Heterojunction solar cell with buried grid structure

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of hydrogenated amorphous silicon attenuation, which has not been well solved, to increase visible light absorption, improve performance, and reduce grids. Effect of Line Shading Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

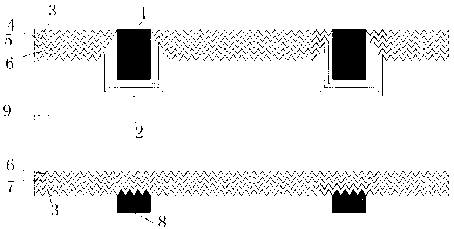

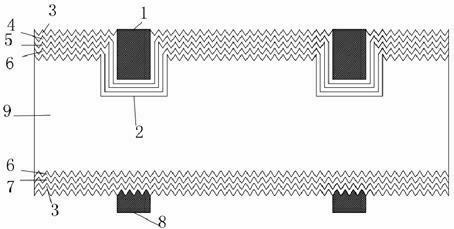

[0015] like figure 1 As shown, a heterojunction solar cell with a buried gate structure includes an N-type single crystal silicon substrate 9, a battery positive electrode 1, a groove 2, an intrinsic hydrogenated nano-silicon film layer 6, a P-type hydrogenated nano-silicon film layer 5, P-type heavily doped hydrogenated nano-silicon carbide film layer 4 , N-type hydrogenated nano-silicon film layer 7 , transparent conductive film 3 , battery negative electrode 8 . The N-type monocrystalline silicon substrate 9 is provided with a groove 2 on the front (main light-receiving surface), and a layer of intrinsic hydrogenated nano-silicon film layer 6, P-type hydrogenated nano-silicon film layer 5 and P-type heavy silicon film layer are sequentially deposited on the front side. Doping hydrogenated nano-silicon carbide film layer 4, and preparing a layer of transparent conductive film 3 on the P-type heavily doped hydrogenated nano-silicon carbide film layer 4; the back of the N-type...

Embodiment 2

[0020] The structure of the heterojunction solar cell with buried gate structure is the same as that in Embodiment 1.

[0021] The preparation method of the buried gate structure heterojunction solar cell in Example 2 is as follows:

[0022] The N-type single crystal silicon substrate 9 used has a thickness of 200 μm and a resistivity of 3Ω·cm. Laser grooves are cut on one side of the N-type single crystal silicon substrate 9 to form grooves 2 with a width of 35 μm and a depth of 18 μm. Then, the grooved N-type single crystal silicon substrate 9 is textured in the mixed solution described in Embodiment 1 to form a pyramid-shaped textured surface. Then, the N-type single crystal silicon substrate 9 after texturing is cleaned and dried by an acid cleaning process, and the surface cleanliness of the silicon wafer is required to be very high. Then use PECVD technology to deposit intrinsic hydrogenated nano-silicon film layer 6 on the front side of N-type single crystal silicon su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com