Silicon-carbon composite material and preparation method thereof

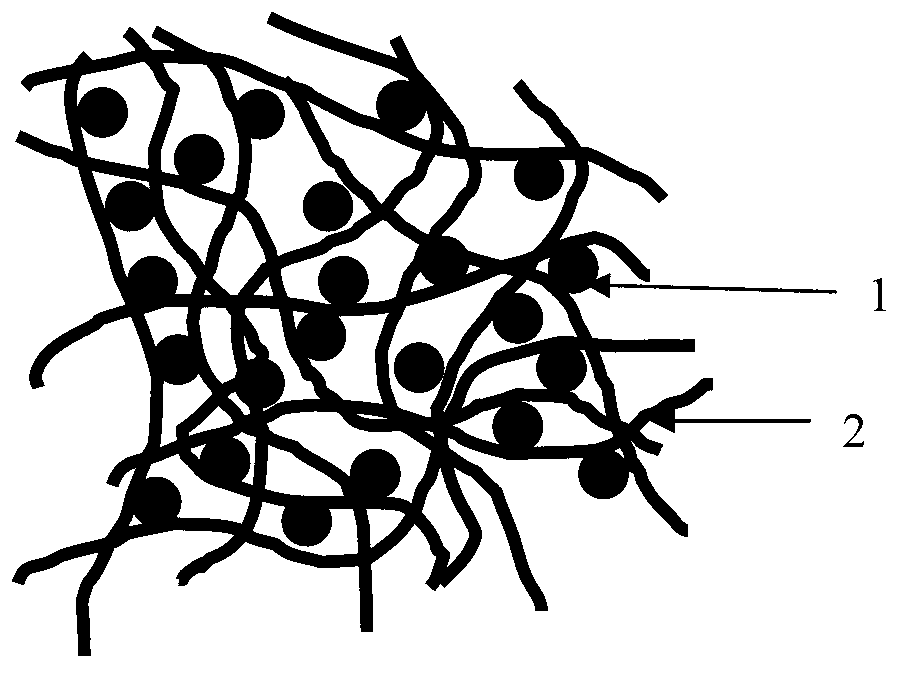

A technology of silicon-carbon composite materials and pastes, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., can solve problems affecting battery cycle stability, carbon layer separation, peeling, electrode pulverization, etc. problem, to achieve the effect of good battery cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Beat the bacterial cellulose with a beater to prepare a uniform bacterial cellulose slurry;

[0039] (2) Take part of the bacterial cellulose slurry, add a certain amount of nano-scale silicon to the bacterial cellulose slurry, and add a certain amount of surfactant Triton-100, and mix evenly to obtain silicon-containing Bacterial cellulose slurry; wherein, the addition of silicon is 10wt.% of bacterial cellulose, and the addition of surfactant is 20wt.% of silicon;

[0040] (3) Pour the bacterial cellulose slurry and the silicon-containing bacterial cellulose slurry into a Buchner funnel for suction filtration and stack them alternately to obtain a silicon-containing bacterial cellulose film; the number of superimposed layers is 5 layers, the uppermost layer and the lowermost layer are all layers of the bacterial cellulose slurry, the thickness of the bacterial cellulose slurry is 0.1mm, and the thickness of the silicon-containing bacterial cellulose slurry layer i...

Embodiment 2

[0045] (1) Beat the bacterial cellulose with a beater to prepare a uniform bacterial cellulose slurry;

[0046] (2) Take part of the bacterial cellulose slurry, add a certain amount of nano-scale silicon to the bacterial cellulose slurry, and add a certain amount of surfactant Triton-100, and mix evenly to obtain silicon-containing Bacterial cellulose slurry; wherein, the addition of silicon is 100wt.% of bacterial cellulose, and the addition of surfactant is 100wt.% of silicon;

[0047] (3) Pour the bacterial cellulose slurry and the silicon-containing bacterial cellulose slurry into a Buchner funnel for suction filtration and stack them alternately to obtain a silicon-containing bacterial cellulose film; the number of superimposed layers is 11 layers, the uppermost layer and the lowermost layer are all layers of the bacterial cellulose slurry, the thickness of the bacterial cellulose slurry is 1mm, and the thickness of the silicon-containing bacterial cellulose slurry layer ...

Embodiment 3

[0052] (1) Beat the bacterial cellulose with a beater to prepare a uniform bacterial cellulose slurry;

[0053] (2) Take part of the bacterial cellulose slurry, add a certain amount of nano-scale silicon to the bacterial cellulose slurry, and add a certain amount of surfactant Triton-100, and mix evenly to obtain silicon-containing Bacterial cellulose slurry; wherein, the addition of silicon is 50wt.% of bacterial cellulose, and the addition of surfactant is 40wt.% of silicon;

[0054] (3) Pour the bacterial cellulose slurry and the silicon-containing bacterial cellulose slurry into a Buchner funnel for suction filtration and stack them alternately to obtain a silicon-containing bacterial cellulose film; the number of superimposed layers is 7 layers, the uppermost layer and the lowermost layer are all layers of the bacterial cellulose slurry, the thickness of the bacterial cellulose slurry is 0.5mm, and the thickness of the silicon-containing bacterial cellulose slurry layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com