Production technique for high-purity nanoscale metal magnesium powder

A production process, metal magnesium technology, applied in the production process field of high-purity nano-scale metal magnesium powder, can solve the problems of complex equipment structure, difficulty in powder collection, inconvenient operation, etc., achieve good separation effect, simple process route design, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

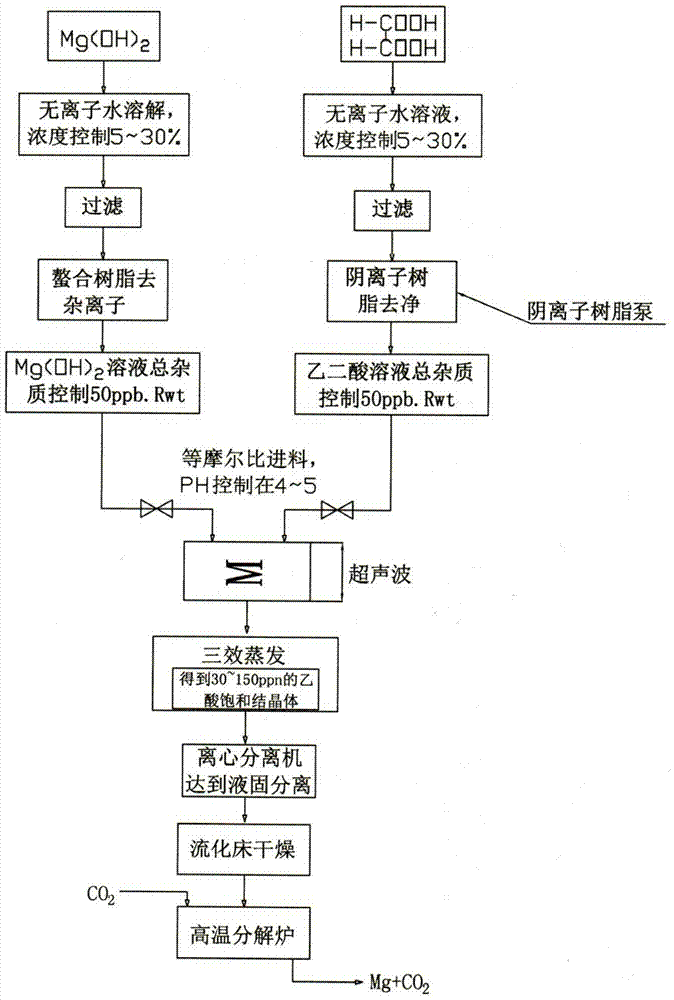

Method used

Image

Examples

Embodiment 1

[0028] Weigh 150 grams of commercially available reagent grade Mg(OH) 2 To prepare a solution, weigh 150 grams of commercially available reagent grade oxalic acid to prepare a solution. The reactor containing the magnesium hydroxide solution is placed on a magnetic stirrer and stirred with an external ultrasonic wave instrument, the frequency is 21KHz, and the output power is 0.8KW. Add oxalic acid solution dropwise to generate magnesium oxalate. The water in the reaction liquid was evaporated and filtered to obtain fine particle crystals of magnesium oxalate. After drying the magnesium oxalate fine particle crystals in a horse temperature furnace, place the magnesium oxalate fine particle crystals in a high-purity quartz glass tube, cover both ends with high-purity graphite, and then place them in the horse temperature furnace To obtain a mixture of metal magnesium powder and carbon dioxide gas, and gas-solid separation to obtain magnesium powder. Magnesium powder particles ...

Embodiment 2

[0030] Weigh 150 grams of commercially available reagent grade Mg(OH) 2 To prepare a solution, weigh 150 grams of commercially available reagent grade oxalic acid to prepare a solution. The reactor containing the magnesium hydroxide solution is placed on a magnetic stirrer and stirred with an external ultrasonic wave instrument, the frequency is 140KHz, and the output power is 0.8KW. The oxalic acid solution is added dropwise to react to generate magnesium oxalate. The water in the reaction liquid was evaporated and filtered to obtain fine particle crystals of magnesium oxalate. After drying the magnesium oxalate fine particle crystals in a horse temperature furnace, place the magnesium oxalate fine particle crystals in a high-purity quartz glass tube, cover both ends with high-purity graphite, and then place them in the horse temperature furnace To obtain a mixture of metal magnesium powder and carbon dioxide gas, and gas-solid separation to obtain magnesium powder. Magnesiu...

Embodiment 3

[0032] Weigh 150 grams of commercially available reagent grade Mg(OH) 2 Prepare a 5% solution, weigh 150 grams of commercially available reagent grade oxalic acid to prepare a 5% solution. The reactor containing the magnesium hydroxide solution was placed on a magnetic stirrer and stirred at a stirring rate of 3000 revolutions per minute. The external ultrasound device has a frequency of 130KHz and an output power of 0.8KW. Add oxalic acid solution dropwise to generate magnesium oxalate. The water in the reaction liquid was evaporated and filtered to obtain fine particle crystals of magnesium oxalate. After drying the magnesium oxalate fine particle crystals at 90℃ in a horse temperature furnace, place the magnesium oxalate fine particle crystals in a high-purity quartz glass tube, cover both ends with high-purity graphite, and then place them in the horse temperature furnace For high-temperature gasification, the high-temperature gasification temperature is 550°C, and the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com