Pt/ZnO composite hollow microsphere photocatalysis material and preparation method

A technology of hollow microspheres and reaction raw materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of cumbersome preparation process and inability to realize one-step synthesis of Pt/ZnO composite hollow microspheres , to achieve the effect of simple preparation process, good industrial application prospect and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

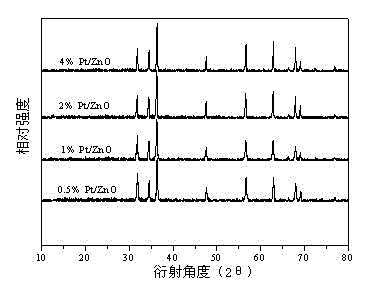

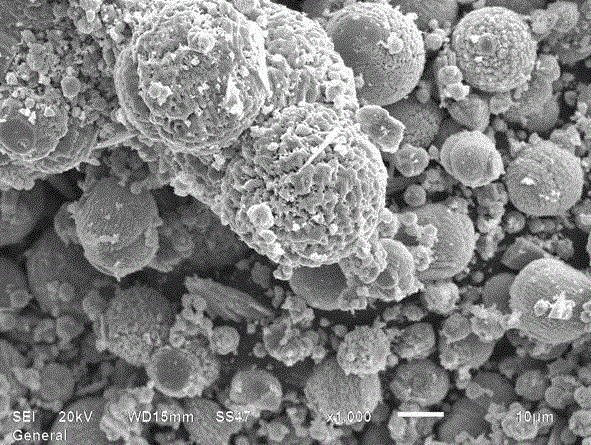

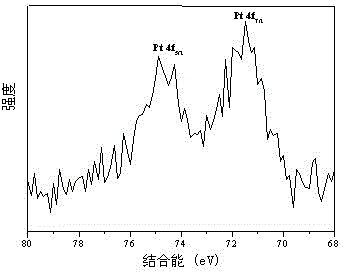

Embodiment 1

[0040] Add 1 g of polyethylene glycol with a molecular weight of 6,000 to 30 g of ethylene glycol, and stir to dissolve to form a solvent. Then 4.065 g of zinc acetate (Zn(CH 3 COO) 2 2H 2 O) and 0.0199 g of chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) Add the above solvent and stir with a magnetic stirrer for 2 hours, transfer to a hydrothermal reaction kettle and treat at 180°C for 10 hours, cool, centrifuge, rinse with distilled water and ethanol for 3 times, and then dry at 100°C for 12 hours. The corresponding Pt (0.5%) / ZnO composite hollow microsphere photocatalytic material was obtained, and its characteristics and degradation rate are shown in Table 1 to Table 2.

Embodiment 2

[0042] Add 1 g of polyethylene glycol with a molecular weight of 6,000 to 30 g of ethylene glycol, and stir to dissolve to form a solvent. Then 4.065 g of zinc acetate (Zn(CH 3 COO) 2 2H 2 O) and 0.0398 g of chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) Add the above solvent and stir with a magnetic stirrer for 2 hours, transfer to a hydrothermal reaction kettle and treat at 180°C for 10 hours, cool, centrifuge, rinse with distilled water and ethanol for 3 times, and then dry at 100°C for 12 hours. The corresponding Pt (1%) / ZnO composite hollow microsphere photocatalytic material was obtained, and its characteristics and degradation rate are shown in Table 1 to Table 2. The cycle performance is shown in Table 3 to Table 4.

Embodiment 3

[0044] Add 1 g of polyethylene glycol with a molecular weight of 6,000 to 30 g of ethylene glycol, and stir to dissolve to form a solvent. Then 4.065 g of zinc acetate (Zn(CH 3 COO) 2 2H 2 O) and 0.0796 g of chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) Add the above solvent and stir with a magnetic stirrer for 2 hours, transfer to a hydrothermal reaction kettle and treat at 180°C for 10 hours, cool, centrifuge, rinse with distilled water and ethanol for 3 times, and then dry at 100°C for 12 hours. The corresponding Pt (2%) / ZnO composite hollow microsphere photocatalytic material was obtained, and its characteristics and degradation rate are shown in Table 1 to Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com