Thorn-shaped grounded de-noising element of micro motor rotor

A micro-motor and rotor technology, applied in electrical components, electric components, connection with grounding devices, etc., can solve the problems of welding head alignment, difficulty in moving welding, not providing a good grounding path, and the disturbance level exceeding the limit value, etc. Achieve the effect of excellent removal and inhibition ability, high performance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Prepare the raw materials for spine-shaped substrates

[0036] Through the optimization scheme of material type, proportion, and substrate shape design, micro-motor rotor spine-shaped grounding noise-canceling component products with different characteristics can be obtained. The product has good performance stability and a large space for performance expansion. This embodiment adopts the semiconductor electronic ceramic substrate material of strontium titanate, and the formula includes: 35% TiO 2 , 20% SrO, 25% BaO, 11% CaO, 0.4% Fe 2 o 3 , 0.6% rare earth oxide materials, which are mixed and ground and dried into powder to make substrate raw materials.

[0037] (2) Manufacturing process of spine-shaped substrate

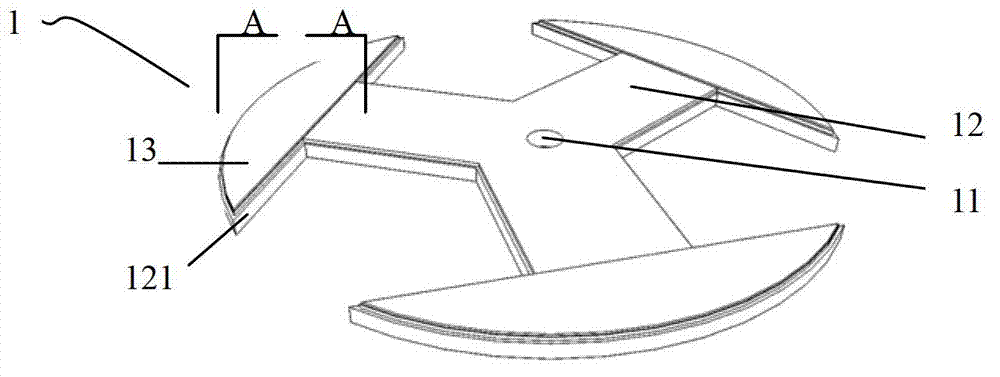

[0038] In this embodiment, a dry pressing die is used to press the green sheet, and the structure is as follows image 3 As shown, the ratchet-shaped substrate has three ratchets 12 evenly distributed radially on the circumference, and the end 121 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com