Moisturizing cream containing natural olive oil and derivatives of natural olive oil, and preparation method of moisturizing cream

A technology of olive oil and moisturizing cream, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., to maintain tenderness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

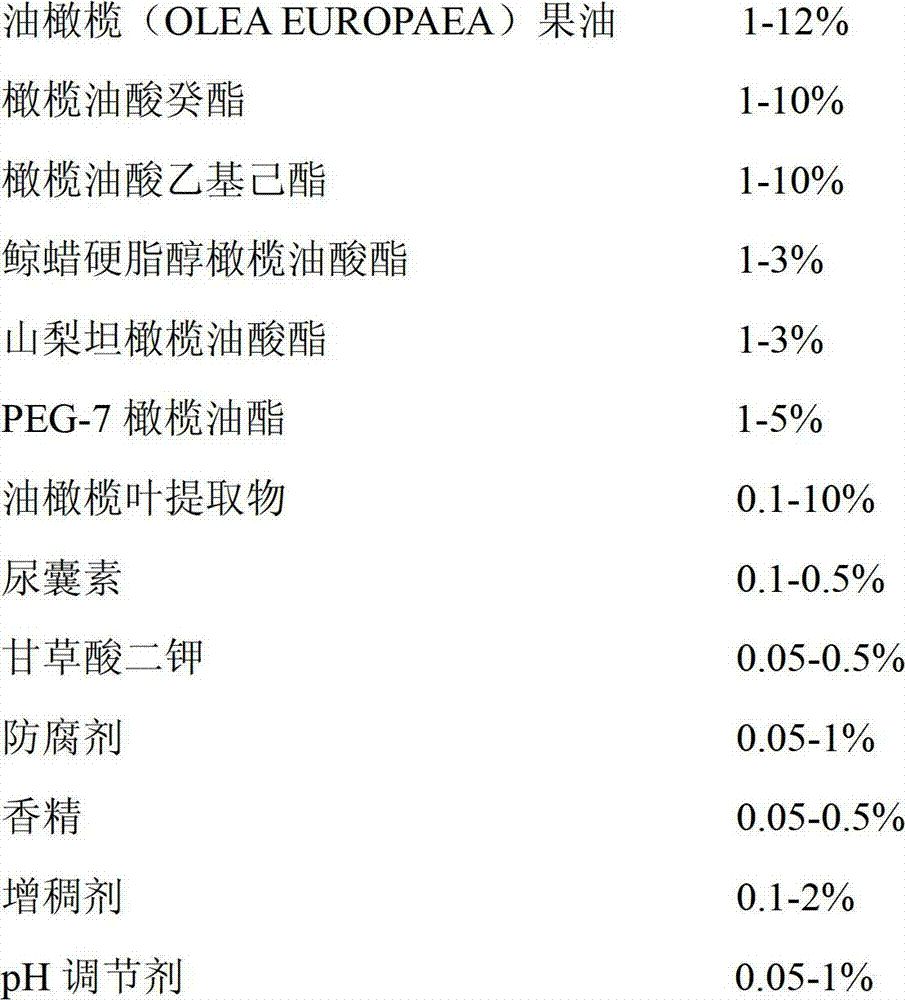

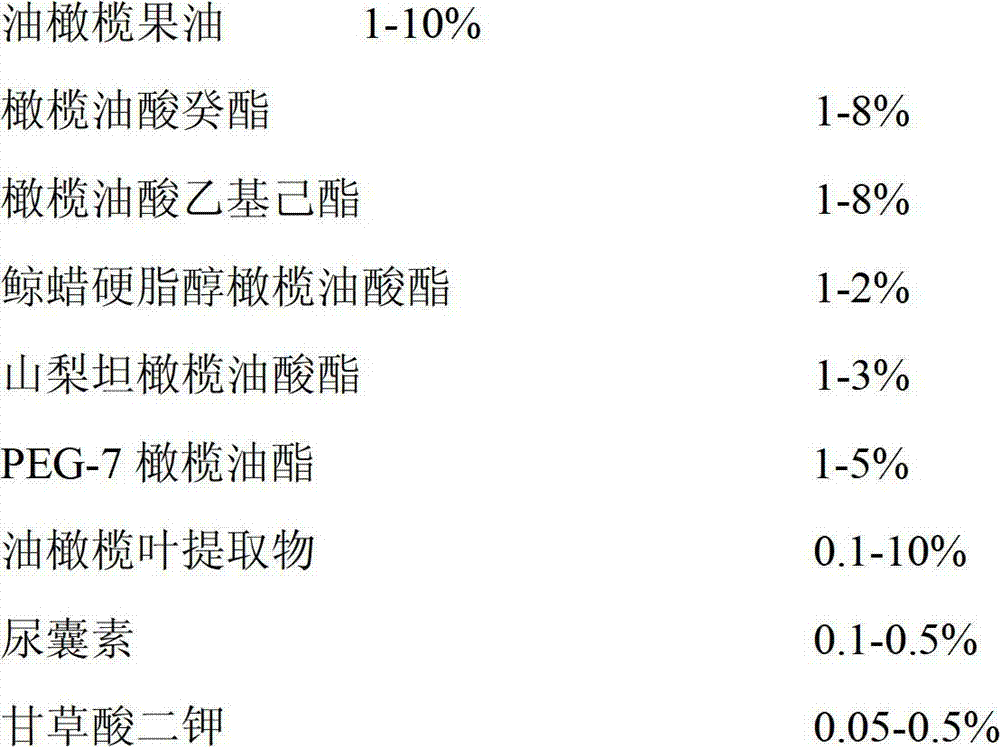

Method used

Image

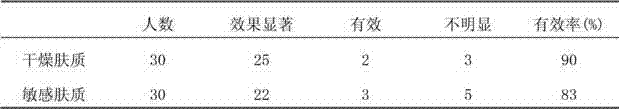

Examples

Embodiment 1

[0046] The mass percentage of each raw material component of moisturizing cream: olive fruit oil 8%; decyl olive oil 2%; ethylhexyl olive oil 6%; cetearyl olive oil 2%; Olive oil ester 1.5%; PEG-7 olive oil ester 2%; olive leaf extract 3%; allantoin 0.1%; dipotassium glycyrrhizinate 0.1%; potassium sorbate 0.05%; essence 0.1%; guar polysaccharide gum (for natural guar gum) 0.2%; citric acid 0.05%; the rest is deionized water, the sum of the contents of each component is 100%.

[0047] Preparation:

[0048] (1) Weigh the raw materials according to the weight percentage of the formula;

[0049] (2) Heat the deionized water to 90°C in the water phase pot, take PEG-7 olive oil ester, allantoin, dipotassium glycyrrhizinate, and guar gum and stir in the pot to dissolve evenly; then pump into the vacuum emulsification in the pot;

[0050] (3) Heat olive fruit oil, decyl olivate, ethylhexyl olivate, cetearyl olivate, and sorbitan olivate in an oil pan to 80°C, and stir well , and...

Embodiment 2

[0058]The mass percentage of each raw material component of moisturizing cream: oleocanthal oil 6%; decyl olivate 6%; ethylhexyl olivate 1.5%; Olivate 1.3%; PEG-7 olive oil ester 2.5%; olive leaf extract 7.5%; allantoin 0.2%; dipotassium glycyrrhizinate 0.15%; sodium benzoate 0.05%; essence 0.08%; locust bean polysaccharide gum ( natural locust bean gum) 0.2%; malic acid 0.05%; the rest is deionized water, and the sum of the contents of each component is 100%.

[0059] Preparation:

[0060] (1) Weigh the raw materials according to the mass percentage of the formula;

[0061] (2) Heat the deionized water to 80°C in the water phase pot, take PEG-7 olive oil ester, allantoin, dipotassium glycyrrhizinate, and locust bean polysaccharide gum and stir in the pot to dissolve evenly; then pump into the vacuum in the emulsifying pot;

[0062] (3) Heat olive fruit oil, decyl olivate, ethylhexyl olivate, cetearyl olivate, and sorbitan olivate in an oil pan to 60°C, and stir well , an...

Embodiment 3

[0070] The mass percentage of each raw material component of moisturizing cream: olive fruit oil 5%; decyl olivate 8%; ethylhexyl olivate 3%; cetearyl olive oleate 1%; Olivate 1%; PEG-7 olive oil ester 2%; olive leaf extract 5%; allantoin 0.1%; dipotassium glycyrrhizinate 0.3%; sodium paraben 0.06%; essence 0.1%; acacia polysaccharide Glue (natural acacia gum) 0.15%; triethanolamine 0.08%; the rest is deionized water, the sum of the contents of each component is 100%.

[0071] Preparation:

[0072] (1) Weigh the raw materials according to the weight percentage of the formula;

[0073] (2) Heat the deionized water to 90°C in the water phase pot, take PEG-7 olive oil ester, allantoin, dipotassium glycyrrhizinate, and acacia polysaccharide gum and stir in the pot to dissolve evenly; then pump it into the vacuum emulsification in the pot;

[0074] (3) Heat olive fruit oil, decyl olivate, ethylhexyl olivate, cetearyl olivate, and sorbitan olivate in an oil pan to 60°C, and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com