Negative lead plaster of lead-carbon battery and preparation method thereof, negative polar plate and lead-carbon battery

A lead-carbon battery and negative electrode lead paste technology, applied in negative electrode lead paste and fields, can solve the problems of low hydrogen evolution overpotential, battery water loss, short cycle life of lead-carbon battery, etc. Avoid serious effects of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

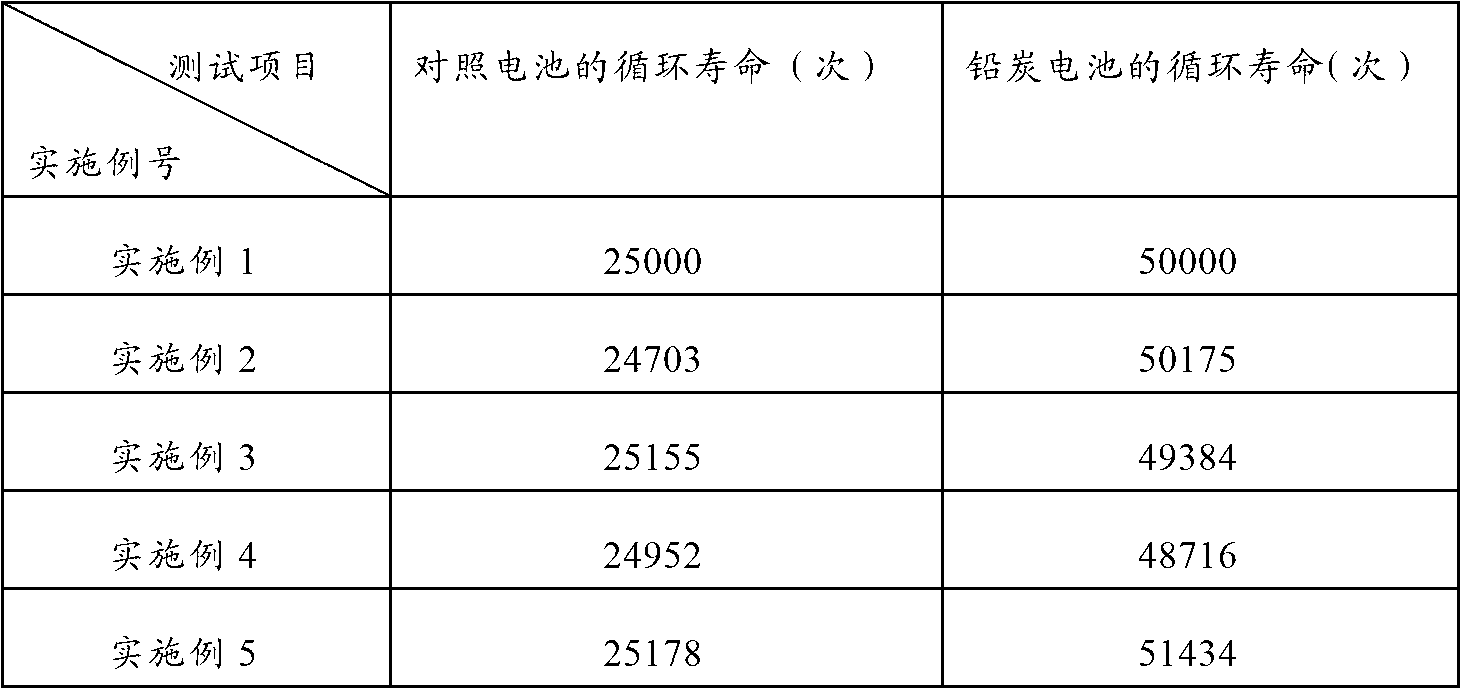

Examples

Embodiment 1

[0028] This embodiment provides a negative electrode paste for a lead-carbon battery and a preparation method thereof.

[0029] 1. The component distribution ratio of the negative electrode paste of the lead-carbon battery

[0030] The component distribution ratio of the negative electrode paste is: lead powder with a degree of oxidation of 72%: 100Kg, sulfuric acid solution with a density of 1.37g / ml: 5Kg, barium sulfate: 0.5Kg, activated carbon: 4Kg, acetylene black: 0.1Kg, graphite Alkene: 0.4Kg, humic acid: 1Kg, polyester fiber with a length of 3mm: 0.1Kg, water: 10Kg, lignin: 0.1Kg, barium stearate 0.5Kg.

[0031] Two, the preparation method of the negative lead paste of lead-carbon battery

[0032] The specific preparation method is as follows:

[0033] Step (1): According to the above weight ratio, put activated carbon, graphene, acetylene black, and barium stearate into a blender and stir for 10 minutes to obtain the first mixture;

[0034] Step (2): According to th...

Embodiment 2

[0064] This embodiment provides a negative electrode paste for a lead-carbon battery and a preparation method thereof.

[0065]1. The component distribution ratio of the negative electrode paste of the lead-carbon battery

[0066] The component distribution ratio of the negative electrode paste is: lead powder with a degree of oxidation of 78%: 100Kg, sulfuric acid solution with a density of 1.45g / ml: 10Kg, barium sulfate: 0.8Kg, activated carbon: 0.1Kg, acetylene black: 1Kg, graphite Alkene: 0.1Kg, humic acid: 4Kg, polyester fiber with a length of 4mm: 1Kg, water: 20Kg, lignin: 2Kg, zinc oxide: 0.1Kg.

[0067] Two, the preparation method of the negative lead paste of lead-carbon battery

[0068] The specific preparation method is as follows:

[0069] Step (1): According to the above weight ratio, put activated carbon, graphene, acetylene black, and barium stearate into a blender and stir for 7 minutes to obtain the first mixture;

[0070] Step (2): According to the above w...

Embodiment 3

[0081] This embodiment provides a negative electrode paste for a lead-carbon battery and a preparation method thereof.

[0082] 1. The component distribution ratio of the negative electrode paste of the lead-carbon battery

[0083] The component distribution ratio of the negative electrode paste is: lead powder with a degree of oxidation of 74%: 100Kg, sulfuric acid solution with a density of 1.41g / ml: 7Kg, barium sulfate: 1Kg, activated carbon: 0.9Kg, acetylene black: 0.3Kg, graphite Alkene: 4Kg, humic acid: 2Kg, polyester fiber with a length of 2mm: 0.5Kg, water: 15Kg, lignin: 0.7Kg, barium stearate: 1Kg, bismuth oxide: 1Kg.

[0084] Two, the preparation method of the negative lead paste of lead-carbon battery

[0085] The specific preparation method is as follows:

[0086] Step (1): According to the above weight ratio, put activated carbon, graphene, acetylene black, and barium stearate into a blender and stir for 9 minutes to obtain the first mixture;

[0087] Step (2):...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com