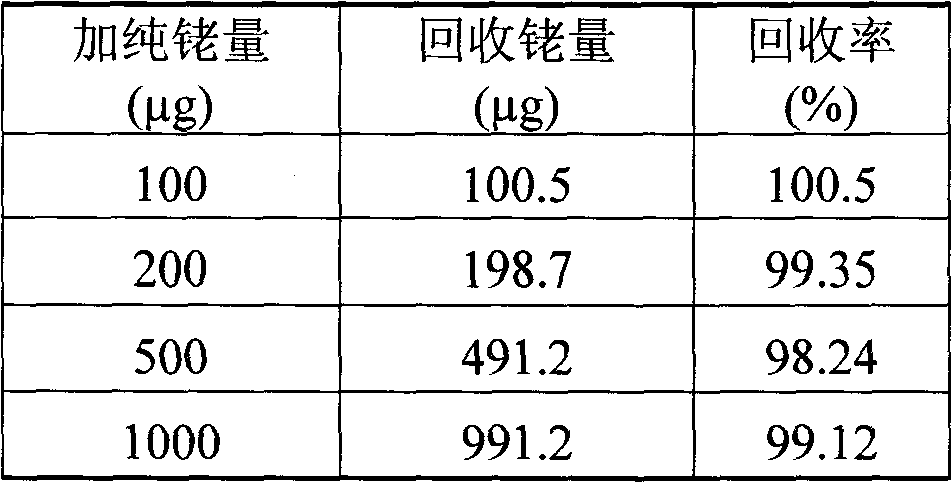

Method used

Image

Examples

Embodiment 1

[0038] Weigh 0.5002g of 1# catalyst, add 20g of anhydrous sodium carbonate, 10g of borax, 9g of silicon dioxide, 3.2g of flour and 80g of lead oxide, weigh 5mg of silver powder and 15mg of sponge palladium powder as ash blowing protection agent, mix well, and transfer to assay gold Crucible, put the crucible into the gold assay furnace whose temperature has been raised to 800°C, close the furnace door, quickly raise the temperature to 1100°C and keep it warm for 20 minutes, remove the crucible out of the furnace, cool down, take out the lead buckle, put the lead buckle into the Preheat the ash dish for more than 20 minutes in a muffle furnace at ℃, close the furnace door for 2 minutes, and melt the lead buckle. , take out the ash dish, cool down; put the pellets into a 100mL beaker, add 10mL of 1:3 HNO 3 : water, heating to dissolve, adding 10mL of ρ1.19g / mLHCl, heating, evaporating to 0.5mL, cooling, constant volume in a 100mL volumetric flask, and ICP-AES to measure the rhod...

Embodiment 2

[0040] Weigh 1.5010g of 1# catalyst, add 20g of anhydrous sodium carbonate, 10g of borax, 8g of silicon dioxide, 3.2g of flour and 80g of lead oxide, weigh 10mg of silver powder and 50mg of sponge palladium powder into a mixing bottle, mix well, and transfer to the sample mixing bottle. For the gold crucible, put the crucible into the gold assay furnace whose temperature has been raised to 800°C, close the furnace door, rapidly raise the temperature to 1100°C and keep it warm for 20 minutes, remove the crucible from the furnace, cool down, take out the lead buckle, put the lead buckle into the Preheat the ash dish in a muffle furnace at 920°C for more than 20 minutes, close the furnace door for 2 minutes, and melt the lead buckle. Afterwards, remove the ash dish and let it cool. Put the pellets into a 100mL beaker, add 20mL of 1:3 HNO 3 : water, heating to dissolve, adding 15mL of ρ1.19g / mLHCl, heating, evaporating to 5mL, cooling, constant volume in a 100mL volumetric flask,...

Embodiment 3

[0042]Weigh 10.00g of 2# smelting slag, add 30g of anhydrous sodium carbonate, 10g of borax, 15g of silicon dioxide, 4g of flour and 120g of lead oxide, calculate that the amount of silver contained in the sample is 5.5mg, weigh 100mg of silver powder, and 300mg of sponge palladium powder Put it into the sample mixing bottle, mix it evenly, move it into the assay gold crucible, put the crucible into the assay gold furnace that has been heated to 800°C, close the furnace door, rapidly raise the temperature to 1100°C and keep it warm for 20 minutes, remove the crucible out of the furnace, and cool it down. Take out the lead buckle, put the lead buckle into the ash dish that has been preheated in a muffle furnace at 920°C for more than 20 minutes, close the furnace door for 2 minutes to melt the lead buckle, and after the lead buckle peels off, open the furnace door and lower the furnace temperature to 900°C, continue ash blowing, when the silver beads flash, take out the ash dish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com