Probiotics fermentation milk

A technology of probiotics and fermented milk, applied in the field of probiotics fermented milk and its preparation, can solve the problems of low efficacy and inability to colonize the intestines in large quantities, and achieve the effects of promoting growth and value-added, good immunity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

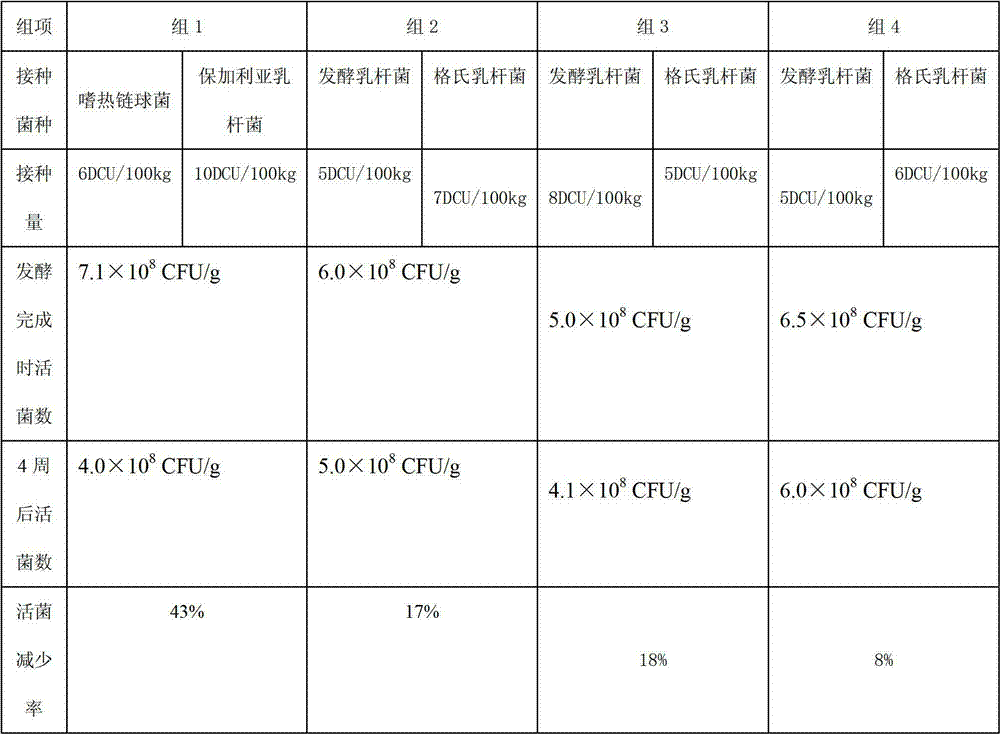

[0021] The invention can ensure the experimental data that the number of live bacteria maintains a relatively high level within the shelf life.

[0022] In Table 1, on the basis of Group 1, Group 2, Group 3, and Group 4 were inoculated with Lactobacillus fermentum and Lactobacillus gasseri, fermented for 4 hours, and stored at 4°C for 4 weeks.

[0023] Table 1

[0024]

[0025] It can be seen that the number of probiotics in the fermented milk inoculated with Lactobacillus fermentum and Lactobacillus gasseri remained at a high level within 4 weeks.

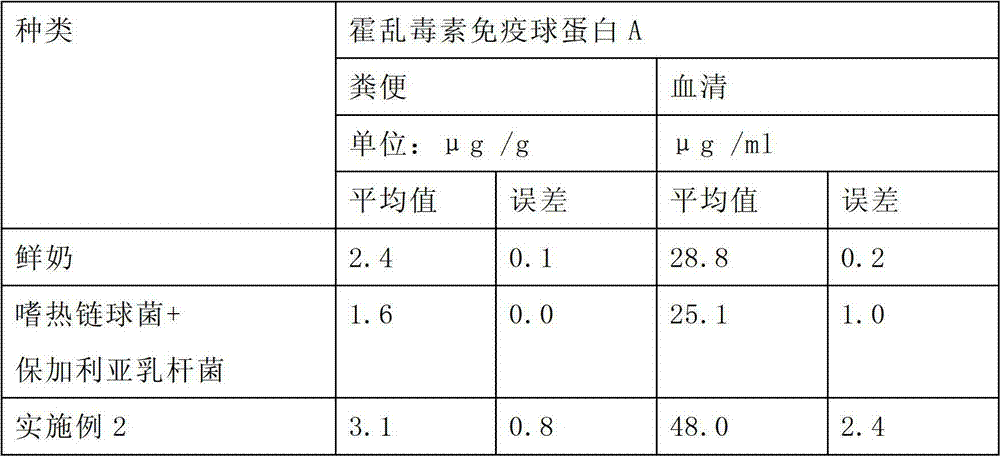

Embodiment 2

[0027] A. Mix 90wt% fresh milk, 8wt% sucrose and 1wt% fructooligosaccharide, add 1wt% phytosterol, mix evenly, carry out vacuum degassing treatment, temperature 65°C, vacuum degree 0.5bar; preheat to 60°C , with a pressure of 15mpa for homogenization; sterilize at 95-℃ for 5 minutes, and cool to 40℃.

[0028] B. Carry out strain inoculation under sterile conditions, first inoculate Lactobacillus bulgaricus and Streptococcus thermophilus, then inoculate Lactobacillus fermentum and Lactobacillus gasseri after 30 minutes, the inoculation amount of Lactobacillus fermentum is 5DCU / 100kg, the inoculation amount of Lactobacillus gasseri 6DCU / 100kg, Lactobacillus bulgaricus inoculation amount 6DCU / 100kg, Streptococcus thermophilus inoculum amount 9DCU / 100kg; stir at 50 rpm for 5min, keep warm at 40°C for fermentation.

[0029] C. When the acidity of the fermented milk reaches 60°T, cool it to 4°C with ice water, stir for 4 minutes at a stirring speed of 50 rpm; cool down to 20°C, fill...

Embodiment 3

[0046] A. Mix 94wt% fresh milk, 4.9wt% sucrose and 0.5wt% fructooligosaccharide, add 0.6wt% phytosterol, mix evenly, carry out vacuum degassing treatment, temperature 75 ° C, vacuum degree 0.7 bar; preheat Homogenize at 65°C with a pressure of 20mpa; sterilize at 98°C for 5 minutes, and cool to 45°C.

[0047] B. Carry out strain inoculation under aseptic condition, first inoculate Lactobacillus bulgaricus and Streptococcus thermophilus, inoculate Lactobacillus fermentum and Lactobacillus gasseri after 30-60min, the inoculum amount of Lactobacillus fermentum is 10DCU / 100kg, described Grassella The inoculation amount of Lactobacillus 5-8DCU / 100kg, the inoculation amount of Lactobacillus bulgaricus 7DCU / 100kg, the inoculation amount of Streptococcus thermophilus 11DCU / 100kg; stir at 50-80 rpm for 5min, keep warm at 45°C for fermentation.

[0048] C. When the acidity of fermented lactic acid reaches 60°T, cool it to 6°C with ice water, stir for 6 minutes at a stirring speed of 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com