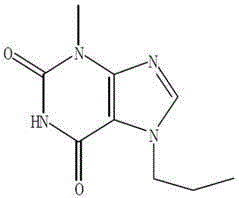

Preparation method of 3-methyl-7-propylxanthine

A technology of propylxanthine and methylxanthine, applied in the direction of organic chemistry, can solve the problems of unsuitability for industrial production, harsh reaction conditions, strong acidity, etc., and achieve good economic benefits, simple reaction steps, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

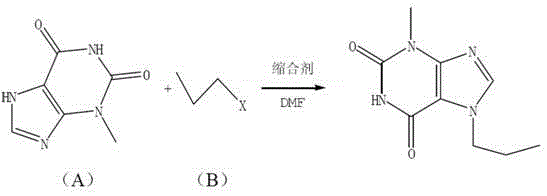

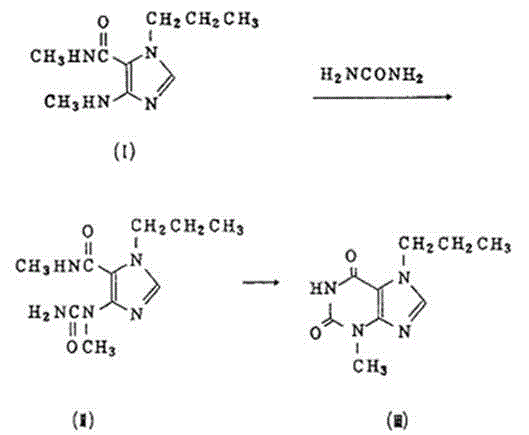

Method used

Image

Examples

Embodiment 1

[0026] Add 16.6g (100mmol) of 3-methylxanthine, 14g (101mmol) of potassium carbonate, 0.83g (5mmol) of potassium iodide, and 330g (4.5mol) of DMF into a 500ml four-necked flask, heat to 45°C, and dropwise add 7.4g of bromopropane (60mmol), the dropwise addition time is 20min, after the dropwise addition, the temperature is raised to 90°C and kept for 1h.

[0027] After the reaction, the DMF was distilled off to obtain the crude product. After dissolving the crude product with 1mol / L sodium hydroxide solution, add 1 g of activated carbon, keep it warm at 80°C for 0.5h, and filter; add hydrochloric acid to the filtrate to adjust the pH to 5, and cool to 0°C. Suction filtration; add a small amount of water to the filter cake, stir and heat up to 60°C, add sodium hydroxide solution to dissolve it. Add 1 g of activated carbon, incubate at 80°C for 1 hour, decolorize, and filter; add hydrochloric acid to the filtrate to adjust pH to 5, cool to 0°C, filter with suction, and dry to ob...

Embodiment 2

[0029] Add 44g (265mmol) of 3-methylxanthine, 28.3g (267mmol) of sodium carbonate, 1.3g (13mmol) of sodium bromide, and 352g (4.8mol) of DMF into a 500ml four-neck flask, heat to 60°C, drop 65.2 g (530 mmol) of bromopropane, the time for the dropwise addition is 40 minutes, after the addition, the temperature is raised to 100°C, and the temperature is kept for 2.5 hours.

[0030] After the reaction, the DMF was distilled off to obtain the crude product. After the crude product was dissolved with 1mol / L sodium hydroxide solution, 1 g of activated carbon was added, and kept at 80°C for 2 hours, decolorized, and filtered while it was hot; the filtrate was adjusted to pH 7 by adding hydrochloric acid, and cooled to Suction filtration at 45°C; stir the filter cake with a small amount of water, heat up to 60°C, add sodium hydroxide solution to dissolve it. Add 1 g of activated carbon, keep warm at 80°C for 1 hour, decolorize, and filter while hot; add hydrochloric acid to the filtra...

Embodiment 3

[0032] Add 49.8g (300mmol) of 3-methylxanthine, 41.5g (301mmol) of potassium carbonate, 1.12g (15mmol) of potassium chloride, and 249g (3.4mol) of DMF into a 500ml four-neck flask, heat to 75°C, drop Chloropropane 47.1g (600mmol), the dropwise addition time is 60min, after the dropwise addition, the temperature is raised to 110°C, and the temperature is kept for 2h.

[0033] After the reaction, the DMF was distilled off to obtain the crude product. After dissolving the crude product with 1mol / L sodium hydroxide solution, add 1 g of activated carbon, keep it at 60°C for 4 hours, decolorize, and filter hot; add sulfuric acid to the filtrate to adjust the pH to 6, and cool down to 20 ℃, filter with suction; add a small amount of water to the filter cake, stir, heat up to 60 ℃, add sodium hydroxide solution to dissolve it. Add 1 g of activated carbon, keep warm at 60°C for 2 hours, decolorize, and heat filter; add sulfuric acid to the filtrate to adjust pH to 6, cool to 25°C and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com