Method for preparing scaling inhibitor

A scale inhibitor and intermediate technology, applied in the field of scale inhibitor preparation, can solve the problems of high production cost and influence on promotion, and achieve the effect of good effect, high benefit and excellent scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

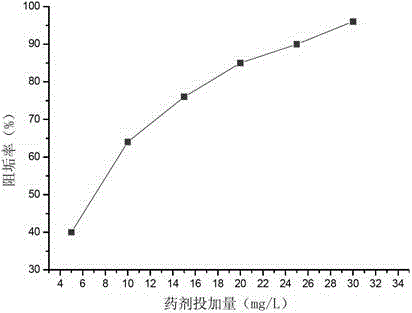

Embodiment 1

[0034] The first step: the preparation of intermediate A

[0035] In parts by mass, add 6 parts of polyamino compounds and 200 parts of distilled water to a reactor equipped with a stirrer, a thermometer and a condensing device, mix well and heat up to 50°C, then slowly add 47 parts by mass to the reactor The fraction is 40% glyoxylate solution, control the pH at 8 after the dropwise addition, and continue the insulation reaction for 4h to obtain intermediate A, the glyoxylate solution is sodium glyoxylate aqueous solution, and the polyamino compound is Melamine;

[0036] The second step: the preparation of intermediate B

[0037] Add 7 parts of glyoxal aqueous solution with a mass fraction of 40% to intermediate A, mix evenly and then raise the temperature to 40° C. for 0.5 h to obtain intermediate B. During the reaction, the pH is controlled at 7.5;

[0038] The third step: preparation of the target product

[0039] Add 20 parts of hydrolyzed protein to intermediate B, mi...

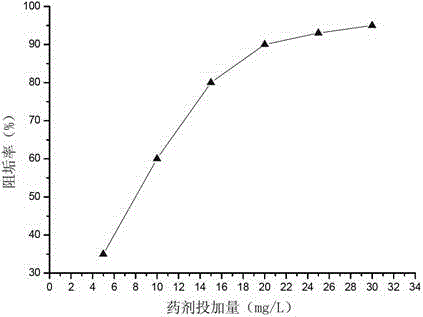

Embodiment 2

[0041] The first step: the preparation of intermediate A

[0042] In parts by mass, add 6 parts of polyamino compounds and 300 parts of distilled water to a reactor equipped with a stirrer, a thermometer and a condensing device, mix well and heat up to 60°C, then slowly add 37 parts by mass to the reactor The fraction is 40% glyoxylate solution, control the pH at 8 after the dropwise addition, and continue the insulation reaction for 3h to obtain intermediate A, the glyoxylate solution is an aqueous solution of potassium glyoxylate, and the polyamino compound is Diethylenetriamine;

[0043] The second step: the preparation of intermediate B

[0044] Add 14.5 parts of glyoxal aqueous solution with a mass fraction of 40% to intermediate A, mix evenly and then raise the temperature to 50°C for 2 hours to obtain intermediate B, and control the pH at 7.5 during the reaction;

[0045] The third step: preparation of the target product

[0046] Add 20 parts of hydrolyzed protein to...

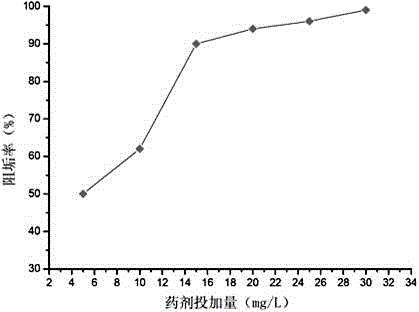

Embodiment 3

[0048] The first step: the preparation of intermediate A

[0049] In parts by mass, add 21 parts of polyamino compounds and 200 parts of distilled water to a reactor equipped with a stirrer, a thermometer and a condensing device, mix well and heat up to 60°C, then slowly add 76 parts by mass to the reactor The fraction is 40% glyoxylate solution, after the dropwise addition, the pH is controlled at 8, and the insulation reaction is continued for 3 hours to obtain intermediate A. The glyoxylate solution is ammonium glyoxylate aqueous solution, and the polyamino compound is Triethylenetetramine;

[0050] The second step: the preparation of intermediate B

[0051] Add 29 parts of glyoxal aqueous solution with a mass fraction of 40% to intermediate B, mix evenly and then raise the temperature to 50°C for 2 hours to obtain intermediate B, and control the pH at 9 during the reaction;

[0052] The third step: preparation of the target product

[0053]Add 20 parts of hydrolyzed pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com