Tailing sand biological prefabricated product and preparation method thereof

A kind of tailings and biological technology, applied in the field of microbiology and building materials, can solve the problems of destroying the soil environment, affecting stability, and causing great harm, and achieve the effects of clean environment, good mechanical strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

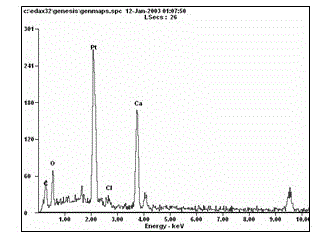

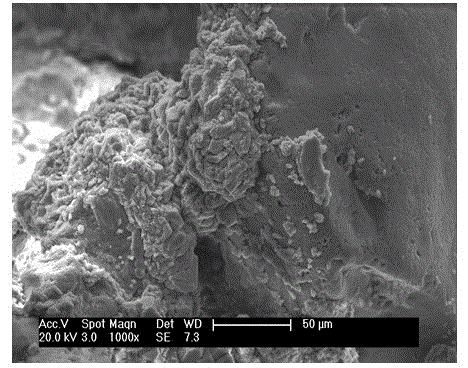

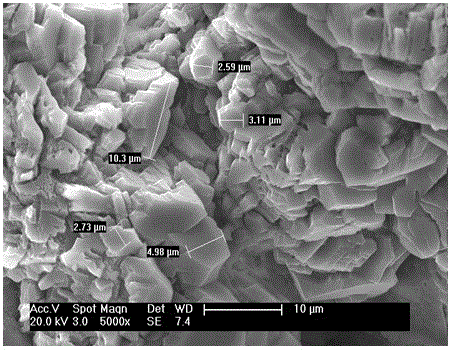

Image

Examples

Embodiment 1

[0030] (1) Weigh 5g of soybean protein, 15g of casein and 1000ml of distilled water to prepare a medium, adjust the pH to 7.0, sterilize and dry, inoculate the prepared medium with Bacillus Pasteurella, and shake it at 30°C Cultivate with an oscillation frequency of 170r / min, and cultivate for 24 hours;

[0031] (2) Configure the concentration of urea solution to be 2 mol L -1 , CaCl 2 The solution concentration is 2mol L -1 mixed solution;

[0032] (3) Put the untreated tailings into a 60ml disposable syringe in 3 times, tap the outside of the syringe during each filling process, so that the loaded sand can be packed tightly, and the sand column can be obtained by passing the test. The porosity is about 48.5%;

[0033] (4) Connect the bottom of the syringe with a peristaltic pump, inject the bacterial solution at a rate of 5ml / min, let it stand for 2 hours after filling, and inject the mixed solution at a rate of 15ml / min after the bacterial solution is completely seeped ...

Embodiment 2

[0036] (1) Weigh 7g of soybean protein, 18g of casein and 1000ml of distilled water to prepare a medium, adjust the pH to 8.0, sterilize and dry, inoculate the prepared medium with Bacillus pasteurianus, and shake at 30°C Cultivate with an oscillation frequency of 170r / min, and cultivate for 20h;

[0037] (2) Configure the concentration of urea solution to be 2 mol L -1 , CaCl 2 The solution concentration is 1.5mol L -1 mixed solution;

[0038] (3) Compact the untreated tailings into a self-made mold with a size of 240*115*53mm, so that the loaded sand can be packed tightly, and the porosity of the sand column can be found to be about 48.5% through testing;

[0039] (4) Connect the bottom of the syringe with a peristaltic pump, inject the bacterial solution at a rate of 10ml / min, and let it stand for 1 hour after it is filled. After the bacterial solution has completely seeped out, inject the mixed solution at a rate of 15ml / min. Leave it for 3 hours. After the mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com